Gas ignition type inner hole supersonic spray gun

A supersonic and inner hole technology, which is applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems such as the difficulty of forming high-speed flame flow, and achieve good economic benefits, reasonable design, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

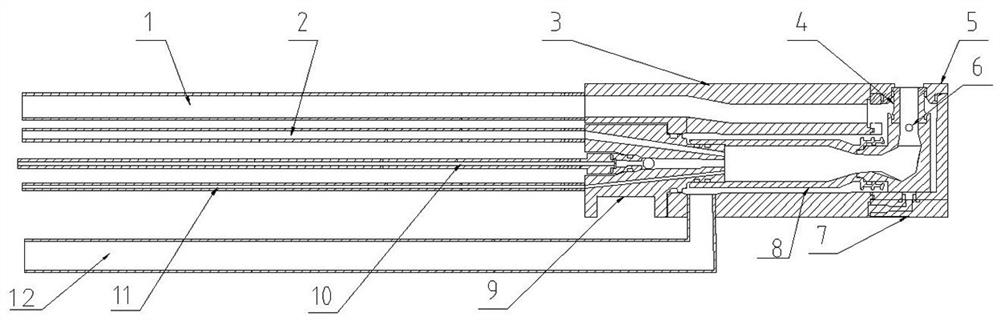

[0012] Example: see figure 1 , in the picture, 1-cooling water inlet pipe, 2-oxygen delivery pipe, 3-gun body, 4-gun barrel, 5-gun barrel pressure cap, 6-powder feeding port, 7-connector, 8-combustion chamber, 9-stabilizer, 10-fuel delivery pipeline, 11-gas delivery pipeline, 12-cooling water outlet pipe.

[0013] A gas ignition type inner hole supersonic spray gun, including a gun body 3, a gun barrel 4, a voltage regulator 9, a combustion chamber 8 and a connector 7, wherein: the combustion chamber 8 is located in the inner cavity of the gun body 3, and the outlet of the combustion chamber 8 It communicates with the gun barrel 4, the gun barrel 4 is located in the inner cavity of the connector 7, and the body wall of the gun barrel 4 is provided with a powder feeding port 69, and an igniter and three gas passages are arranged on it, and the entrances of the three gas passages are respectively connected to the oxygen The delivery pipeline 2, the fuel delivery pipeline 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com