Steel slag micro-powder with weak retarding characteristic and production method thereof

A steel slag fine powder and production method technology, applied in cement production, chemical instruments and methods, climate sustainability, etc., can solve the problems of reduced steel slag utilization rate, difficult grinding, long cement or concrete retardation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

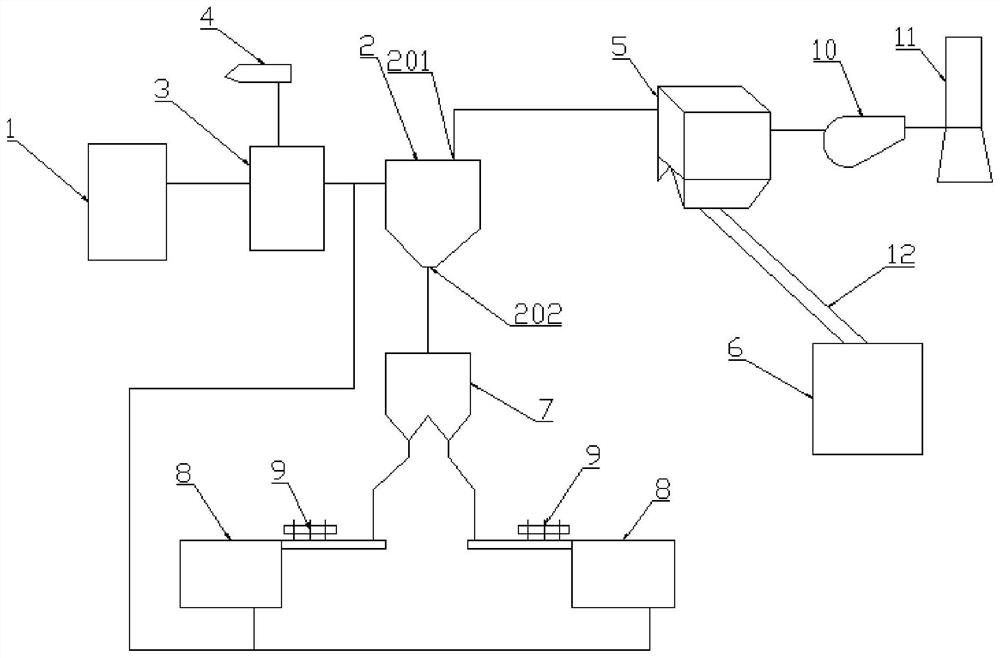

Method used

Image

Examples

Embodiment 1

[0041] A method for producing steel slag micropowder with weak retarding properties, the specific process is as follows:

[0042] The steel slag is transferred to the slag pool by a flatbed truck, and the steel slag is digested in the slag pool. The specific process is as follows:

[0043] The steel slag is cooled in a stepped cooling method, that is, the steel slag is cut into layers from the top to the bottom, and the cut layers are gradually cooled in turn, as follows:

[0044] (1) One time fetching water: 20m 3 / h water flow rate, water fetching 30min; water fetching is carried out with the basic principle of small flow rate and slow cooling, to avoid the instantaneous vaporization and expansion of water that is easy to occur when high-temperature steel slag is used for large-flow fetching water, causing the phenomenon of air blasting; Finally, the steel slag temperature is between 400-500°C;

[0045] (2) Second water fetching: 30m 3 / h pumping flow, pumping water for 6...

experiment example 1

[0066] Use the steel slag micropowder that embodiment 1 obtains to carry out following experiment:

[0067] 1. According to the ratio of benchmark cement:steel slag powder=70:30, measure the activity index of steel slag powder, the 3-day activity index is 56%, the 7-day activity index is 63%, and the 28-day activity index is 73%;

[0068] 2. According to cement clinker: limestone: gypsum: slag powder: steel slag powder = 58.8:5.6:5.6:15:15 to prepare composite cementitious material, initial setting is 163min, final setting is 245min; steam expansion rate is 0.19%; 1 day Compressive strength 9.3MPa, 3-day compressive strength 26MPa, 28-day compressive strength 47MPa;

[0069] 3. Prepare C30 concrete according to water: cement: steel slag powder: slag powder: sand: stone = 170:240:52:108:860:1005, the initial slump is 190mm, the 7-day compressive strength is 28MPa, and the 28-day compressive strength is 39MPa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com