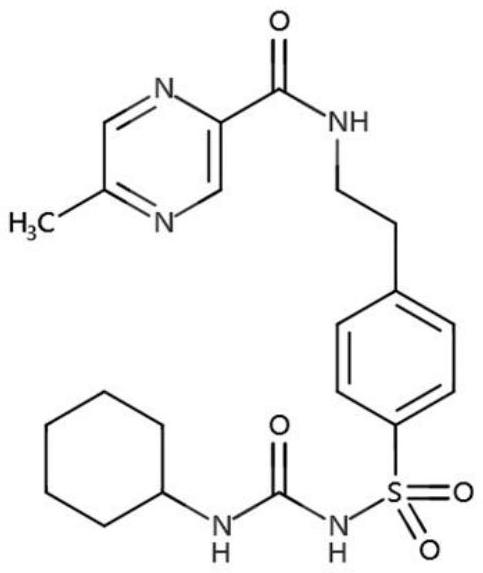

Glipizide controlled release tablet and preparation method thereof

A technology of glipizide and controlled-release tablets, which is applied in pharmaceutical formulations, medical preparations of non-active ingredients, drug delivery, etc., can solve the problems of laser intensity attenuation, unstable quality, and high manufacturing costs, and achieve improved solubility , meet the needs of drug administration, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

