A magnetic field-assisted lightening device and method for complex curved surfaces based on alternating magnetic field

A technology of alternating magnetic field and complex curved surface, which can be used in grinding drive devices, parts of grinding machine tools, grinding/polishing equipment, etc. Achieve the effect of flexible operation flexibility, increase reliability, and improve finishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

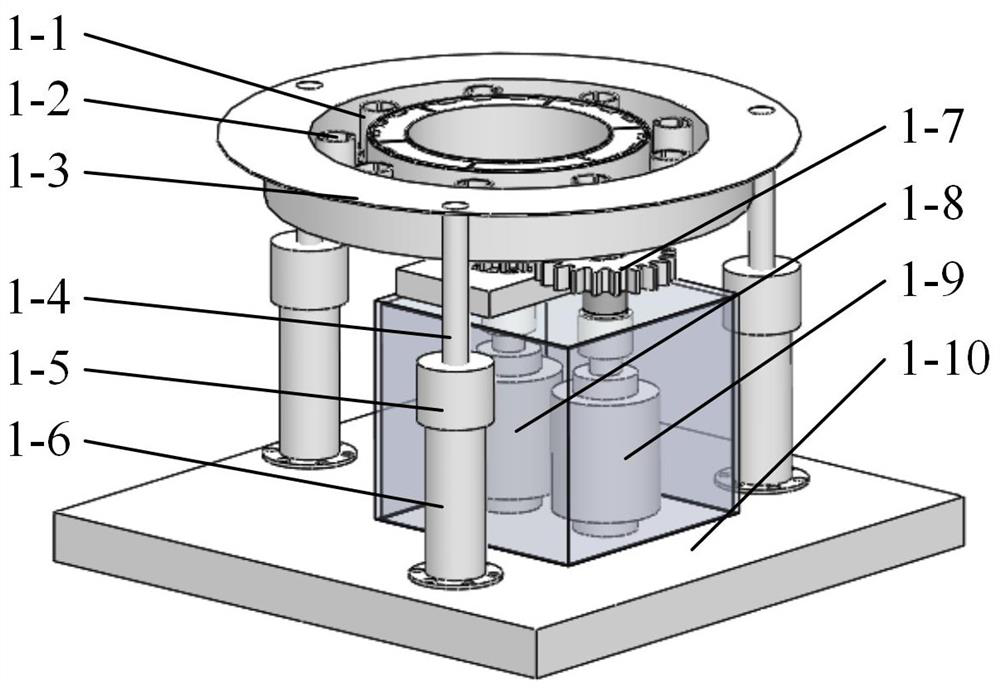

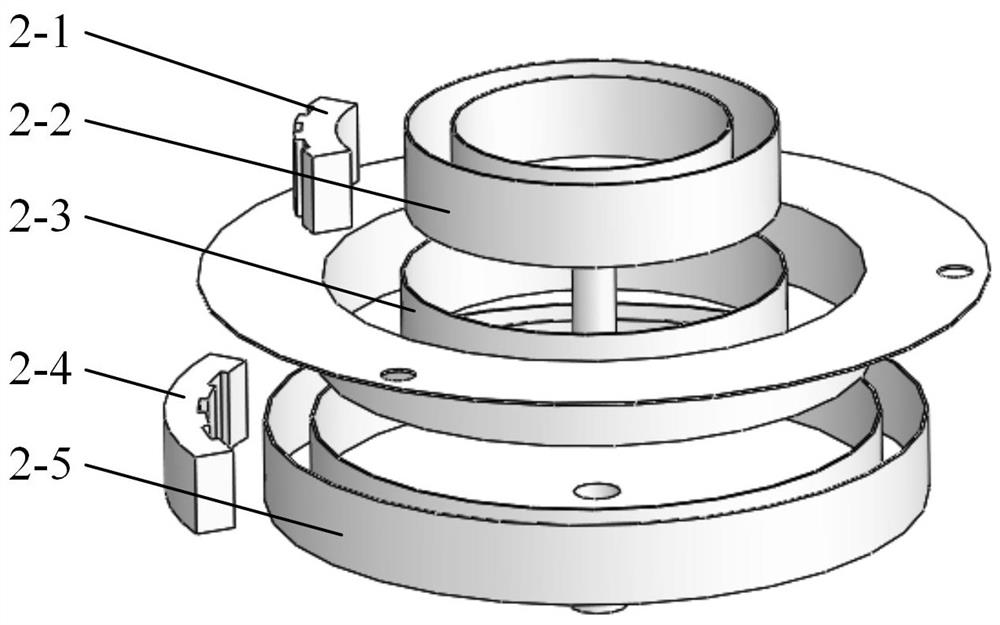

[0019] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Description The device in this embodiment includes a workpiece clamping device (1-2), a magnetic field generating device (1-3), a vibration connecting rod (1-4), a vibration motor (1-5), a supporting connecting rod (1- 6), the gear transmission mechanism (1-7), the inner annular magnetic pole groove driving motor (1-8), the outer annular magnetic pole groove driving motor (1-9) and the base (1-10), the magnetic field generating device (1 -3) Including inner annular magnetic pole (2-1), inner annular magnetic pole slot (2-2), annular baffle (2-3), outer annular magnetic pole (2-4) and outer annular magnetic pole slot (2-5) , the inner annular magnetic pole slot (2-2) equipped with the inner annular magnetic pole (2-1) is fixedly connected to the main shaft of the inner annular magnetic pole slot driving motor (1-8), and is equipped with the outer annular magnetic pole (2-4) The outer annular m...

