Low-pressure annealing method for crystalline silicon solar cell

A solar cell, low-voltage technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of unstable gas flow in the tube, restricting the development of battery technology, unfavorable silicon oxide layer growth, etc. Effect of anti-PID performance, short-circuit current and open-circuit voltage improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

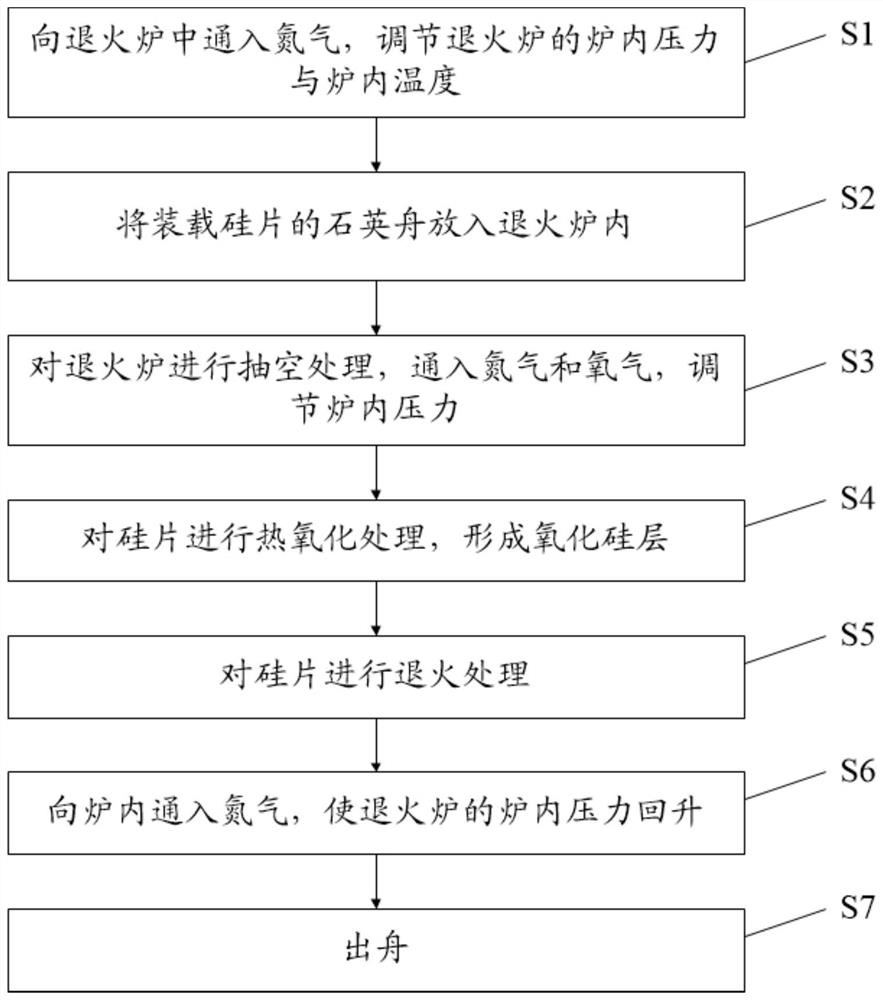

[0088] Example 1 group is a low-pressure annealing method for crystalline silicon solar cells with different pressures in the furnace after evacuation treatment, including:

[0089] (1) feed nitrogen into the annealing furnace to adjust the pressure and temperature in the furnace of the annealing furnace;

[0090] (2) Put the quartz boat loaded with silicon wafers into the annealing furnace;

[0091] (3) Evacuate the annealing furnace, feed nitrogen and oxygen, and adjust the pressure in the furnace;

[0092] (4) Carry out thermal oxidation treatment to silicon chip, form silicon oxide layer;

[0093] (5) Carry out annealing treatment to silicon chip;

[0094] (6) feed nitrogen into the furnace to make the furnace pressure of the annealing furnace rise;

[0095] (7) out of the boat;

[0096] Wherein, the pressure in the furnace of step (3)(4)(5) is maintained at 100-300mbar.

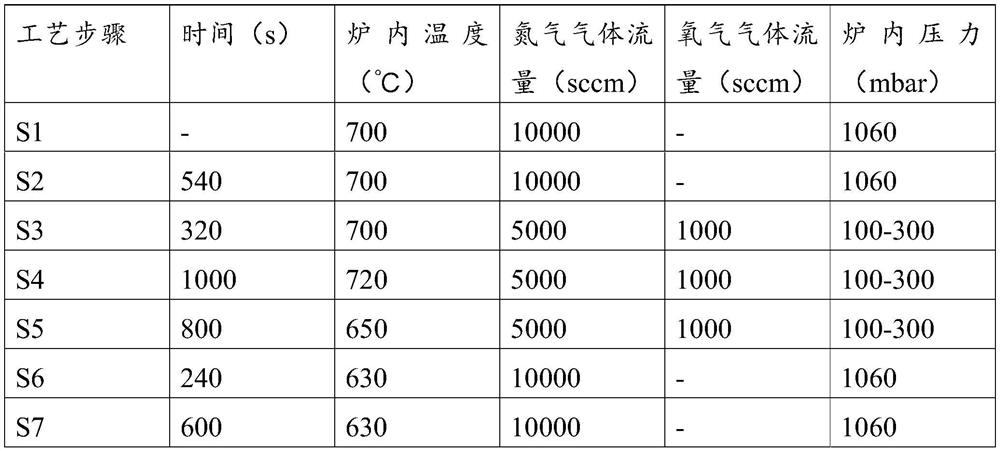

[0097] The technical parameters in the embodiment 1 group are specifically referred to in Table 1:...

Embodiment 1-1

[0101] Embodiment 1-1: the pressure in the furnace is 100mbar;

Embodiment 1-2

[0102] Embodiment 1-2: the pressure in the furnace is 200mbar;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com