Reinforced concrete drainage pipe and manufacturing mold thereof

A reinforced concrete and mold manufacturing technology, which is applied in the field of cement pipes, can solve the problems of long mold occupation time, damage to cement pipes, and inability to demould immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

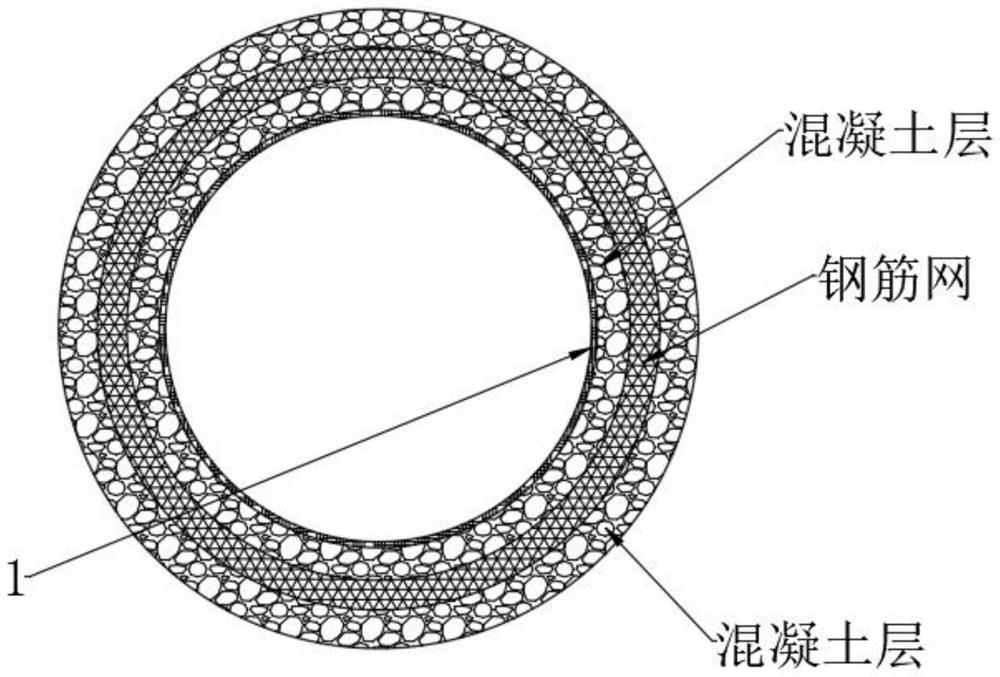

[0046] see Figure 1-9 , a reinforced concrete drainpipe and its manufacturing mold, including the drainpipe, see figure 1 , the drainage pipes are concrete layer, steel mesh, concrete layer and anti-corrosion and impermeable membrane 1 from outside to inside. The total thickness of concrete layer and steel mesh is 8-10cm, and the steel mesh is located in the middle of the concrete layer, which can ensure The compressive capacity of the cement pipe, the concrete is acid-resistant concrete, is to improve the corrosion resistance, and the anti-corrosion and impermeable membrane 1 is made of stretch-resistant elastic foamed polyurethane material, which is to offset the tensile stress of the concrete when it is dry and avoid damage. , and the thickness of the anti-corrosion and impermeable membrane 1 is 5-10 mm;

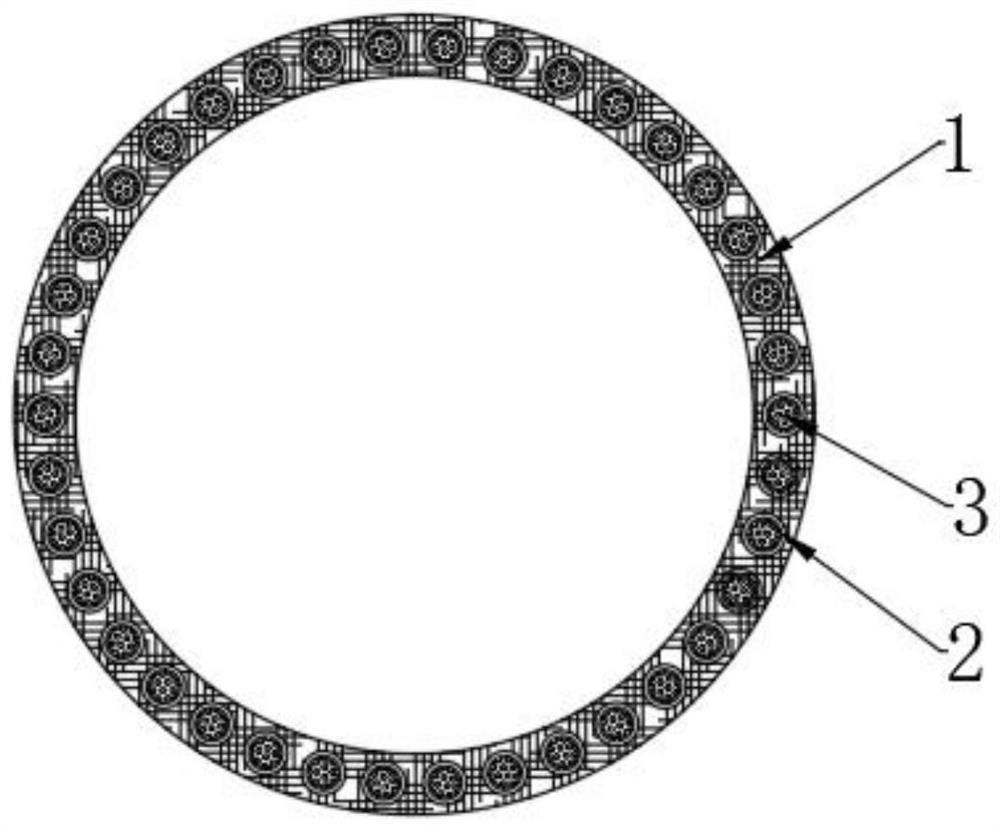

[0047] see Figure 2-4 The interior of the anti-corrosion and impermeable membrane 1 is provided with a plurality of cavities 2 arranged at equal intervals. Anti-corro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com