specific Embodiment approach 2

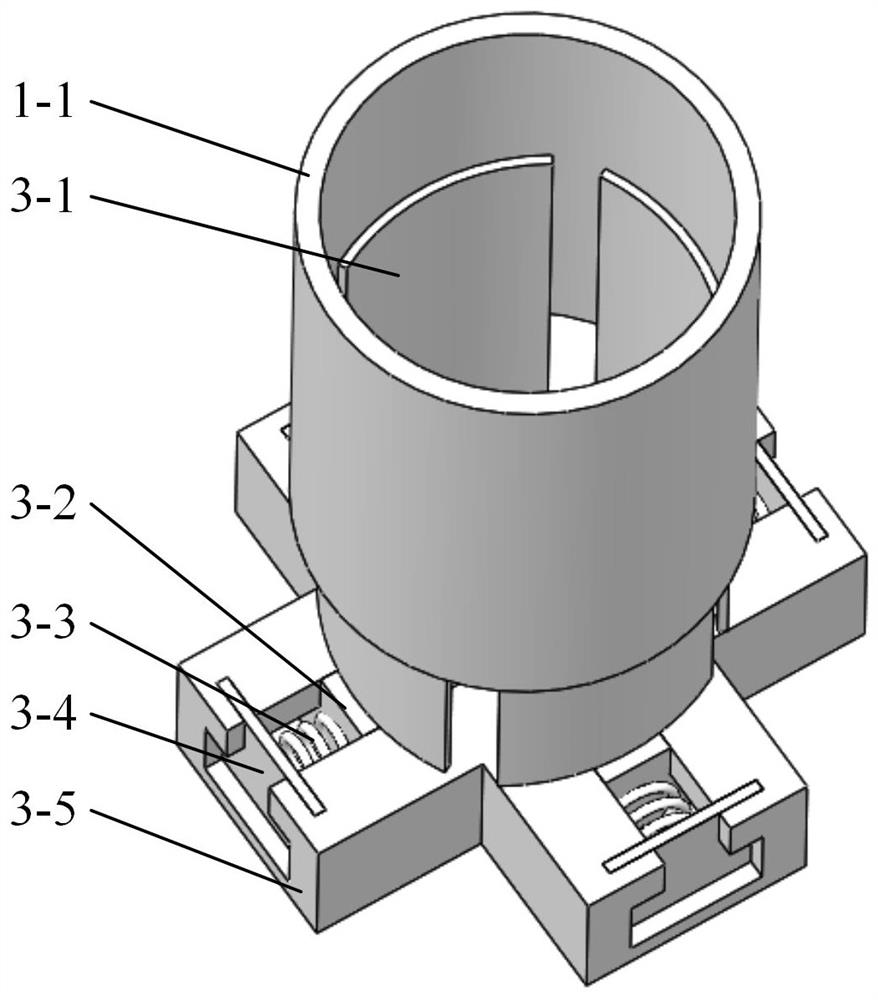

[0020] Specific implementation mode two: combination image 3 Description The workpiece clamping device (1-2) in this embodiment includes a stopper (3-1), a slider (3-2), a spring (3-3), a spring stopper (3-4) and a base ( 3-5), the retainer (3-1) is fixedly connected to the slider (3-2), one end of the spring (3-3) is connected to the slider (3-2), and the other end is fixed to the spring On the baffle (3-4), the spring baffle (3-4) is installed on the base (3-5) through interference fit, and the parts to be processed can be realized by adjusting the position of the baffle (3-1). 1-1) Clamping of different surfaces. When the stopper (3-1) is moved to make it close to the inner surface / outer surface of the part to be processed (1-1), since the spring (3-3) is in a stretched / compressed state, it is elastic Restoration force, so that the block (3-1) is tightly pressed against the inner surface / outer surface of the part to be processed, and the clamping of different surfaces of...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 Description In this embodiment, the frequency controller is used to adjust the working mode of the vibration motor (1-5) to control the trajectory of abrasive grains, thereby improving the finishing efficiency. The ring baffle (2-3) uses three vibration motors (1-5) Vibrate to ensure that the annular baffle (2-3) can receive sufficient excitation force and the magnitude of the excitation force is uniform and equal, and ensure that when a certain vibration motor (1-5) fails In this state, it can still work normally, which increases the reliability of the device. Others are the same as those of the specific embodiment 1 or 2.

[0022] Specific implementation plan four: combination figure 2 and Figure 4 Explain that the inner annular magnetic pole groove (2-2) of this embodiment can hold 6 inner annular magnetic poles (2-1), and the outer annular magnetic pole groove (2-5) can hold 6 outer annular magnetic poles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com