Tree planting slurry and tree planting method

A slurry and tree pit technology, which is applied in the agricultural field, can solve the problems of high cost and high energy consumption, and achieve the effect of reducing the storage area and secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparations before the implementation of the present invention:

[0050] (A) Prepare raw materials:

[0051] Prepare 860 kg of fly ash with a particle size of not more than 3.0 mm, and crush it with fresh willow branches to make 140 kg of debris with a particle size of not more than 3.0 mm. Stir 860 kg of the above-mentioned fly ash and salix twig debris with 450 kg of flue gas purification waste liquid (mainly containing ammonium salt solution of sulfurous acid and nitrous acid) in a stirring container to make a tree planting slurry A;

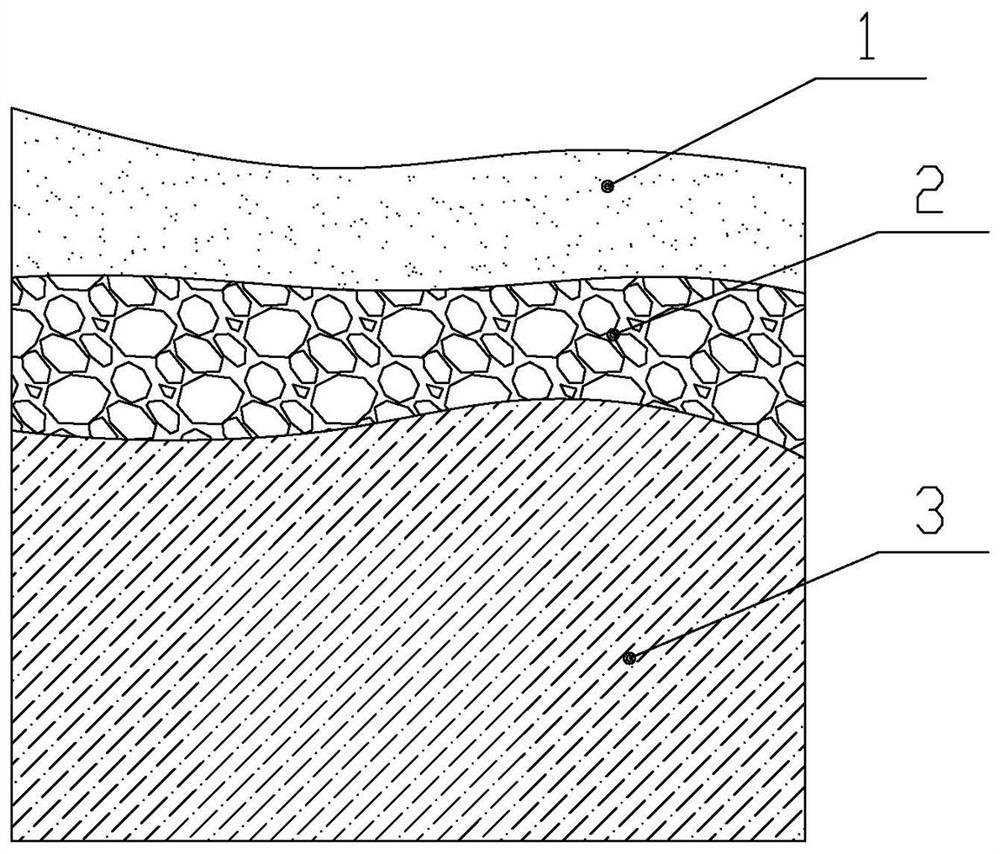

[0052] (B) Prospecting and surveying the tree planting area to judge the soil structure ( figure 1 ):

