Novel optical fiber temperature measurement system of transformer station high-voltage switch cabinet

A high-voltage switchgear, optical fiber temperature measurement technology, applied in substation/switch layout details, substation/switchgear board/panel/desk, substation/power distribution device shell, etc., can solve the contact operating temperature in high-voltage switchgear Difficult to monitor, heating of components, difficult to measure and other problems, achieve simple and reliable alarm mode, anti-electromagnetic interference, and solve the effects of difficult monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

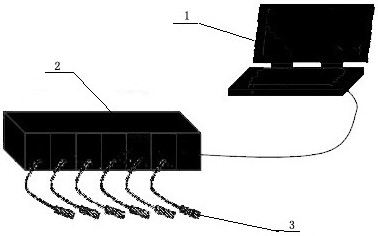

[0034] Such as figure 1 Shown is a schematic structural diagram of a new type of optical fiber temperature measurement system for a substation high-voltage switchgear provided by the present invention, including a lower computer and six optical fiber method-percent sensors connected to it through six channels. The lower computer communicates through USB Connect with the host computer; the host computer completes data communication, multi-channel data decoding, real-time display of multi-channel data, saves data and subsequent processing work; the lower computer completes multi-channel optical fiber method-Person sensing signal acquisition , processing, demodulation and complete communication with the host computer.

[0035] The main function of the upper computer is to complete the data display and subsequent processing. Using a PC, it sends control commands to the lower computer through USB communication, completes data communication, multi-channel data decoding, real-time di...

Embodiment 2

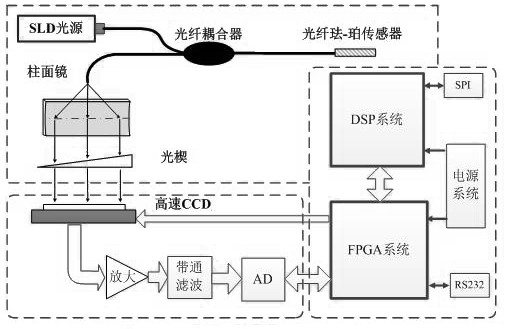

[0046] According to the design of the temperature measurement system provided by this application, six channels are used, and the multi-channel is a parallel structure, so each channel needs a demodulation module structure. The demodulation module structure is the core optical module of each channel, and the optical fiber is completed for each channel. The F-P non-scanning correlation operation is used to obtain the correlation signal between the fiber F-P sensor and the optical wedge.

[0047] The light source is divided into six paths to reach the sensor through a 3×6 fiber optic coupler, and the light carrying sensor information enters the demodulation optical path of each module. The difference between this embodiment and the embodiment is that the demodulation module includes a cylindrical mirror, Optical wedges, photodetectors, and optical wedges are the key optical devices for demodulating and realizing correlation operations to obtain related signals, and their quality ...

Embodiment 3

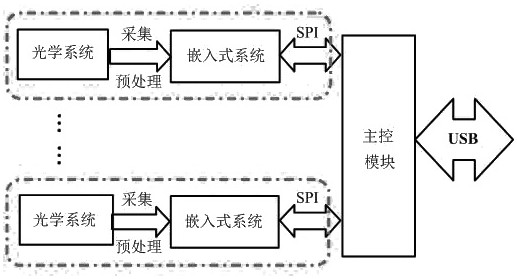

[0053] According to the system structure diagram and the functions of each part, the hardware system design of this system is mainly the design of the hardware system of the lower computer. The lower computer is further divided into: six-channel optical fiber method - Perco sensor acquisition and demodulation module and the main control module. The main function of the optical fiber method-Pertinent sensing acquisition and demodulation module is to complete the acquisition, processing and demodulation of the optical fiber method-Pertinent non-scanning related demodulation signal after receiving the instruction, and send the demodulation result to the main control module. The main control module is responsible for communicating with the upper computer, receiving and interpreting instructions, controlling each channel to start working in a specific mode, and sending the demodulation results of each acquisition and demodulation module to the upper computer.

[0054] The embedded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com