A field-assembled distribution transformer gear live detection device

A distribution transformer and field assembly technology, applied in the field of distribution network, can solve the problems of inflexible structure, inconvenient operation, inconvenient portability, etc., and achieve the effect of solving inflexible structure, ensuring convenience and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

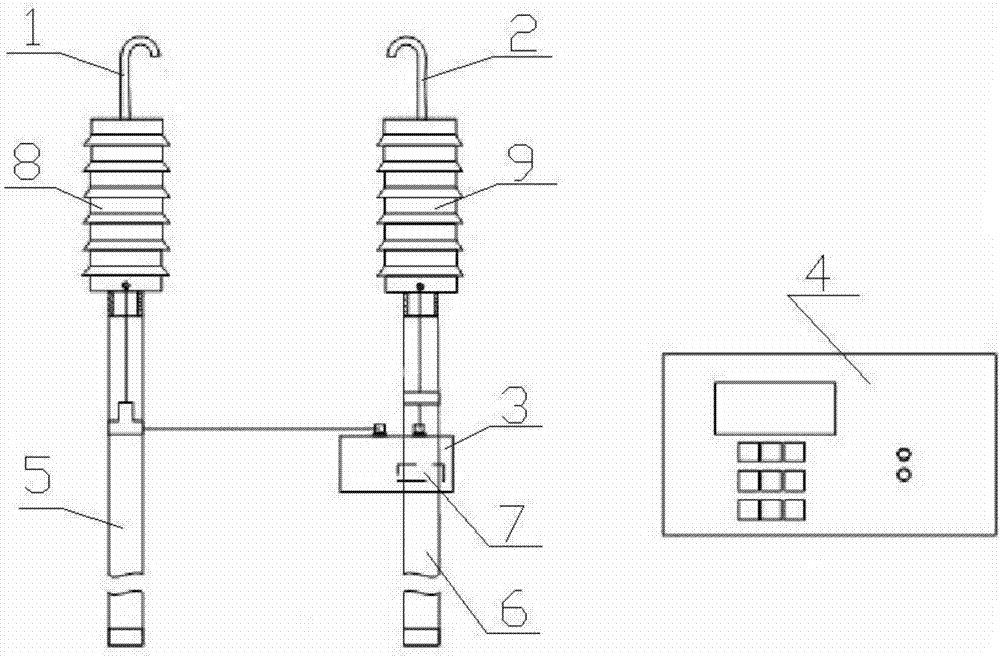

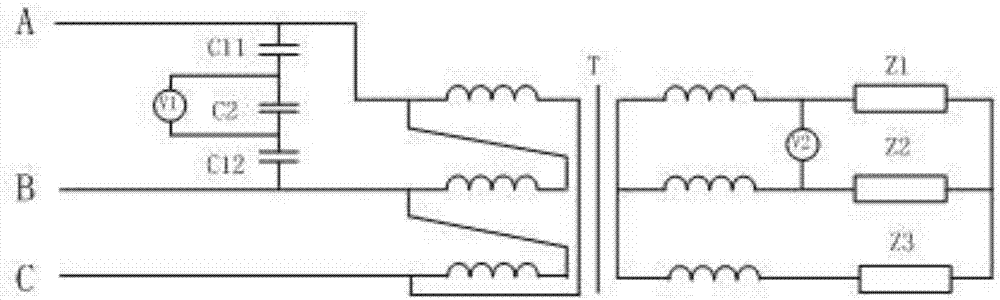

[0019] Such as figure 1 As shown, the embodiment of the present invention provides a field-assembled distribution transformer gear live detection device, the detection device includes a measuring electrode, a high-voltage arm capacitance and a ring rod, and the measuring electrode includes a first measuring electrode 1 and a The second measuring electrode 2, the high-voltage arm capacitance includes a first high-voltage arm capacitance 8 and a second high-voltage arm capacitance 9, and the order rod includes a first order rod 5 and a second order rod 6, and the first order bar The measuring electrode 1 is connected to the first high-voltage arm capacitor 8, the second measuring electrode 2 is connected to the second high-voltage arm capacitor 9, and the first high-voltage arm capacitor 8 is connected to the first rod 5. The second high-voltage arm capacitor 9 is connected to the second gram bar 6, the first gram bar 5 or the second gram bar 6 is provided with a high-voltage me...

Embodiment 2

[0022] Such as figure 1 As shown, the embodiment of the present invention provides a field-assembled distribution transformer gear live detection device, the detection device includes a measuring electrode, a high-voltage arm capacitance and a ring rod, and the measuring electrode includes a first measuring electrode 1 and a The second measuring electrode 2, the high-voltage arm capacitance includes a first high-voltage arm capacitance 8 and a second high-voltage arm capacitance 9, and the order rod includes a first order rod 5 and a second order rod 6, and the first order bar The measuring electrode 1 is connected to the first high-voltage arm capacitor 8, the second measuring electrode 2 is connected to the second high-voltage arm capacitor 9, and the first high-voltage arm capacitor 8 is connected to the first rod 5. The second high-voltage arm capacitor 9 is connected to the second gram bar 6, the first gram bar 5 or the second gram bar 6 is provided with a high-voltage me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com