Long-acting foam-stabilizing wall-mounted toilet cleaning block and preparation method thereof

A wall-mounted, toilet-cleaning block technology, applied in the field of daily chemicals, can solve the problems of insufficient foam stabilizing performance and acceptable foaming performance, and achieve the best long-term foam stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a long-acting foam-stabilizing wall-mounted toilet block, the formula of which is:

[0045] (1) Foaming agent: sodium dodecylbenzenesulfonate (LAS), sodium α-alkenylsulfonate (AOS);

[0046] (2) filler: sodium sulfate;

[0047] (3) Foam stabilizer: tea saponin, silicone resin polyether;

[0048] (4) Essence: lemon oil,

[0049] (5) Pigment: acid lake blue,

[0050] (6) Fungicide: p-chloro-m-xylenol,

[0051] (5) Wetting agent: water.

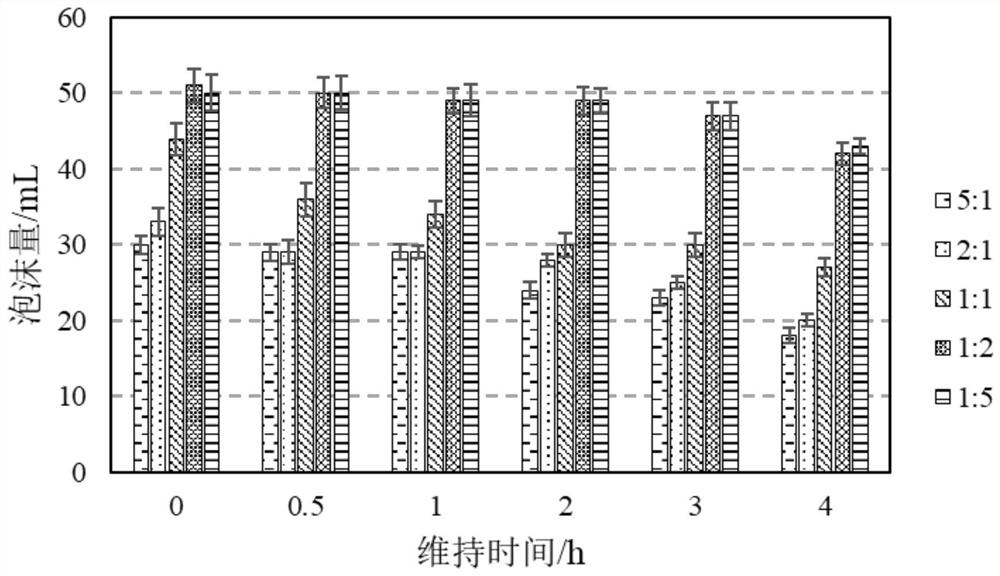

[0052] Among them, the combination and ratio optimization test of foaming agent is as follows:

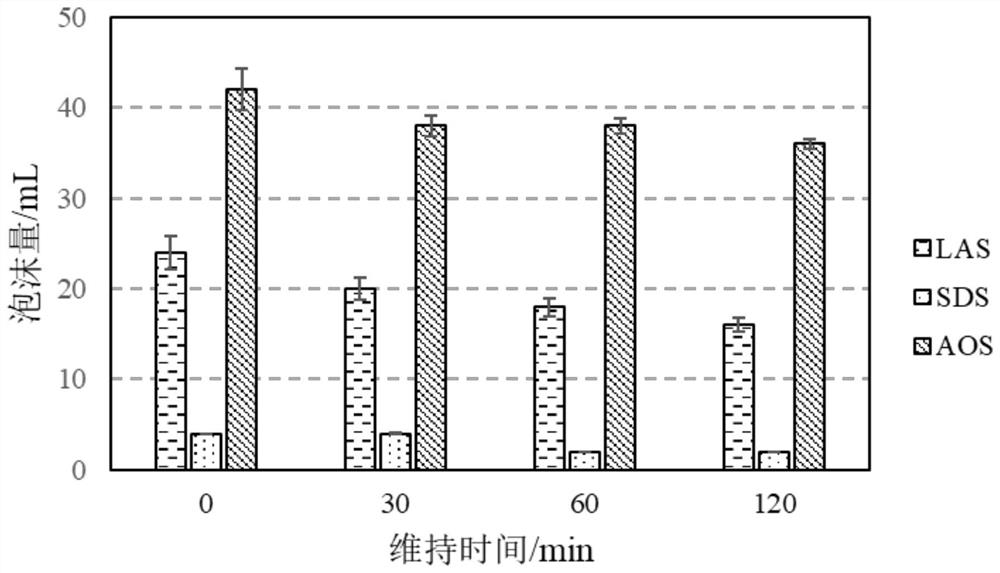

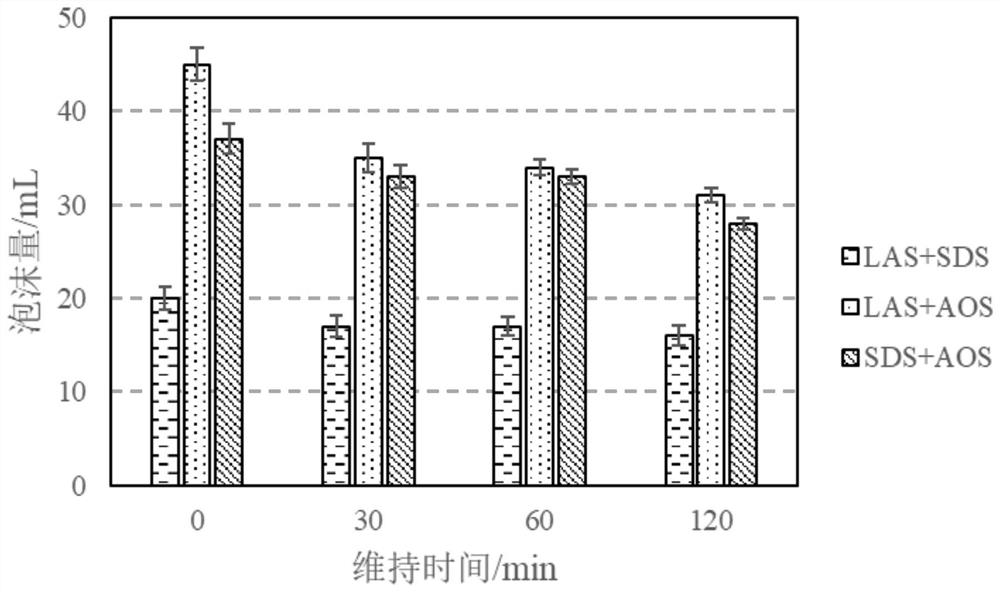

[0053] 1) The foaming ability and foam stabilizing ability of a single foaming agent

[0054] Control foaming agent concentration 0.05%, compare foaming agent: sodium dodecylbenzenesulfonate (LAS), sodium dodecylsulfate (SDS) and α-alkenylsulfonate sodium (AOS) foaming and stability Bubble ability;

[0055] The result is as figure 1 shown. It can be seen that AOS has the best foaming ability and foam stabiliz...

Embodiment 2

[0063] Consumption and combination optimization of foam stabilizer of the present invention:

[0064] (1) Optimization of dosage of silicone polyether (MPS)

[0065] Control foaming agent and foam stabilizer total concentration 0.05%, fix foaming agent mass ratio LAS:AOS=1:2, adjust foaming agent: MPS=50:1, 25:1, 20:1, 10:1, 5:1, compare the foaming and foam stabilizing ability of the combined composite system, the results are as follows Figure 4 shown.

[0066] It can be seen that adding MPS is helpful for foaming and foam stabilization, but it must be controlled between 20:1 and 10:1.

[0067] (2) Optimization of the dosage of tea saponin (TS)

[0068] Control foaming agent and foam stabilizer total concentration 0.05%, fix foaming agent mass ratio LAS:AOS=1:2, adjust foaming agent: TS=50:1, 25:1, 20:1, 10:1, 5:1, compare the foaming and foam stabilizing ability of the combined composite system, the results are as follows Figure 5 shown.

[0069] It can be seen that ...

Embodiment 3

[0074] (1) This embodiment provides a long-acting foam-stabilizing wall-mounted toilet block formula:

[0075] Sodium dodecylbenzene sulfonate, sodium alpha-olefin sulfonate, sodium sulfate, tea saponin, silicone polyether, lemon oil, acid lake blue, p-chloro-m-xylenol, and deionized water;

[0076] In terms of parts by mass, 28 parts of the sodium dodecylbenzenesulfonate, 56 parts of the sodium α-alkenylsulfonate, 8 parts of the sodium sulfate, 2.8 parts of the tea saponin, and the silicone resin polymer 1.4 parts of ether, 1 part of lemon oil, 1 part of acid lake blue, 0.1 part of p-chloro-m-xylenol, and 1.7 parts of deionized water.

[0077] (2) The preparation method of the wall-mounted toilet block of long-acting and stable foam:

[0078] Accurately weigh sodium dodecylbenzene sulfonate, sodium α-olefin sulfonate, sodium sulfate, tea saponin, acid lake blue and p-chloro-m-xylenol, and mix them in a powder mixer for 10 minutes;

[0079] Add water, silicone resin polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com