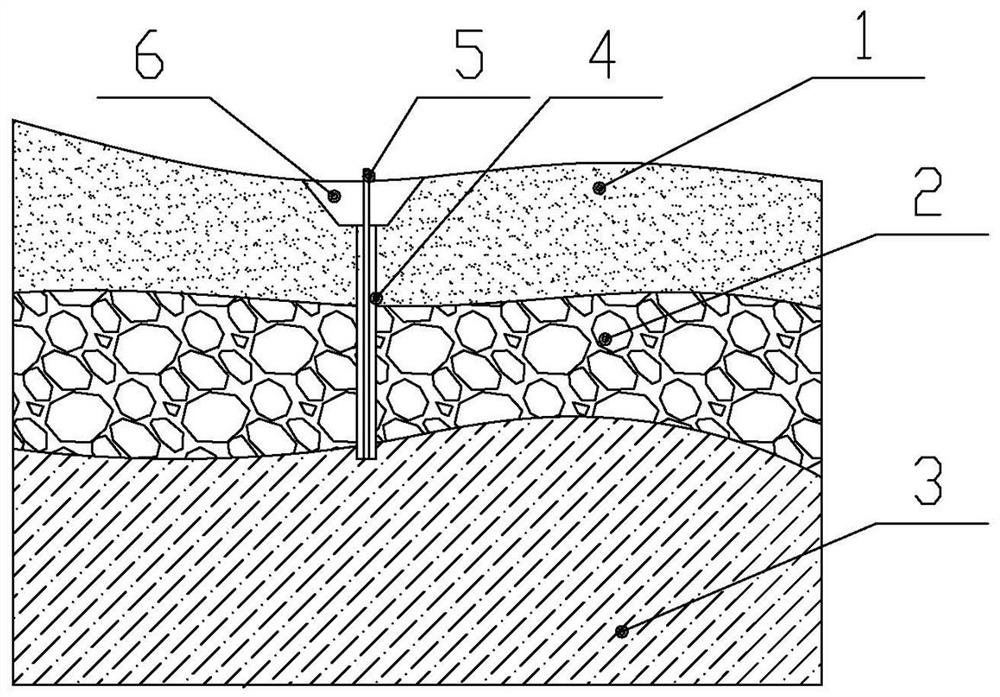

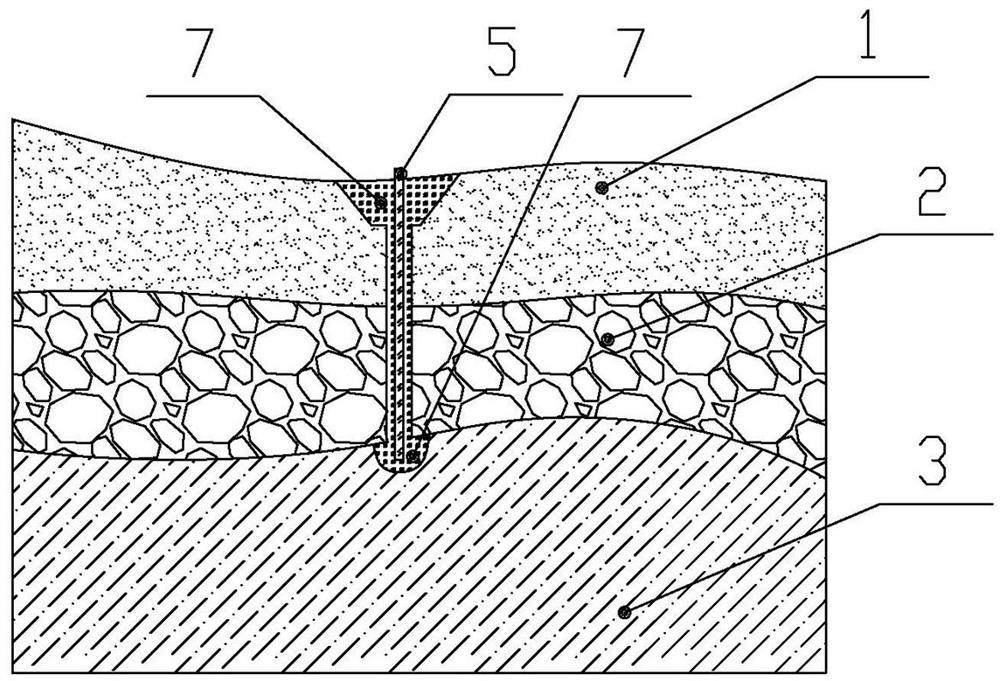

[0053] Measure the thickness of the ground soil layer of the embodiment (a sandy land in northern China), the thickness of the calcareous soil, estimate the depth of the grouting hole, and the insertion depth of the grouting pipe ( figure 1 , figure 2 , image 3 ), etc., determine the amount of grouting and the working parame...

Embodiment 2

[0065] Operating parameters and material preparation:

[0066] Prepare 855 kg of fly ash with a particle size not greater than 3.0 mm, and crush them with crop straw to make 145 kg of debris with a particle size not larger than 3.0 mm. Stir 855 kg of fly ash, 145 kg of crop straw debris and 450 kg of flue gas purification waste liquid (mainly containing ammonium salt solution of sulfurous acid and nitrous acid) in a stirring container to make tree planting slurry B.

[0067] Prospecting and surveying the tree-planting area (a grassland in northern China) to determine the soil structure ( figure 1 ), measure the thickness of the ground soil layer, the thickness of the calcium layer soil, estimate the depth of the grouting hole, and the insertion depth of the grouting pipe ( Figure 4 ), etc., determine the amount of grouting and the working parameters of the grouting machine, etc.; finally determine the size of each tree-planting barrel tree pit and the depth of the grouting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com