Antibacterial waterproof breathable film and preparation method thereof

A waterproof and breathable membrane and the technology of preparation steps, which are applied in the production of bulk chemicals, etc., can solve the problems of poor antibacterial performance, poor micropore uniformity, and low tensile strength of waterproof and breathable membranes, and achieve good waterproof, oil-proof, and anti-fouling properties. Improved antibacterial performance and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

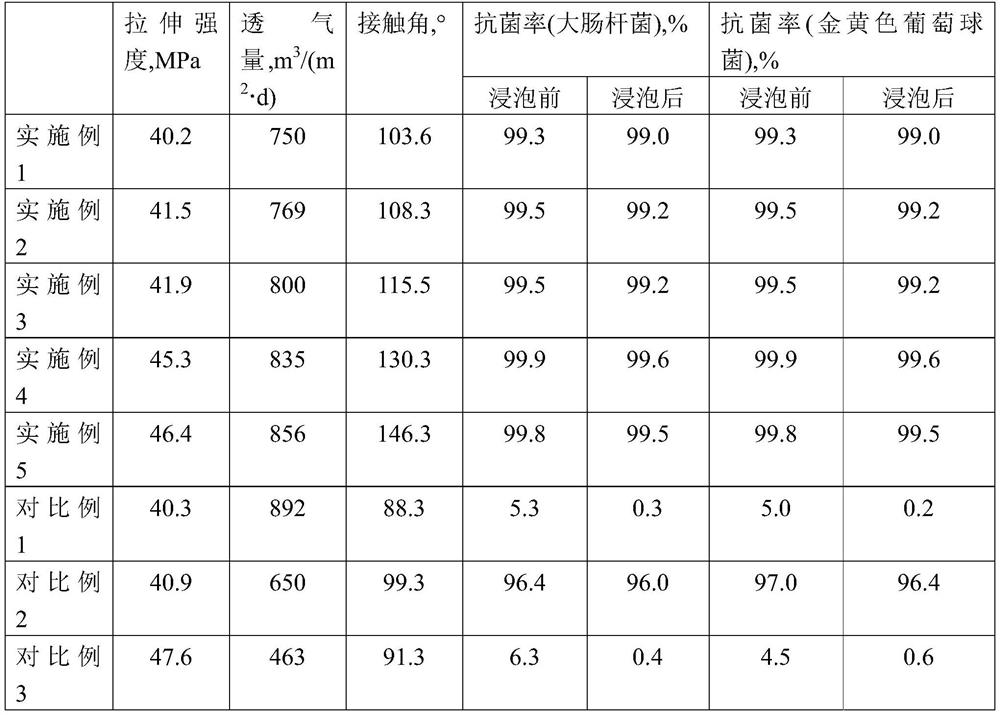

Examples

preparation example Construction

[0026]The present invention provides a method of preparing an antibacterial waterproofing membrane, and the preparation steps are as follows:

[0027]S1, polyethylene and polyethylene terephthalate is dissolved in film forming solvent, and mixed with ionic liquid is mixed and uniform, resulting in a polymer solution;

[0028]S2, add the polymer solution to the surface of the cleaned substrate, using an ultrasonic humidifier of oscillation frequency 1.7MHz ~ 2.5 MHz, microlicidal moisture, and the microductive air flow pass through a hose and nozzle port of 2 cm to 5cm inner diameter. At 3cm ~ 8cm above the substrate, the inner diameter of the nozzle is 20mm, the injection time is 15 s ~ 30s, and the solvent and the microlicidated droplets are completely volatilized, and the honeycomb microporous film is formed;

[0029]S3, a plurality of honeycomb microporous films are stacked by layer, and then placed in an annealing furnace for annealing treatment to obtain a stereo honeycomb porous film;

[...

Embodiment 1

[0058]A method of preparing an antibacterial waterproof and breathable film, the preparation steps are as follows:

[0059]S1, 10 parts by mass of polyethylene and 4 parts by mass of polyethylene terephthalate is dissolved in 40 parts by mass of dioxide carbon, and 2 parts by mass of 1-butyl-3-methylimidazole salt is added. Mix is homogeneous to give a polymer solution;

[0060]S2, add the polymer solution to the surface of the cleaned glass substrate, using an ultrasonic humidifier of the oscillation frequency 1.7 MHz ultrasonic moisture, the micro-liquid droplet passes through the hose and nozzle port of 5 cm to the substrate center 3cm At the point of the nozzle, the inner diameter is 20mm, the injection time is 15 s, and the solvent and the microlicidated droplets are completely volatilized, and the honeycomb microporous film is formed;

[0061]S3, 3 layers of honeycomb microporous film is stacked by layer, and then placed in an annealing furnace for annealing treatment to obtain a ste...

Embodiment 2

[0068]A method of preparing an antibacterial waterproof and breathable film, the preparation steps are as follows:

[0069]S1, 10 parts by weight of polyethylene and 5 parts by parts of polyethylene terephthalate is dissolved in 45 parts by parts of dioxide carbon, and 2 parts by mass of 1-ethyl-3-methylimidazoline salt is added. Mix is homogeneous to give a polymer solution;

[0070]S2, add the polymer solution to the surface of the cleaned glass substrate, using an ultrasonic humidifier of the oscillation frequency 1.7 MHz ultrasonic moisture, the microfluidic air flows through the hose and nozzle port of 4 cm to the substrate center 5cm At the point of the nozzle, the inner diameter is 20mm, the injection time is 16s, and the solvent and the microlicidated droplets are completely volatilized, and the honeycomb microporous film is formed;

[0071]S3, 3 layers of honeycomb microporous film is stacked by layer, and then placed in an annealing furnace for annealing treatment to obtain a ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com