A kind of cu-btc MOF carbonized porous material and its preparation method and application

A technology of porous material and carbonization process, applied in the field of nanomaterials, to achieve the effects of high safety, low pollution and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

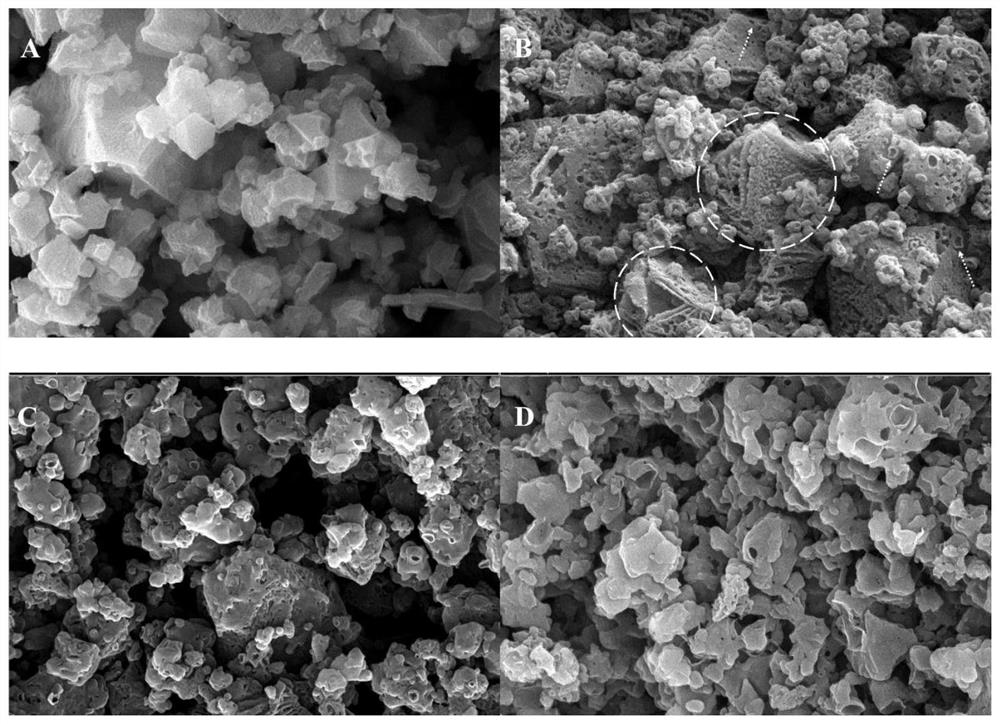

[0049] Example 1 Preparation of Cu-BTC MOF carbonized porous material

[0050] A certain amount of Cu-BTC MOF material was ground into a uniform blue powder, baked at 105°C for 12h, then taken out and cooled to room temperature. A certain amount of baked Cu-BTC MOF material was poured into a corundum crucible, and then three temperature gradient conditions (400°C, 600°C, 800°C) were set. The amount of material used for each temperature gradient was 10g. 2 Under protection, the heating rate is 1°C / min, and the annealing time is 3h. After the tube furnace is cooled to room temperature, the calcined material is taken out and ground evenly, and then washed with concentrated hydrochloric acid. The dosage is 0.5L each time. Overnight, pour off the supernatant, repeat this process until the supernatant is colorless and transparent, take a small amount of supernatant and use 1mg / mL sodium hydroxide solution to verify whether the copper ions are washed clean, after the pickling, contin...

Embodiment 2

[0054] Example 2 Cu-BTC MOF and Cu-BTC MOF carbonized materials have an effect on AFB in 0.05% methanol aqueous solution 1 Compared with the adsorption effect

[0055] Prepare a certain number of centrifuge tubes, and add 10ml of AFB with a concentration of 100ng / ml to each tube 1 Working solution, accurately weigh 10 mg of Cu-BTC MOF and the three kinds of Cu-BTC MOF carbonized materials prepared in Example 1 and place them in centrifuge tubes with standard solutions, vortex for 10 seconds, and place the centrifuge tubes at room temperature in the dark. Place on a shaking table for adsorption treatment, wherein the rotating speed of the shaking table is 250rpm, and the adsorption time is 24h. After centrifugation, take 1 mL of the supernatant to pass through a 0.22 μm organic membrane, and then use HPLC to detect the aflatoxin content in the supernatant; at the same time, do a set of blank control treatment (CK, that is, without adding Cu-BTC MOF or C-Cu-BTC MOF material , ...

Embodiment 3

[0057] Example 3 Effect of Cu-BTC MOF carbonized porous material on AFB in 0.05% methanol aqueous solution 1 The adsorption properties of

[0058] 1) Effect of different adsorption times on Cu-BTC MOF carbonized porous material on AFB in 0.05% methanol aqueous solution 1 The influence of the adsorption performance

[0059] Weigh 30mg of C-Cu-BTC MOF-400, C-Cu-BTC MOF-600, and C-Cu-BTC MOF-800 respectively, and place them in 100mL of AFB with a concentration of 5μg / mL 1 0.05% methanol aqueous solution (250mL beaker), vortexed for 10s and carried out magnetic stirring adsorption at room temperature and dark conditions, the rotation speed was 250rpm, and the adsorption times were 0, 5, 10, 15, 20, 25, 30, 35, 40, 50, 60, 90, 120, 150, 180, 240, 360, 480, 720, 840, 1440min, take 1mL of the supernatant to pass through the 0.22μm organic film twice at the above time, and then use the GB 5009.22-2016 method to detect yellow Aspergillus toxin, for result verification, the result is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com