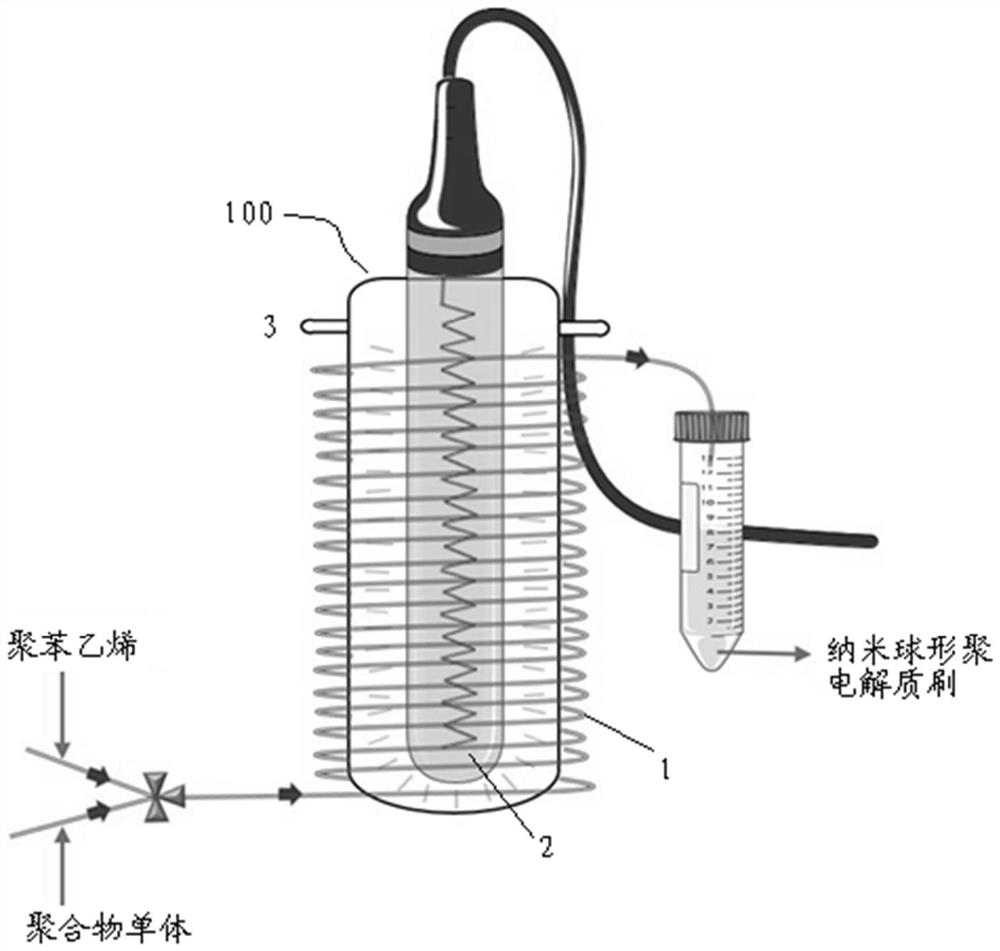

A kind of preparation method of nanometer spherical polyelectrolyte brush

A polyelectrolyte brush and spherical technology, which is applied in the field of preparation of nano-spherical polyelectrolyte brushes, can solve problems such as non-continuous production, and achieve the effects of continuous flow and preparation, simple method and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

