A processing technology and a fixture for improving the production yield of pur reactive hot melt adhesive

A processing technology and hot-melt adhesive technology, applied in the field of viscose, can solve the problems of accelerated heat dissipation, hot and cold differences, and glue is prone to creep and pull, etc., and achieve the effect of improving the yield of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

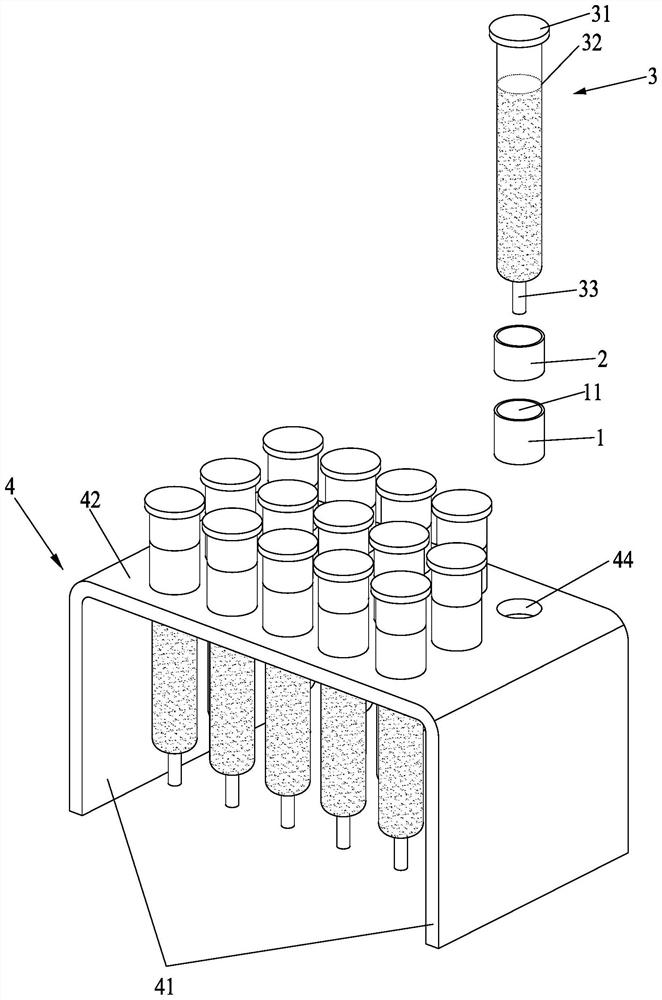

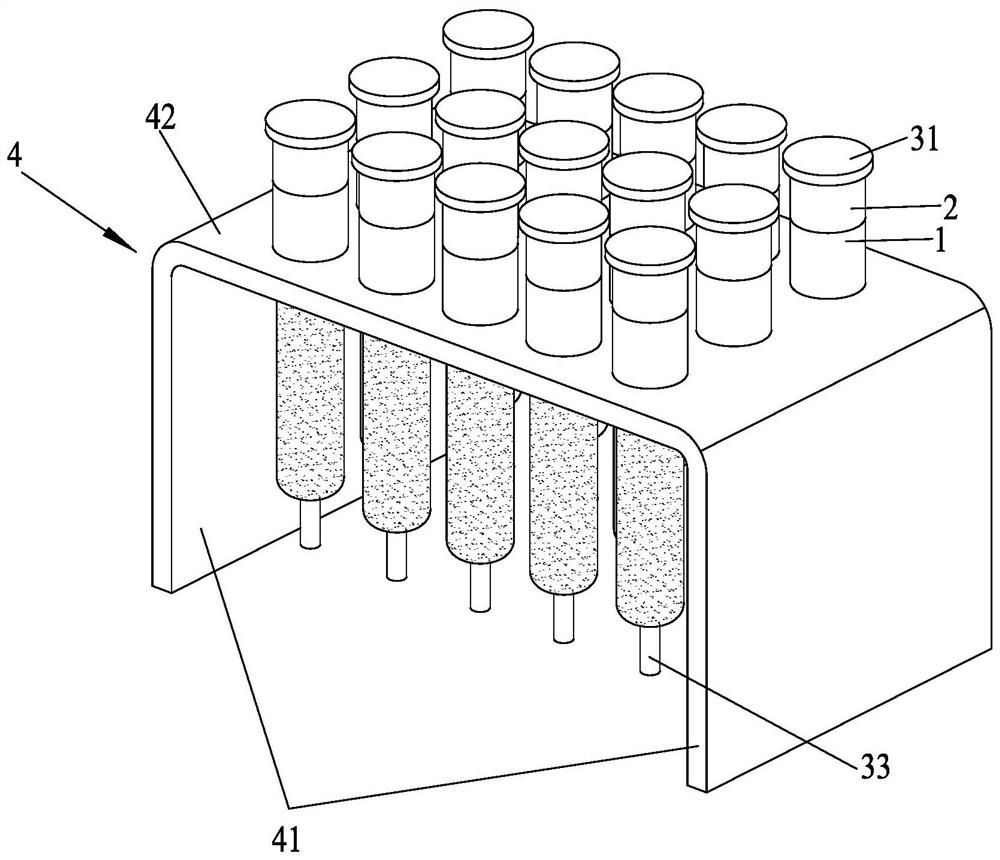

[0034] like figure 1 , 2 As shown, a jig for improving the production yield of PUR reactive hot melt adhesive includes a plurality of metal ferrules 1 with an initial temperature of W, a plurality of heat insulating gaskets 2, each isolation gasket 2 and each metal ferrule 1 When used with a rubber hose, the metal collar 1 is provided with a heating hole 11 penetrating up and down. The diameter of the heating hole 11 is slightly larger than the diameter of the rubber hose 3 to be heated. The longitudinal depth is 6cm; the center of the thermal insulation gasket 2 is hollowed out, and the thermal insulation gasket 2 is sleeved outside the rubber tube 3 and is located between the metal collar 1 and the sealing end cover 31 of the rubber tube 3 to isolate the metal collar 1 from the glue solution. Outside the rubber tube 3 at the surface 32, the upper end of the metal collar 1 is two centimeters higher than the glue liquid surface 32;

[0035] A support frame 4, the support fra...

Embodiment 2

[0046] like image 3 , 4 As shown, a fixture for improving the production yield of PUR reactive hot melt adhesive includes a heat source device and a positioning structure, the heat source device is an electric heating device with an initial temperature of W, specifically an electric heating plate 5, the The heating plate 5 is provided with a plurality of heating holes 11 penetrating up and down, the diameter of the heating holes 11 is slightly larger than the diameter of the hose 3 to be heated, and the longitudinal depth of the heating holes 11 is 6cm (that is, the thickness of the heating plate 5 is 6cm); The positioning structure includes two side fixing plates 6 and a positioning plate 7 that can move up and down along the two sides fixing plates 6; The plates 7 are arranged in parallel, and the positioning plate 7 is provided with a plurality of positioning holes 71. The positioning holes 71 have the same number as the heating holes 11 of the electric heating plate 5, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com