Preparation method and application of perovskite oxide catalyst containing alloy particles

A technology of perovskite oxide and alloy particles, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of easy agglomeration, low catalytic activity, and low electronic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

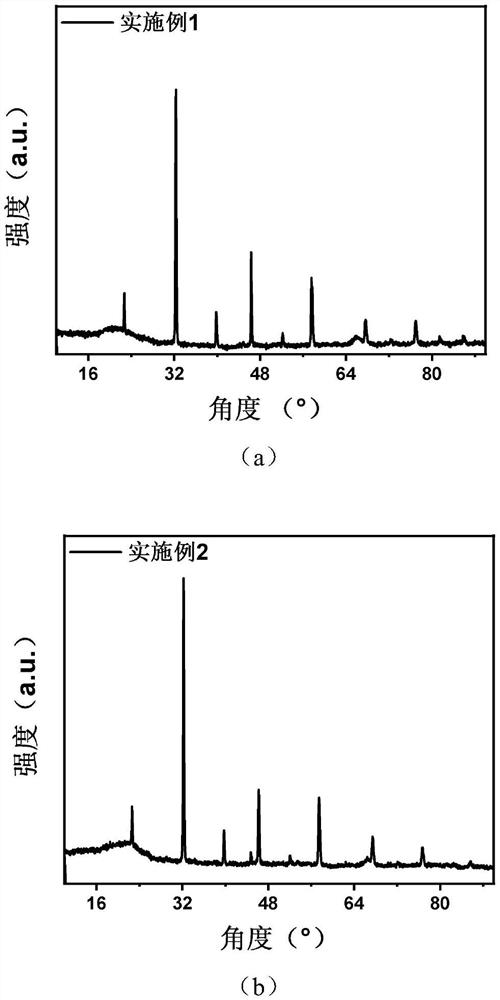

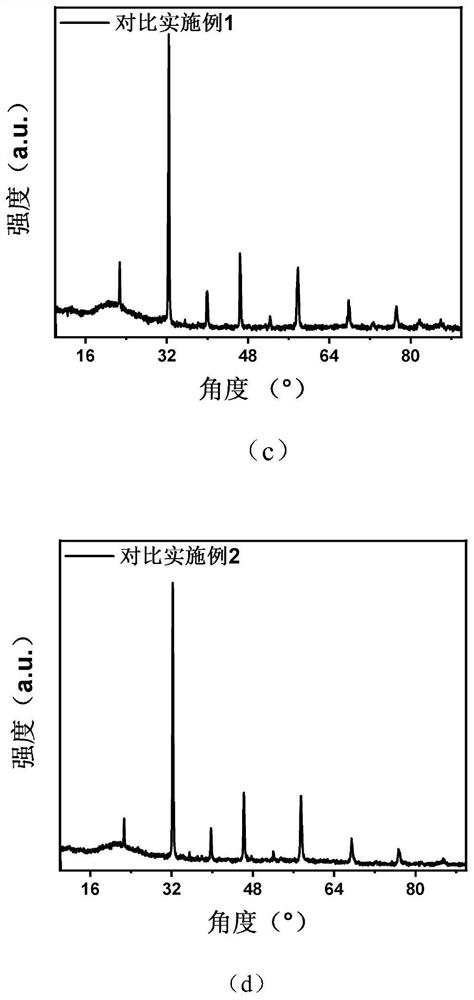

Embodiment 1

[0037] A preparation method of a perovskite oxide catalyst containing alloy particles, comprising the steps of:

[0038] S1. Add 0.0005mol of Co 2 O 3 , 0.0036mol La 2 O 3 , 0.0018mol SrCO 3 and 0.0045mol Fe 2 O 3 Mixed with 10ml of deionized water, and ball-milled at 300rpm for 5h in a ball-milling jar to obtain mixture A;

[0039] S2. The mixture A is calcined in a muffle furnace at 900° C. for 3 hours to obtain sample B;

[0040] S3. The sample B was calcined at 500° C. for 0.5 h in an atmosphere of a mixed gas of hydrogen and nitrogen (hydrogen: nitrogen = 5:95), so that part of the M alloy (CoFe) was changed from (La a Sr b ) x Fe 1-y-z Co y Ru z O3-δ precipitation, thereby obtaining a perovskite oxide catalyst containing alloy particles.

[0041] figure 2 (a) in the figure shows the scanning electron microscope picture of the alloy particle-containing perovskite oxide catalyst obtained in Example 1, which illustrates the analysis of the content of the pero...

Embodiment 2

[0043] A preparation method of a perovskite oxide catalyst containing alloy particles, comprising the steps of:

[0044] S1. Add 0.0005mol of Co 2 O 3 , 0.004mol La 2 O 3 , 0.002mol SrCO 3 , 0.004mol Fe 2 O 3 and 0.001mol RuO 2 Mixed with 15ml of deionized water, and ball-milled at 300rpm for 5h in a ball-milling jar to obtain mixture A;

[0045] S2. The mixture A is calcined in a muffle furnace at 1100° C. for 10 h to obtain sample B;

[0046] S3. The sample B was calcined at 900° C. for 5h in an atmosphere of a mixed gas of hydrogen and nitrogen (hydrogen:nitrogen=20:80), so that part of the M alloy (CoFe) was changed from (La a Sr b ) x Fe 1-y-z Co y Ru z O 3-δ precipitation, thereby obtaining a perovskite oxide catalyst containing alloy particles.

[0047] figure 2 Figure (b) in the figure shows a scanning electron microscope picture of the alloy particle-containing perovskite oxide catalyst obtained in Example 2, illustrating that the sample of Example 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com