Single-component dealcoholized silicone sealant and preparation method thereof

A technology of alcohol silicone and sealant, which is applied in the field of one-component dealcohol silicone sealant and its preparation, can solve the problems of incompatibility between deep curing speed and physical and mechanical properties, and achieve excellent physical and mechanical properties and physical and mechanical properties Good, the effect of increasing the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

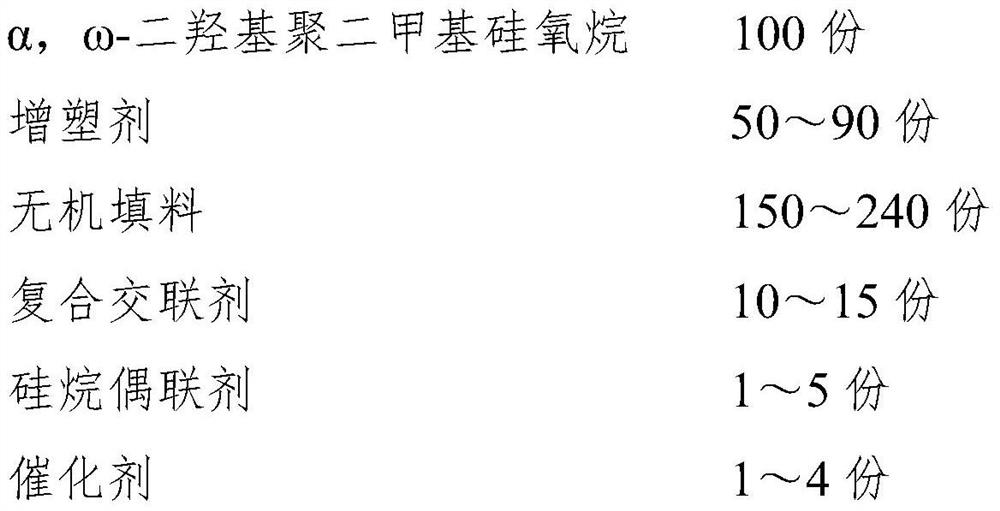

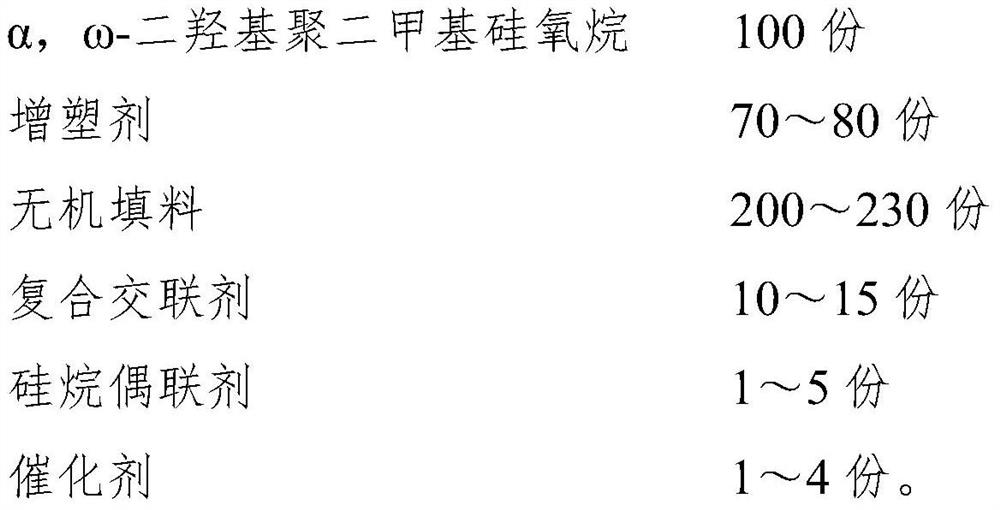

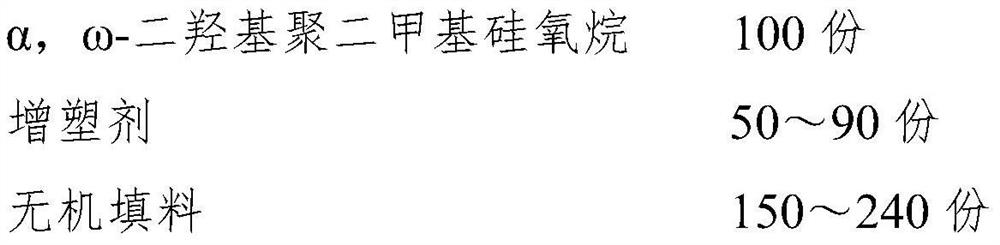

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the present invention provides a one-component dealcoholized silicone sealant, the preparation method comprising the following steps:

[0032] The first step: 100 parts of α, ω-dihydroxypolydimethylsiloxane weighing 80000mPa·s, 75 parts of No. 3 white oil, 203.6 parts of light calcium carbonate, 12 parts of composite crosslinking agent (including 1.2 parts 1,2-bistrimethoxysilylethane and 10.8 parts of propyltrimethoxysilane), 2.4 parts of complex catalyst of ethyl acetoacetate of isopropyl titanate, 2 parts of complex silane coupling agent (Contains γ-aminopropyltriethoxysilane and γ-glycidyloxypropyltrimethoxysilane, mass ratio 1:1).

[0033] Step 2: Add α, ω-dihydroxypolydimethylsiloxane and light calcium carbonate into the kneader and mix well, heat up to 120°C, vacuum -0.09MPa, speed 400rpm, knead for 90 minutes, cool to At room temperature, the base material is obtained;

[0034] Step 3: Add the base material, No. 3 white oil, and composite cros...

Embodiment 2

[0037] The embodiment of the present invention provides a one-component dealcoholized silicone sealant, the raw materials and preparation method are the same as in Example 1, the only difference is: 80000mPa·s α, ω-dihydroxy polydimethylsilane 100 parts of oxane, 70 parts of No. 3 white oil, 230 parts of light calcium carbonate, 15 parts of composite crosslinking agent (including 2.25 parts of 1,2-bistrimethoxysilylethane and 12.75 parts of propyl trimethoxy silane), 4 parts of ethyl acetoacetate complex catalyst of isopropyl titanate, 5 parts of complex silane coupling agent (including γ-aminopropyltriethoxysilane and γ-glycidyl etheroxypropyl Trimethoxysilane, mass ratio 1:1).

Embodiment 3

[0039] The embodiment of the present invention provides a one-component dealcoholized silicone sealant, the raw materials and preparation method are the same as in Example 1, the only difference is: 80000mPa·s α, ω-dihydroxy polydimethylsilane 100 parts of oxane, 50 parts of No. 3 white oil, 150 parts of light calcium carbonate, 10 parts of composite crosslinking agent (including 0.5 parts of 1,2-bistrimethoxysilylethane and 9.5 parts of propyltrimethoxy base silane), 1 part of complex catalyst of ethyl acetoacetate of isopropyl titanate, 1 part of complex silane coupling agent (including γ-aminopropyltriethoxysilane and γ-glycidyl etheroxypropyl Trimethoxysilane, mass ratio 1:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com