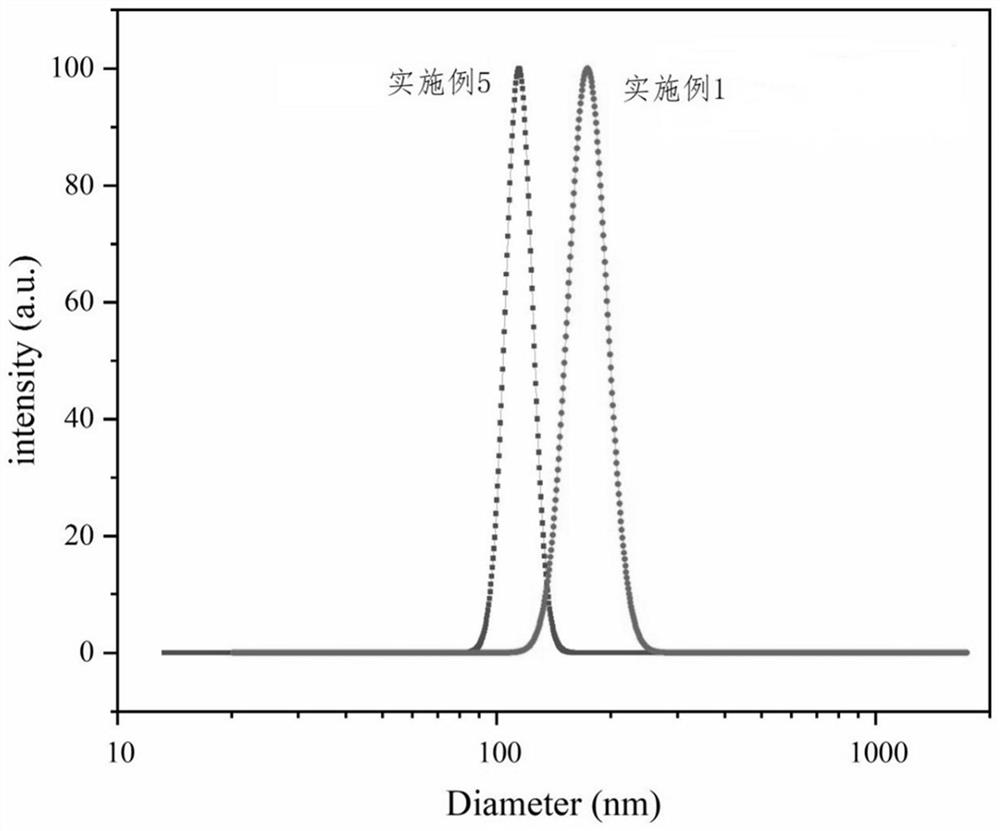

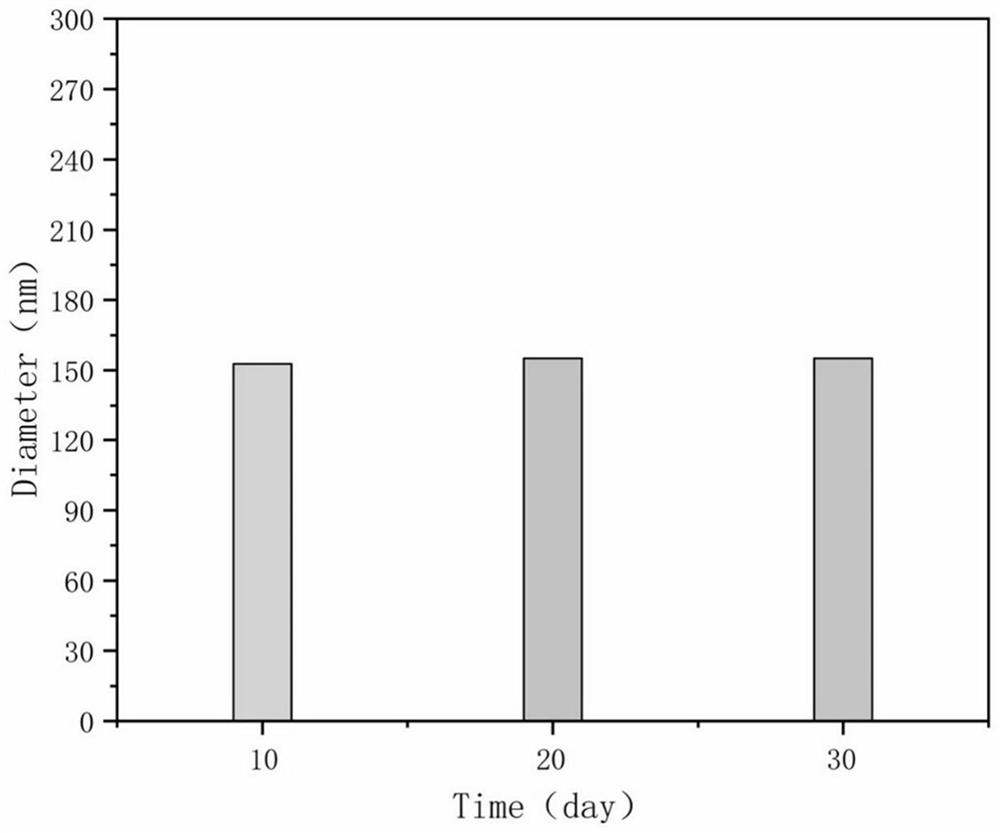

Embodiment 1

[0028] Take 20g of polystyrene core emulsion (the solid content is 3.5wt% and the particle size is 110nm) and deionized water is added to dilute to 1.7×10 -4 mol / mL, fill the 250mL four-necked flask with nitrogen 3 to 5 times, and draw out the 50mL syringe; 0.525g acrylic acid (75% of the solid content of the polystyrene core emulsion) is diluted with deionized water to 3.4×10 -4 mol / mL, fill the 250mL four-necked flask with nitrogen 3 to 5 times, draw out the 50mL syringe, and fix the syringe on the syringe pump; use a photomicroreactor with a microchannel size of 0.8mm and a volume of 3.165mL. 0.5mm T-shaped tee. The residence time is 1h, the two strands of materials are fed with a flow rate ratio of 1:1, and the products are collected at the outlet. After dialysis and purification in ultrapure water using a dialysis bag with a molecular weight cut-off of 14,000, the average particle size of the nano-spherical polyelectrolyte brush is measured as 180 nm (pH=8).

Embodiment 2

[0030] Take 20g of polystyrene core emulsion (the solid content is 3.5wt% and the particle size is 110nm) and deionized water is added to dilute to 1.369×10 -4 mol / mL, fill the 250mL four-necked flask with nitrogen for 3 to 5 times, and draw out the 50mL syringe; 0.49g of acrylic acid (70% of the solid content of the polystyrene core emulsion) is diluted with deionized water to 1.369×10 -4mol / mL, fill the 250mL four-necked flask with nitrogen for 3 to 5 times, draw out the 50mL syringe, and fix the syringe to the syringe pump; use a photomicroreactor with a microchannel size of 1.6mm and a volume of 18.689mL, and the inner hole of which is used for material mixing. 