Formula and method of ceramic wine bottle vanadium yellow matte decorative glaze

A ceramic wine bottle, vanadium yellow technology is applied in the field of vanadium yellow matte decorative glaze formulations for ceramic wine bottles, which can solve the problems of excessive heavy metals, low firing temperature, color fading, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Ceramic wine bottle vanadium yellow matte decorative glaze formulation, formulation including: potassium longite, quartz, square alumina, silica grayite, talc, alumina, zirconium silicate, kaolin, black material, vanadium yellow material, 镨 yellow material and Zirconium iron red, the mass content of each component is: 30 parts of potassium longite, 20 pieces of quartz, 5 serviles, 10 parts of silica amphitone, 15 talc, 5 parts of alumina, 5 parts of zirconium silicate, 10 parts of kaolin, 1 part of black material, 5 parts of vanadium yellow material, 3 pieces of yellow-yellowed materials and 1 zirconia red.

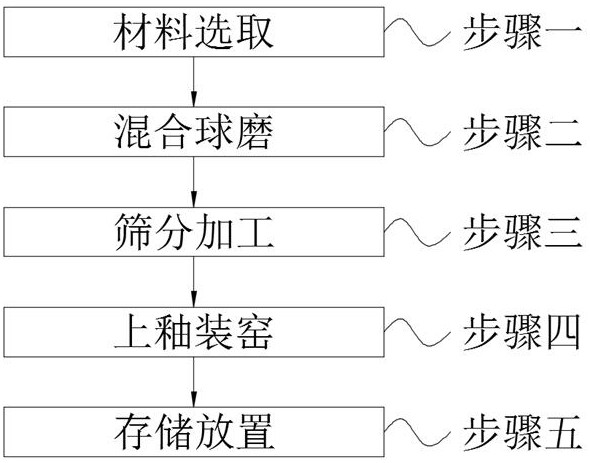

[0030]A method of ceramic wine bottle vanadium yellow matte decorative glaze formulation, including step one, material selection; step two, mix ball mill; step three, screen processing; step four, glaze the kiln; Step 5, storage place;

[0031]In the above steps, in the above steps, the contents of each component are: 30 parts of potassium waith, 20 parts of quartz, 5 parts of ...

Embodiment 2

[0043]Ceramic wine bottle vanadium yellow matte decorative glaze formulation, formulation including: potassium longite, quartz, square alumina, silica grayite, talc, alumina, zirconium silicate, kaolin, black material, vanadium yellow material, 镨 yellow material and Zirconium iron red, the mass content of each component is: 35 pieces of potassium waith, 15 pieces of quartz, 5 square solutions, 10 parts of silica amphitone, 15 talc, 5 parts of alumina, 5 parts of zirconium silicate, 10 parts of kaolin, 1 part of black material, 5 parts of vanadium yellow material, 3 pieces of yellow-yellowed materials and 1 zirconia red.

[0044]A method of ceramic wine bottle vanadium yellow matte decorative glaze formulation, including step one, material selection; step two, mix ball mill; step three, screen processing; step four, glaze the kiln; Step 5, storage place;

[0045]In the above steps, in accordance with the contents of the components, the contents of each component are: 35 parts of potassium ...

Embodiment 3

[0057]Ceramic wine bottle vanadium yellow matte decorative glaze formulation, formulation including: potassium longite, quartz, square alumina, silica grayite, talc, alumina, zirconium silicate, kaolin, black material, vanadium yellow material, 镨 yellow material and Zirconium iron red, the mass content of each component is: 40 parts of potassium longshite, 10 parts of quartz, 5 partial flu solution, 10 parts of silica amphitite, 15 talc, 5 parts of alumina, 5 parts of zirconium silicate, 10 parts of kaolin, 1 part of black material, 5 parts of vanadium yellow material, 3 pieces of yellow-yellowed materials and 1 zirconia red.

[0058]A method of ceramic wine bottle vanadium yellow matte decorative glaze formulation, including step one, material selection; step two, mix ball mill; step three, screen processing; step four, glaze the kiln; Step 5, storage place;

[0059]In the above steps, in accordance with the contents of each component, 40 parts of potassium waith, 10 parts of quartz, 5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com