Rolling bearing intelligent fault diagnosis method based on vibration signals

A rolling bearing and fault diagnosis technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of dispersion, small data sample database, missing key information, etc., and achieve easy precision, increased dimensionality, and coverage The effect of a wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

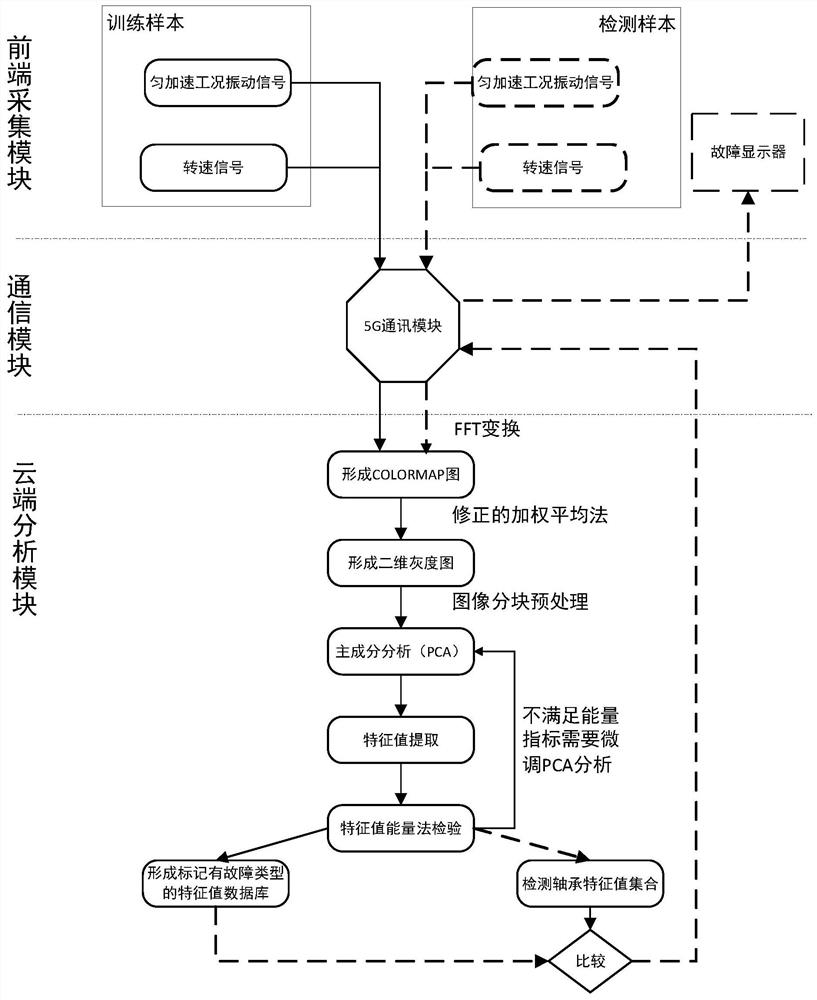

[0053] An intelligent fault diagnosis method for rolling bearings based on vibration signals, referring to figure 1 shown, including:

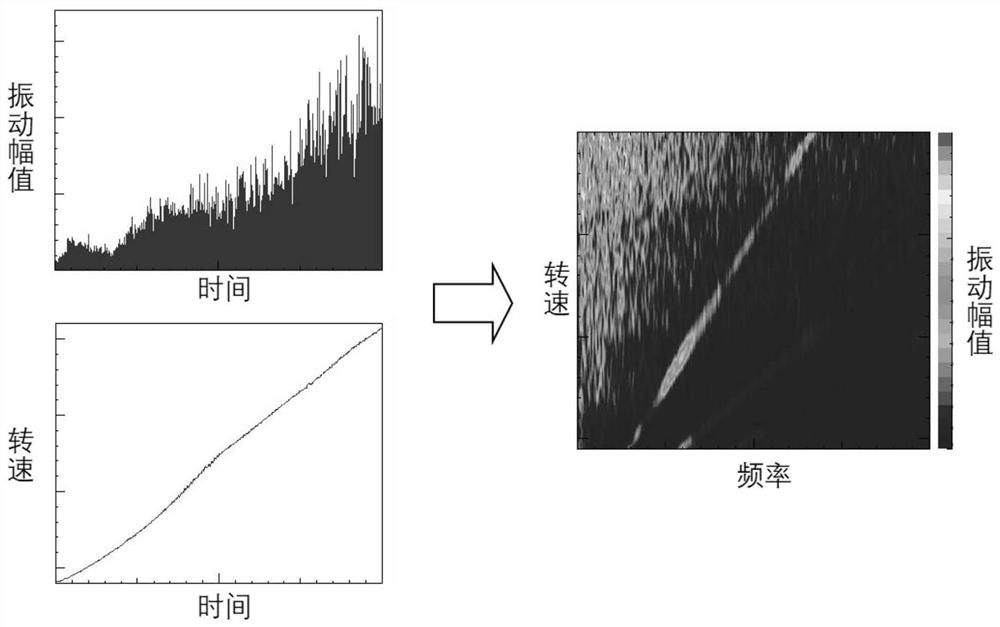

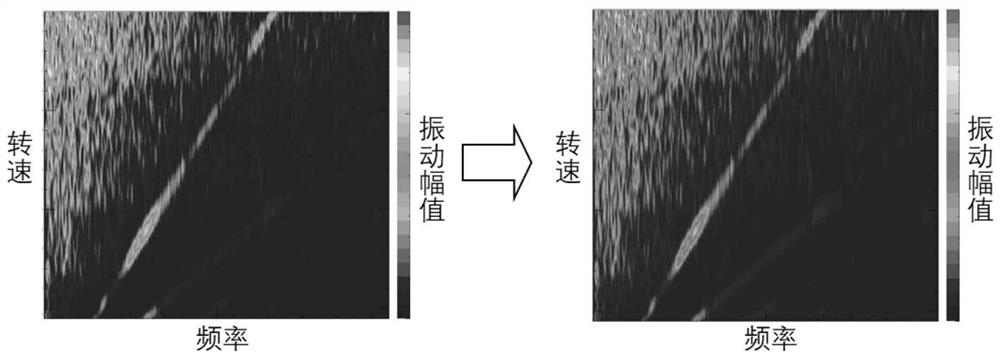

[0054] Step 1. Collect the three-way vibration acceleration signal and speed signal of the rolling bearing to be tested through the front-end acquisition module. The slow acceleration working condition is set according to the type of the rolling bearing to be tested and the information of the application equipment, and the rolling bearing to be tested is slowly accelerated from zero speed to the maximum speed. The speed, vibration time domain signal and speed time domain signal are preprocessed, sampled, quantized, and coded to realize data collection. The vibration signal adopts the uniform acceleration condition from zero to the highest spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com