Iron-based composite desulfurizing agent and preparation method thereof and application of iron-based composite desulfurizing agent in removal of hydrogen sulfide in gas

A degassing, composite technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

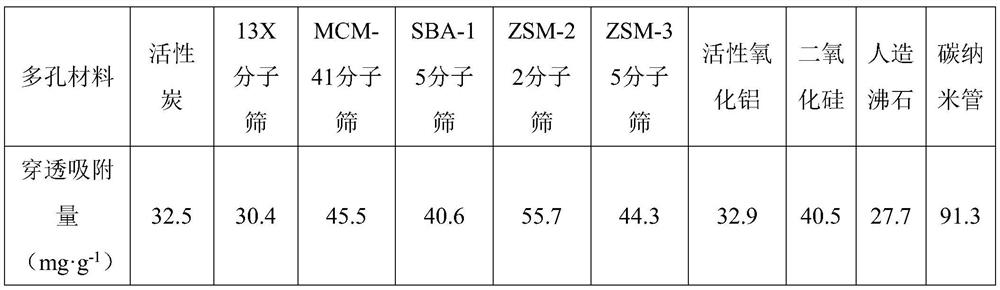

Embodiment 1

[0043] (1) FeCl 3 ·6H 2 O is completely dissolved in deionized water to form an iron salt solution, and the iron ion concentration in the iron salt solution is 0.1mol / L;

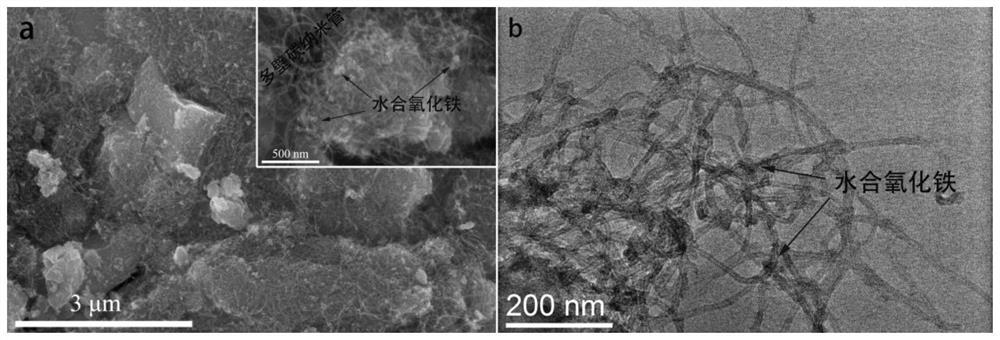

[0044] (2) adding multi-walled carbon nanotubes to the iron salt solution, stirring evenly to obtain a mixed solution, ultrasonically treating the mixed solution for 1 hour, and then transferring to a water bath and heating to 25° C.;

[0045] (3) Under constant stirring, add a potassium hydroxide solution with a concentration of 1mol / L as a precipitating agent to the above mixed solution, adjust the pH to 7, and form a suspension; age the above suspension in the mother liquor for 3 hours, and The heating temperature was 25°C, and continuous stirring was maintained during this period.

[0046] (4) Suction filter the above suspension to collect the precipitate; the obtained precipitate is washed with deionized water, then dried at 100°C for 4 hours, and finally processed into 40-60 mesh by grinding, tableti...

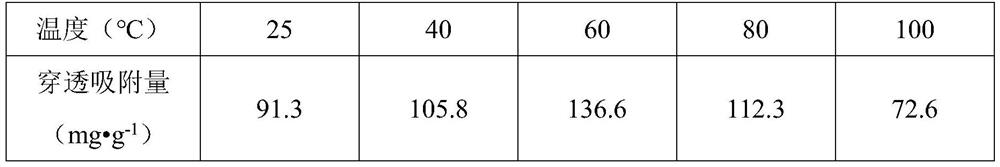

Embodiment 2

[0053] (1) FeCl 3 ·6H 2 O is completely dissolved in deionized water to form an iron salt solution, and the iron ion concentration in the iron salt solution is 0.1mol / L;

[0054] (2) Add multi-walled carbon nanotubes to the above iron salt solution, stir to obtain a mixed solution, ultrasonically treat the mixed solution for 1 hour, then transfer to a water bath and heat to 25, 40, 60, 80 and 100°C respectively ;

[0055] (3) Under constant stirring, add a potassium hydroxide aqueous solution with a concentration of 1mol / L as a precipitating agent to the above mixed solution, adjust the pH to 7, and form a suspension; age the above suspension in the mother liquor for 3 hours, and The heating temperature was 25°C, and continuous stirring was maintained during this period.

[0056] (4) Suction filter the above suspension to collect the precipitate; the obtained precipitate is washed with deionized water, then dried at 100°C for 4 hours, and finally processed into 40-60 mesh b...

Embodiment 3

[0062] (1) FeCl 3 ·6H 2 O is completely dissolved in deionized water to form an iron salt solution, and the iron ion concentration in the iron salt solution is 0.1mol / L;

[0063] (2) adding multi-walled carbon nanotubes to the iron salt solution, and stirring evenly to obtain a mixed solution; ultrasonically treating the mixed solution for 1 hour, then transferring to a water bath and heating to 60° C.;

[0064] (3) Under constant stirring, add a potassium hydroxide aqueous solution with a concentration of 1mol / L as a precipitating agent to the above mixed solution, and adjust the pH to 3, 5, 7, 9 and 11 respectively to form a suspension; Aging in the mother liquor for 3 hours at an aging temperature of 60° C. during which continuous stirring was maintained.

[0065] (4) Suction filter the above suspension to collect the precipitate; the obtained precipitate is washed with deionized water, then dried at 100°C for 4 hours, and finally processed into 40-60 mesh by grinding, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com