A kind of poultry feed and preparation method thereof

A technology for feed and poultry, applied in the field of feed, to achieve the effect of less nutritional antagonistic factors, low preparation cost and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

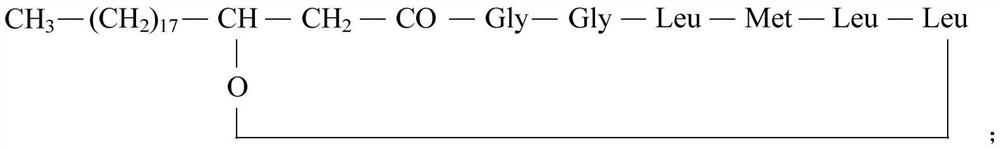

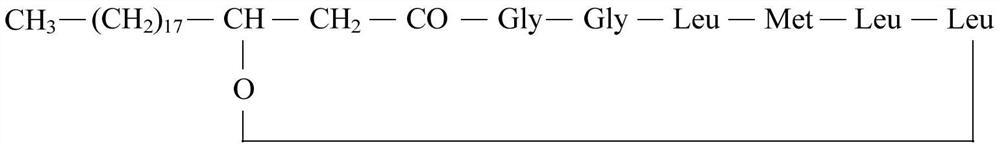

Image

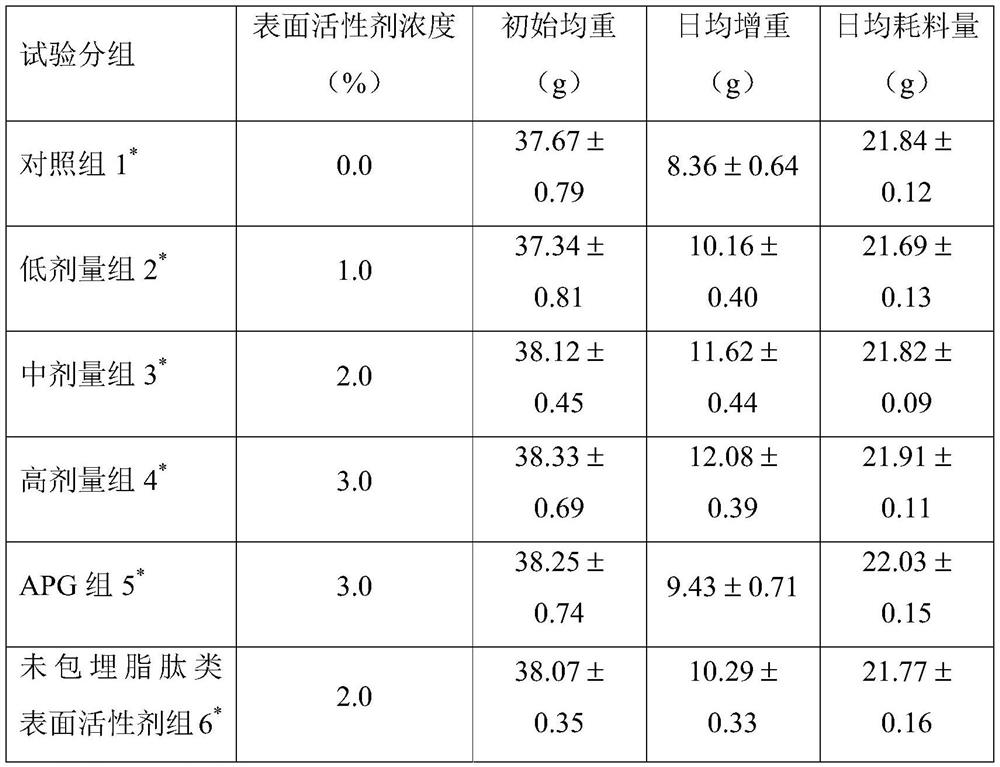

Examples

Embodiment 1

[0055] Embodiment 1 Preparation of lipopeptide microbial surfactant embedded in microcapsules

[0056] (1) Transformation of Achromobacter sp.HZ01-2:

[0057] Through ultraviolet mutagenesis, plasma mutagenesis, ethyl methanesulfonate (EMS) mutagenesis and its compound mutagenesis methods, the yield of lipopeptide surfactant for Achromobacter sp.HZ01 is 0.29~ 0.82g / L) for multiple mutagenesis screening, and then through sheep blood plate primary screening and shake flask fermentation re-screening, a high-yield mutant strain of Achromobacter sp.HZ01-2 with stable genetic characteristics was finally obtained (Achromobacter sp.HZ01-2; lipopeptide Surfactant-like yield is 1.81~2.77g / L).

[0058] (2) Preparation of lipopeptide biosurfactant embedded in microcapsules:

[0059] The transformed Achromobacter sp.HZ01-2 was fermented; then the fermentation supernatant was subjected to ultrafiltration through a 360Da ultrafiltration membrane, and the filtrate was collected; 0.5% ( Sod...

Embodiment 2

[0063] Embodiment 2 Preparation of lipopeptide microbial surfactant embedded in microcapsules

[0064] The transformed Achromobacter sp.HZ01-2 was fermented; then the fermentation supernatant was ultrafiltered through a 1000Da ultrafiltration membrane, and the filtrate was collected; 2% ( Sodium alginate (mass of sodium alginate / volume of filtrate) is spray-dried at an inlet air temperature of 220° C. and a feed rate of 600 mL / h to obtain lipopeptide biosurfactants embedded in microcapsules.

Embodiment 3

[0065] Embodiment 3 Preparation of lipopeptide microbial surfactant embedded in microcapsules

[0066] The transformed Achromobacter sp.HZ01-2 was fermented; then the fermentation supernatant was subjected to ultrafiltration through a 600Da ultrafiltration membrane, and the filtrate was collected; 1.0% ( Sodium alginate (mass of sodium alginate / volume of filtrate) is spray-dried at an inlet air temperature of 180° C. and a feed rate of 350 mL / h to obtain lipopeptide biosurfactants embedded in microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com