A water-based polyester copolymer and preparation method and application thereof

A water-based polyester and copolymer technology, applied in the field of coatings, can solve the problems of solvent resistance decline, affecting the molecular weight and distribution of polyester, affecting the degree of curing of coatings, etc., to achieve the effect of achieving a comprehensive performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment provides a kind of environmental protection catalyst CATA1, and its preparation method comprises the following steps:

[0057] (1) A total of 3.15 g of butyl titanate and n-propyl titanate composition was placed in 22 mL of hydrochloric acid aqueous solution (0.025 mol / L) for hydrolysis to obtain Sol A; 3.92 g of propyl titanate was placed in 23 mL containing Hydrolysis of ethanol in hydrochloric acid aqueous solution (0.025mol / L) obtains sol B; Sol A is mixed with sol B to obtain sol C; wherein the molar ratio of titanium element and silicon element in sol C is 4:6;

[0058] (2) Slowly add sol C dropwise to the aqueous solution of amine compounds (composition of (R)-spirocyclic diamine and caprolactam total 2.8g, water 143g), obtain white flocculent precipitate, use deionized water repeatedly Centrifugal washing to free of chloride ions, drying at 65°C to constant weight, and then crushing treatment to obtain an environmentally friendly catalyst ...

Embodiment 2

[0060] The present embodiment provides a kind of environmental protection catalyst CATA2, and its preparation method comprises the following steps:

[0061] (1) A total of 4.85 g of the composition of butyl titanate and isopropyl titanate was placed in 26 mL of aqueous hydrochloric acid (0.025 mol / L) for hydrolysis to obtain Sol A; 5.1 g of tetraethyl orthosilicate was placed in 23 mL Hydrolysis in ethanol-containing hydrochloric acid aqueous solution (0.025mol / L) to obtain Sol B; Sol A was mixed with Sol B to obtain Sol C; wherein the molar ratio of titanium and silicon in Sol C was 6:4;

[0062] (2) Slowly add sol C dropwise to an aqueous solution of amine compounds ((R)-spirocyclic diamine, a composition of caprolactam and N,N-dimethylamide totaling 3.56g, water 158g) to obtain a white floc Centrifuge and wash repeatedly with deionized water until there is no chloride ion, dry at 89°C to constant weight, and then pulverize to obtain an environmentally friendly catalyst CATA...

Embodiment 3-5

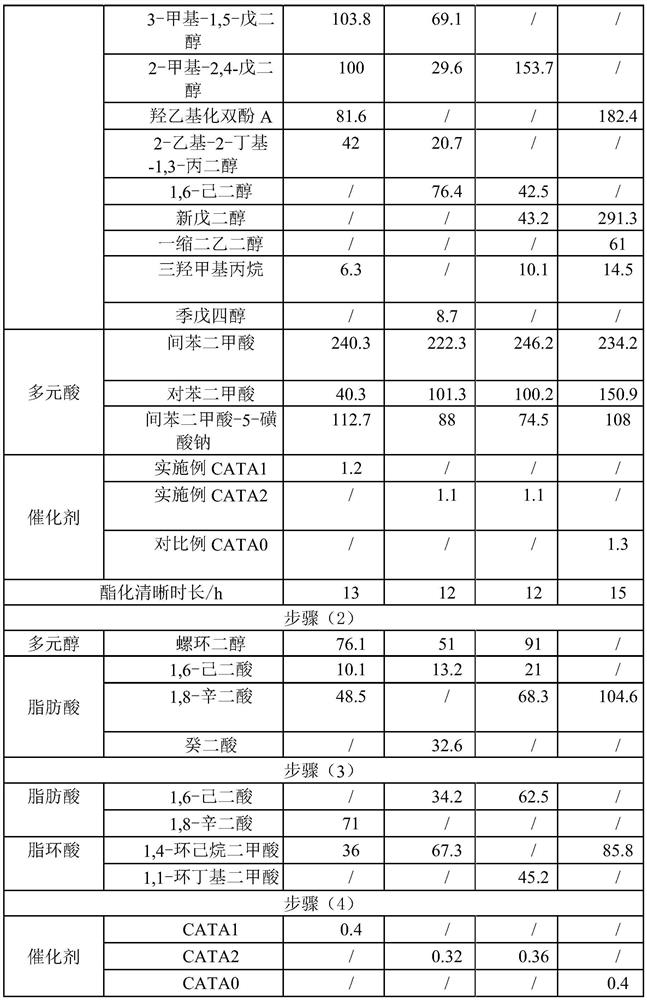

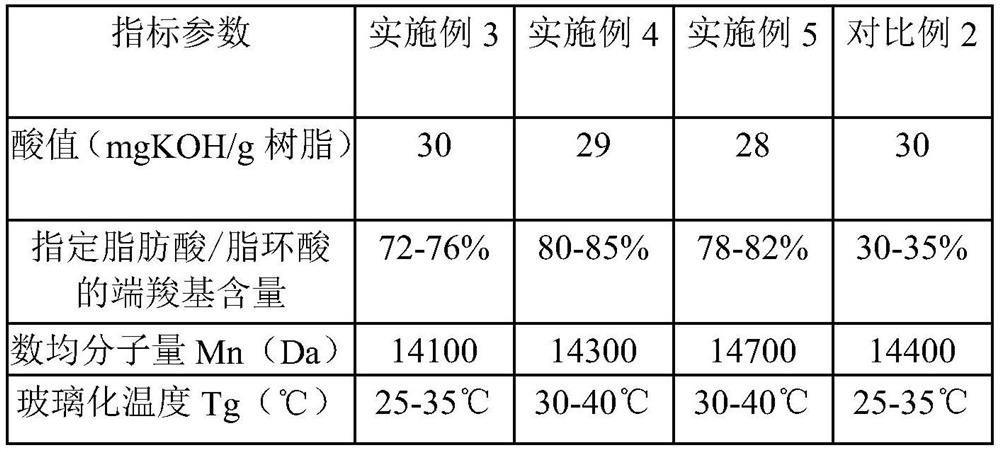

[0067] Embodiment 3-5 provides a kind of aqueous polyester copolymer respectively, and its specific preparation method comprises the following steps (wherein the raw material composition and consumption in each step are shown in Table 1):

[0068] (1) In the reaction still equipped with agitator, thermometer, reflux condenser and nitrogen gas, part of spirocyclic glycol, part of environmental protection catalyst, aromatic polybasic acid, sulfonic acid group containing dibasic acid (ester) and Add other polyols into the reaction vessel together, and react at a temperature of 220-240°C under the condition of nitrogen as a protective gas, and keep the temperature for 1-3 hours until the acid value of the system drops below 20mgKOH / g.

[0069] (2) Under the temperature of keeping step (1), add remaining spiro diol and part of fatty acid to react, and react until the acid value of the system is reduced to below 25mgKOH / g;

[0070] (3) Cool down to 210-230°C, add alicyclic acid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com