Ethylene carbonate continuous melt crystallization device and method

A technology of ethylene carbonate and melt crystallization, which is applied in the directions of crystallization separation, solution crystallization, and crystallization condition screening, etc., can solve the problems that cannot reflect the energy-saving advantages of the crystallization process, unstable product quality, low production efficiency, etc., and achieve structural Compactness, reduced need to sweat, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

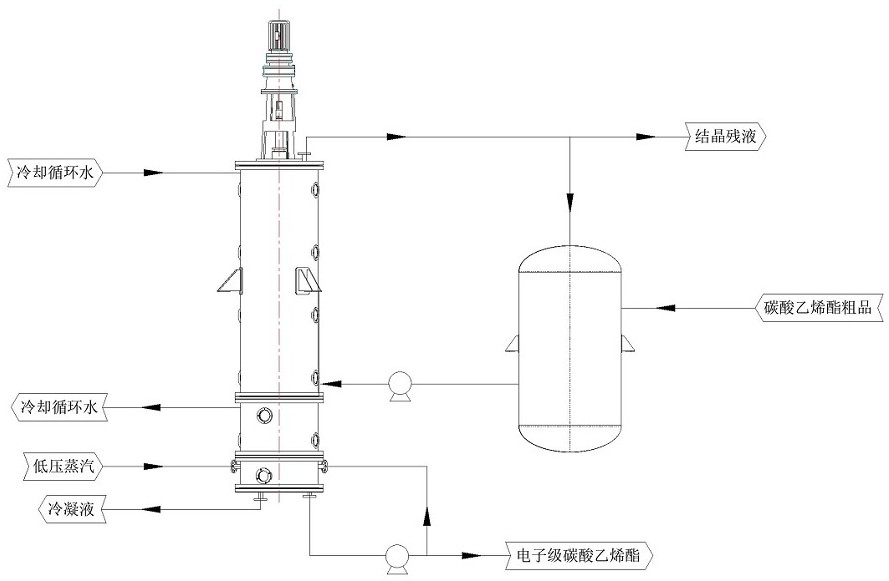

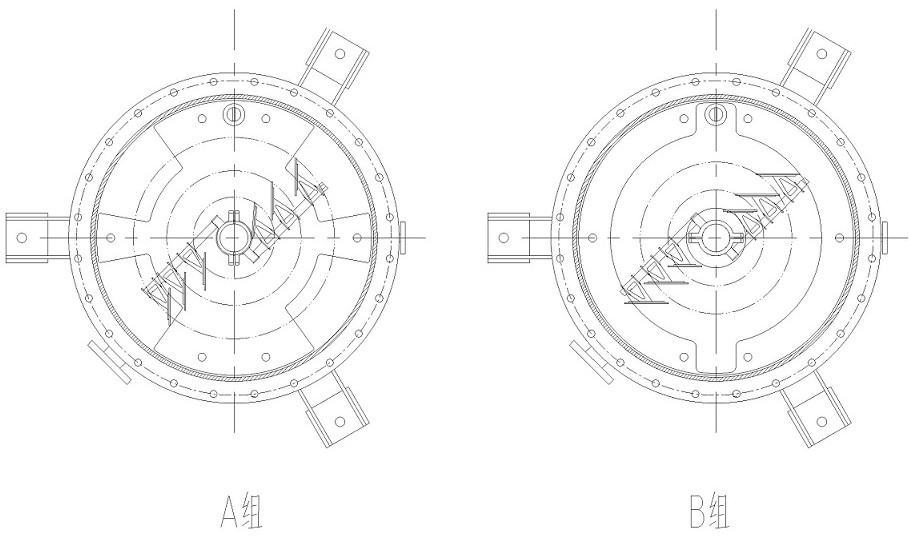

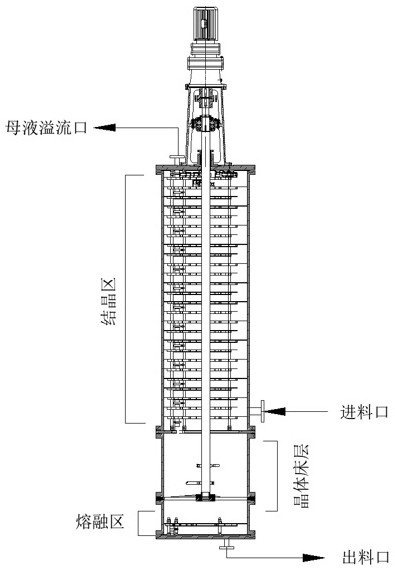

[0038]A ethylene carbonate continuous melting and crystallization equipment is a vertical structure, which is divided into a crystallization area, a crystal bed area and a melting area from top to bottom along the axial direction. The diameter of the equipment is 800mm, the height of the crystallization area is 4000mm, and the height of the crystal bed area is 1500mm , The height of the melting zone is 800mm. Heat exchange fins A and heat exchange fins B are alternately arranged in the crystallization area, and reinforcing ribs are provided inside the heat exchange fins to form a cooling fluid flow channel, and the adjacent heat exchange fins are connected in series. A vertical scraper is arranged between two adjacent heat exchange fins. The top of the heat exchange fin A corresponds to a group of scrapers. The plane of the scraper is perpendicular to the plane of the heat exchange fin and forms an angle of 45 degrees with the connecting rod. When rotating, the scraper pushes t...

Embodiment 2

[0040] Using the pilot equipment listed in Example 1, the superior grade ethylene carbonate with 99.9wt% purity (remaining part is ethylene glycol and other impurities) is a raw material for continuous melting crystallization experiment, the feed flow rate is 1500kg / h, and the feed temperature is 40 ℃, control the flow rate of circulating cooling water and the flow rate of low-pressure steam in the melting zone, so that the discharge rate is 1200kg / h, the overflow rate of the mother liquor is 300kg / h, and the height of the crystal bed can be kept stable, and at the same time, the cold and heat can meet the needs of the melting zone. After the inner crystal melts, the liquid phase reflux ratio is 3. At this time, the heat transfer temperature difference in the crystallization zone is 15°C, and the heat transfer temperature difference in the melting zone is 60°C. After the equipment was running stably for 10 hours, a sample was taken and analyzed. The purity of the product was 99...

Embodiment 3

[0042] Using the pilot equipment listed in Example 1, industrial-grade ethylene carbonate with a purity of 99.5wt% (remaining part is ethylene glycol and other impurities) is used as a raw material for continuous melting and crystallization experiments, and the feed flow rate is controlled to be 1500kg / h. 40°C, control the flow rate of circulating cooling water and the flow rate of low-pressure steam in the melting zone, so that the discharge rate is 720kg / h, the overflow rate of the mother liquor is 780kg / h, and the height of the crystal bed can be kept stable, while the cold heat can meet the requirements of melting The reflux ratio of the liquid phase in the zone is 5 after the crystal melts. At this time, the heat transfer temperature difference in the crystallization zone is 9°C, and the heat transfer temperature difference in the melting zone is 35°C. After the equipment was running stably for 10 hours, sampling and analysis showed that the product had a purity of 99.995w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com