0.5mm T-shaped tee. The residence time is 1h, the two strands of materials are fed with a flow rate ratio of 1:1, and the products are collected at the outlet. After dialysis and purification in ultrapure water using a dialysis bag with a molecular weight cut-off of 14,000, the average particle size of the nano-sphe...

Embodiment 3

[0032] Take 20g of polystyrene core emulsion (the solid content is 3.5wt% and the particle size is 110nm) and deionized water is added to dilute to 1.369×10 -4 mol / mL, fill the 250mL four-necked flask with nitrogen for 3 to 5 times, and draw out the 50mL syringe; 0.21g of acrylic acid (30% of the solid content of the polystyrene core emulsion) is diluted with deionized water to 1.369×10 -4 mol / mL, fill the 250mL four-necked flask with nitrogen for 3 to 5 times, draw out the 50mL syringe, and fix the syringe to the syringe pump; use a photomicroreactor with a microchannel size of 1.6mm and a volume of 18.689mL, and the inner hole of which is used for material mixing. 0.5mm T-shaped tee. The residence time is 0.5h, the two materials are fed with a flow ratio of 1:1, and the products are collected at the outlet. After dialysis and purification in ultrapure water using a dialysis bag with a molecular weight cut-off of 14,000, the average particle size of the nano-spherical polyele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com