A kind of polyhydroxyl air-entraining retarding water reducing agent and preparation method thereof

A technology of retarding and water-reducing agent, which is applied in the field of concrete admixtures to achieve the effects of improving retention time, delaying hydration, and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

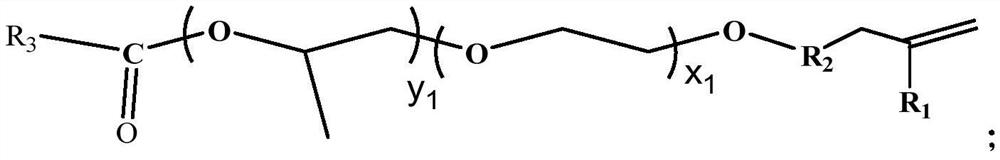

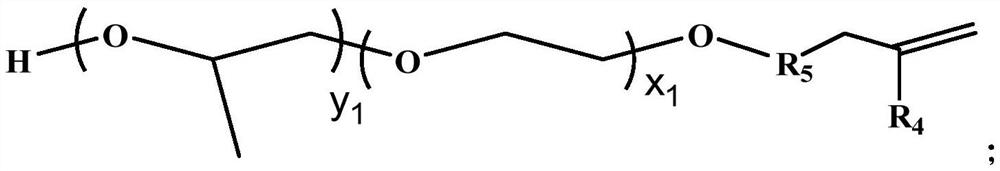

[0041] The invention provides a method for preparing a polyhydroxy air-entraining retarding water reducer, which comprises the following steps:

[0042] Put vinyl ether macromonomer, retarding monomer, reducing agent and appropriate amount of deionized water in the reactor, stir to dissolve, add unsaturated acid, unsaturated ester and air-entraining monomer dropwise into the reactor The mixed solution, oxidant solution and chain transfer agent solution, and adjust the temperature to 5 ~ 15 ° C to react, the dropwise addition time is 0.5 ~ 1h, after the dropwise addition, keep warm for 0.5 ~ 1.5h, after the reaction, use liquid alkali to adjust the pH to 6 to 7, the polyhydroxy air-entraining retarding water reducer is obtained.

[0043] Wherein, the mass ratio of the ether macromonomer, air-entraining monomer, retarding monomer, unsaturated acid, and unsaturated ester is: (0-200): (1-10): (10-200 ): (10~30): (1~10).

[0044] The vinyl ether macromonomer is preferably 4-hydroxy...

Embodiment 1

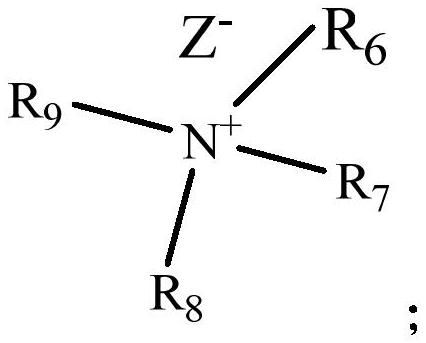

[0064] (1) Preparation of air-entraining monomer B1: 0.1 mol of bis(hydroxyethyl)methyl dodecyl ammonium chloride, 0.1 mol of acryloyl chloride, 40 mL of 1,4 dioxane, and 0.1 mol of pyridine were placed in the reaction In the reactor, under the condition of 15°C, the reaction was carried out for 10 h, and the product was purified by vacuum distillation and recrystallization to obtain the air-entraining monomer B1.

[0065] (2) Preparation of retarding monomer C1: 200 parts of molecular weight 4-hydroxybutyl vinyl polyoxyethylene ether-2400, 15 parts of gluconic acid, 1.0 parts of concentrated sulfuric acid and 0.1 part of p-hydroxyanisole were added to In the first reactor equipped with a condensing device, the temperature was maintained at 120°C for 6 hours under the protection of nitrogen, and the temperature was lowered to 40°C after the reaction was completed to obtain retarded monomer C1.

[0066] (3) Copolymerization reaction: 50 parts of 4-hydroxybutyl vinyl polyoxyethy...

Embodiment 2

[0068] Put 200 parts of retarding monomer C1, 1.5 parts of sodium formaldehyde sulfoxylate and appropriate amount of deionized water in the reactor, stir to dissolve, add 20 parts of acrylic acid, 4 parts of 2-methacryloyl A mixed solution of oxyethylphosphorylcholine, 4 parts of air-entraining monomer B1, 2 parts of hydrogen peroxide solution and 1 part of mercaptopropionic acid solution, and adjust the temperature to 15°C for the reaction. The dropping time is 45 minutes. After the completion of the heat preservation for 1.0h, adjust the pH to 6-7 with liquid caustic soda after the reaction, and obtain the polyhydroxy air-entraining polycarboxylate water reducer PCE-2. Wherein, water consumption is the consumption that makes mother liquor solid content be 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com