Multi-marker liquid chip and preparation method thereof

A solution and compound technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of reducing the content of target substances, unstable uniformity of microsphere functional groups, reducing the reactivity of activating groups, etc., and achieves easy operation , Prevent aggregation and adhesion, and the effect of small sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example provides a method for preparing a primary antibody-microsphere complex:

[0047] 1. Primary antibody desalting treatment

[0048] S11: Use PBS buffer to wash the desalting column, centrifuge at 1500g for 1 min, remove the buffer, and repeat the washing operation twice;

[0049] S12: Add the primary antibody and centrifuge at 1500g for 2 minutes to obtain the desalted primary antibody.

[0050] 2. Microsphere activation treatment

[0051] S21: Take 2 mg of microspheres, use MES buffer for gradient washing, fully mix with a vortex mixer, separate and remove the supernatant, and repeat the washing step twice to obtain microspheres after washing;

[0052] S22: Mix 38 μL NHS and 19 μL EDC with the washed microspheres, and rotate them in a vortex mixer for 1 hour to obtain activated microspheres to be cleaned; the concentration of NHS and EDC is 50 mg / ml;

[0053] S23: Using the ligation buffer to wash the activated microspheres to be washed three times repeat...

Embodiment 2

[0061] This embodiment provides a method for preparing a multiple marker liquid chip:

[0062] 1. The primary antibody-microsphere complex was prepared by the preparation method provided in Example 1.

[0063] 2. Secondary Antibody Desalting Treatment

[0064] S41: wash the desalting column with PBS buffer, centrifuge at 1500g for 1 min, remove the buffer, and repeat the washing operation twice;

[0065] S42: Add secondary antibody, centrifuge at 1500 g for 2 min to obtain desalted secondary antibody.

[0066] 3. Cross-linking of Desalted Secondary Antibody with Biotin

[0067] S51: dissolving 5 mg of NHS-biotin in 100 μL of DMSO to obtain an NHS-biotin solution;

[0068] S52: Take 15 μL of NHS-biotin solution and 780 ug of desalted secondary antibody for 5 hours at room temperature and shake in the dark to obtain a secondary antibody-biotin complex.

[0069] In the preparation method provided by Example 1 and Example 2, MES buffer solution and ligation buffer were used fo...

Embodiment 3

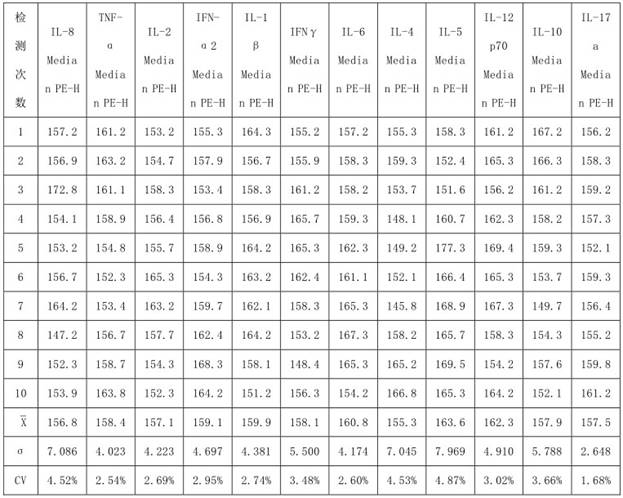

[0071] This embodiment provides a multiple marker liquid chip prepared by the method provided in Example 2.

[0072] Using the liquid chip provided in this example to carry out intra-batch and inter-batch experiments, the steps are as follows:

[0073] 1. Take the primary antibody-microsphere complex out of the refrigerator, return to room temperature, vortex to mix, and pipette 20 μL into 96-well plate.

[0074] 2. Add 10 μL of clinical serum sample and 50 μL of diluent to each well. Shake and react at room temperature for 2 hours in the dark.

[0075] 3. Add 200 μL of washing solution to each well, shake for 30 seconds, magnetically adsorb for 1 minute, and absorb the supernatant.

[0076] 4. Add 50 μL of secondary antibody-biotin complex to each well. Shake and react at room temperature for 2 hours in the dark.

[0077] 5. Add 50 μL of PE-SA, shake and react at room temperature for 30 minutes in the dark.

[0078] 6. Add 200 μL of washing solution to each well, shake f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com