Antistatic plastic storage battery shell and production method thereof

A technology of antistatic plastics and battery shells, applied in the field of polymer materials, can solve problems such as low working temperature, large equipment wear, and easy generation of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

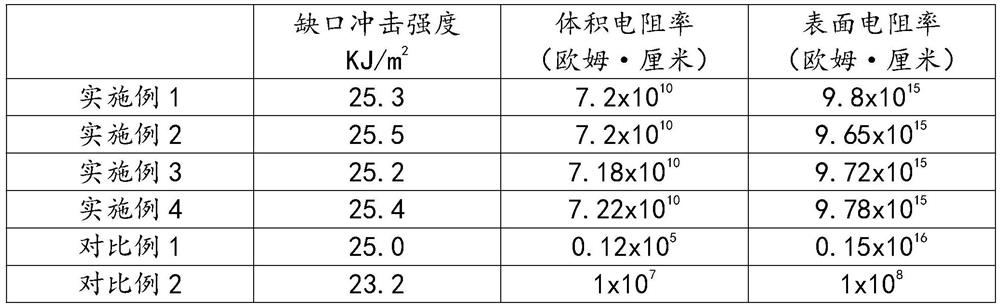

Examples

Embodiment 1

[0029] An antistatic plastic battery case, comprising the following raw materials in parts by weight: 10 parts of antistatic filler, 55 parts of matrix resin, 5 parts of carbon black, 5 parts of styrene-butadiene thermoplastic elastomer, 0.1 part of antioxidant 1010, 1 part of stearic acid Zinc;

[0030] The antistatic plastic battery shell is made by the following method:

[0031] The first step is to add the matrix resin and antistatic filler into the banbury mixer, control the banbury temperature to 150°C, the rotation speed to 50r / min, and the banbury time to 3min, then pulverize and dry at 70°C for 10h to produce get composite materials;

[0032] In the second step, add the composite material, carbon black, styrene-butadiene thermoplastic elastomer, antioxidant 1010 and zinc stearate into the mixing tank and stir evenly, then add it to the twin-screw extruder for extrusion, and control the extrusion temperature to 1 Zone 190°C, zone 2 220°C, zone 3 220°C, and then place...

Embodiment 2

[0043] An antistatic plastic battery case, comprising the following raw materials in parts by weight: 12 parts of antistatic filler, 60 parts of matrix resin, 6 parts of carbon black, 6 parts of styrene-butadiene thermoplastic elastomer, 0.3 part of antioxidant 1010, 1.2 parts of stearic acid Zinc;

[0044] The antistatic plastic battery shell is made by the following method:

[0045] The first step is to add the matrix resin and antistatic filler into the banbury mixer, control the banbury temperature to 150°C, the rotation speed to 50r / min, and the banbury time to 3min, then pulverize and dry at 70°C for 10h to produce get composite materials;

[0046] In the second step, add the composite material, carbon black, styrene-butadiene thermoplastic elastomer, antioxidant 1010 and zinc stearate into the mixing tank and stir evenly, then add it to the twin-screw extruder for extrusion, and control the extrusion temperature to 1 Zone 190°C, zone 2 220°C, zone 3 220°C, and then pl...

Embodiment 3

[0057] An antistatic plastic battery case, comprising the following raw materials in parts by weight: 14 parts of antistatic filler, 70 parts of matrix resin, 8 parts of carbon black, 8 parts of styrene-butadiene thermoplastic elastomer, 0.4 part of antioxidant 1010, 1.4 parts of stearic acid Zinc;

[0058] The antistatic plastic battery shell is made by the following method:

[0059] The first step is to add the matrix resin and antistatic filler into the banbury mixer, control the banbury temperature to 150°C, the rotation speed to 50r / min, and the banbury time to 3min, then pulverize and dry at 70°C for 10h to produce get composite materials;

[0060]In the second step, add the composite material, carbon black, styrene-butadiene thermoplastic elastomer, antioxidant 1010 and zinc stearate into the mixing tank and stir evenly, then add it to the twin-screw extruder for extrusion, and control the extrusion temperature to 1 Zone 190°C, zone 2 220°C, zone 3 220°C, and then pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com