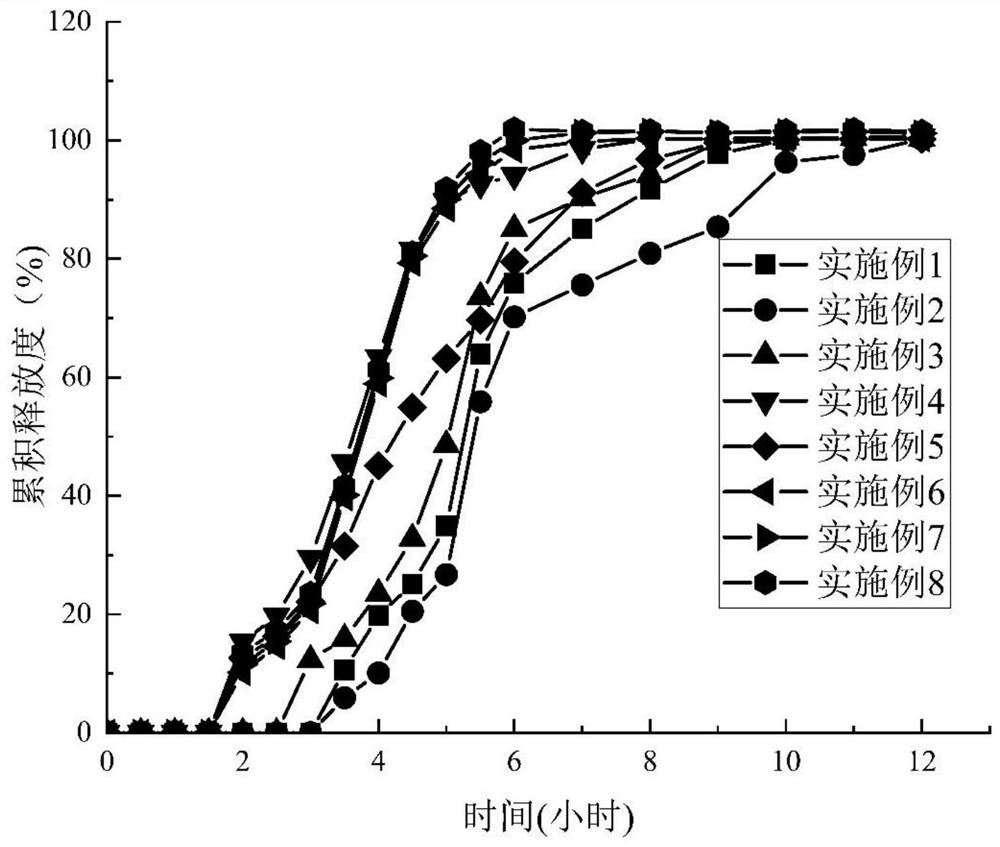

Examples

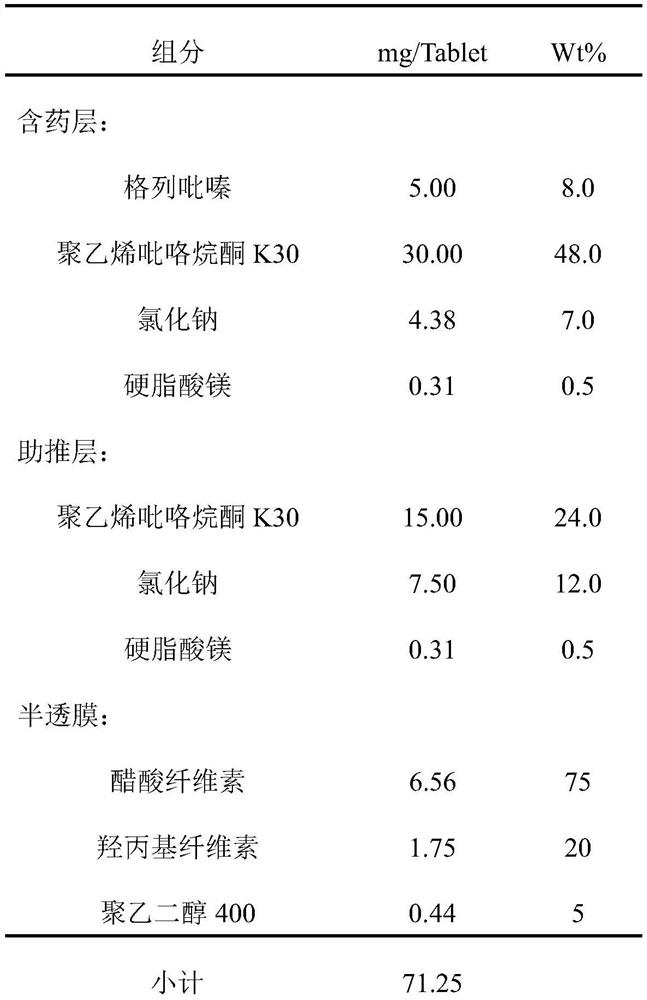

Embodiment 1

[0054] A kind of preparation method of glipizide controlled-release tablet in the present embodiment comprises the following steps:

[0055] 1) Drug-containing layer

[0056] Put the prescribed amount of polyvinylpyrrolidone K30 and the prescribed amount of glipizide into a low-shear V-type mixer for mixing, mix for 30 minutes to obtain a mixed powder, and then prepare the mixed powder by hot-melt extrusion to prepare a solid dispersion. Crush, sieve, the particle size range is 75-250μm, add the prescribed amount of sodium chloride and magnesium stearate to the prescribed amount of solid dispersion powder, mix in a low-shear V-type mixer, and mix for 30min. The mixed powder of the drug-containing layer is obtained.

[0057] 2) booster layer

[0058] Put the prescribed amount of polyvinylpyrrolidone K30 and sodium chloride into a low-shear V-shaped mixer for mixing, mix for 30 minutes, add the prescribed amount of magnesium stearate, and then mix in a low-shear V-shaped mixer...

Embodiment 2

[0066] A kind of preparation method of glipizide controlled-release tablet in the present embodiment comprises the following steps:

[0067] 1) Drug-containing layer

[0068] Put the prescribed amount of polyvinylpyrrolidone K30 and the prescribed amount of glipizide into a low-shear V-type mixer for mixing, mix for 30 minutes to obtain a mixed powder, and then prepare the mixed powder by hot-melt extrusion to prepare a solid dispersion. Crush, sieve, the particle size range is 75-250μm, add the prescribed amount of hypromellose, sodium chloride and magnesium stearate to the prescribed amount of solid dispersion powder, in a low-shear V-type mixer Mixed for 30 minutes to obtain the mixed powder of the drug-containing layer.

[0069] 2) booster layer

[0070] Put the prescribed amount of polyvinylpyrrolidone K30 and sodium chloride into a low-shear V-shaped mixer for mixing, mix for 30 minutes, add the prescribed amount of magnesium stearate, and then mix in a low-shear V-sha...

Embodiment 3

[0079] A kind of preparation method of glipizide controlled-release tablet in the present embodiment comprises the following steps:

[0080] 1) Drug-containing layer

[0081] Put the prescribed amount of polyvinylpyrrolidone K30 and the prescribed amount of glipizide into a low-shear V-type mixer for mixing, mix for 30 minutes to obtain a mixed powder, and then prepare the mixed powder by hot-melt extrusion to prepare a solid dispersion. Crush, sieve, the particle size range is 75-250μm, add the prescribed amount of hypromellose, sodium chloride and magnesium stearate to the prescribed amount of solid dispersion powder, in a low-shear V-type mixer Mixed for 30 minutes to obtain the mixed powder of the drug-containing layer.

[0082] 2) booster layer

[0083] Put the prescribed amount of polyvinylpyrrolidone K30 and sodium chloride into a low-shear V-shaped mixer for mixing, mix for 30 minutes, add the prescribed amount of magnesium stearate, and then mix in a low-shear V-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com