High-permeability matte top-coat coating and preparation method thereof

A transparent matte, clear surface technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor transparency, large surface area, difficult to disperse, etc., to achieve good matte and transparency, good recoating transparency, The effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

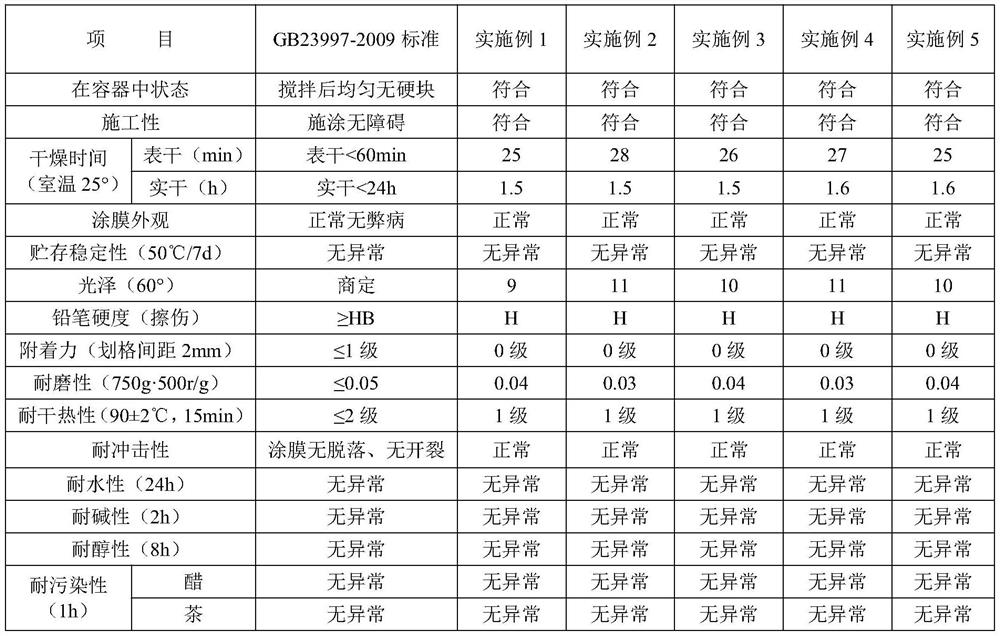

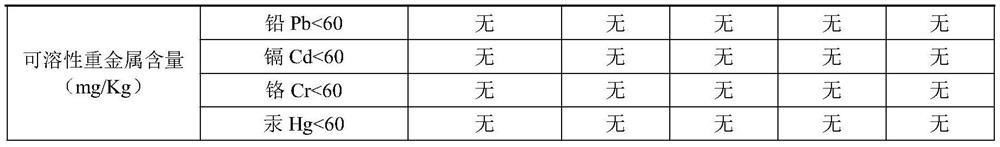

Examples

Embodiment 1

[0029] 1. A high-transparency matt clear finish coating, comprising a main agent, a curing agent and a diluent whose weight ratio is 1:0.5:0.5;

[0030] Among them, the main agent includes 76 parts by weight of alkyd resin, 6 parts of butyl acetate, 6 parts of ethyl acetate, 3 parts of nitrocellulose, 6 parts of organic matting powder, and 0.2 parts of modified silicone defoamer. 0.6 part of polymer dispersant, 2 parts of polyamide wax and 0.2 part of organic leveling agent;

[0031] The diluent comprises 20 parts by weight of dimethylbenzene, 60 parts of butyl acetate and 20 parts of propylene glycol methyl ether acetate;

[0032] The curing agent includes 45 parts of aromatic isocyanate, 25 parts of trimer isocyanate and 30 parts of butyl acetate in parts by weight.

[0033] 2. A preparation method for a high-transparency matte clear coating, comprising the following steps:

[0034] 1) Preparation of the main ingredient: mix alkyd resin, butyl acetate, modified silicone de...

Embodiment 2

[0039] 1. A high-transparency matt clear finish coating, comprising a main agent, a curing agent and a diluent whose weight ratio is 1:0.6:0.8;

[0040] Among them, the main agent includes 75 parts by weight of alkyd resin, 5 parts of butyl acetate, 5 parts of ethyl acetate, 3 parts of nitrocellulose, 8 parts of organic matting powder, and 0.2 parts of modified silicone defoamer. 0.8 parts of polymer dispersant, 2.8 parts of polyamide wax and 0.2 parts of organic leveling agent;

[0041] The diluent comprises 20 parts of xylene, 68 parts of butyl acetate and 12 parts of propylene glycol methyl ether acetate in parts by weight;

[0042] The curing agent includes 40 parts of aromatic isocyanate, 30 parts of trimer isocyanate and 30 parts of butyl acetate in parts by weight.

[0043] 2. A preparation method for a high-transparency matte clear coating, comprising the following steps:

[0044] 1) Preparation of the main ingredient: mix alkyd resin, butyl acetate, modified silicon...

Embodiment 3

[0049] 1. A high-transparency matte clear finish coating, comprising a main agent, a curing agent and a diluent whose weight ratio is 1:0.8:1;

[0050] Among them, the main agent includes 65 parts by weight of alkyd resin, 1 part of butyl acetate, 3 parts of ethyl acetate, 1 part of nitrocellulose, 5 parts of organic matting powder, and 0.1 parts of modified silicone defoamer. 0.3 part of polymer dispersant, 1 part of polyamide wax and 0.1 part of organic leveling agent;

[0051] The diluent comprises 15 parts of xylene, 55 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate in parts by weight;

[0052] The curing agent includes 45 parts of aromatic isocyanate, 15 parts of trimer isocyanate and 20 parts of butyl acetate in parts by weight.

[0053] 2. A preparation method for a high-transparency matte clear coating, comprising the following steps:

[0054] 1) Preparation of the main ingredient: mix alkyd resin, butyl acetate, modified silicone defoame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com