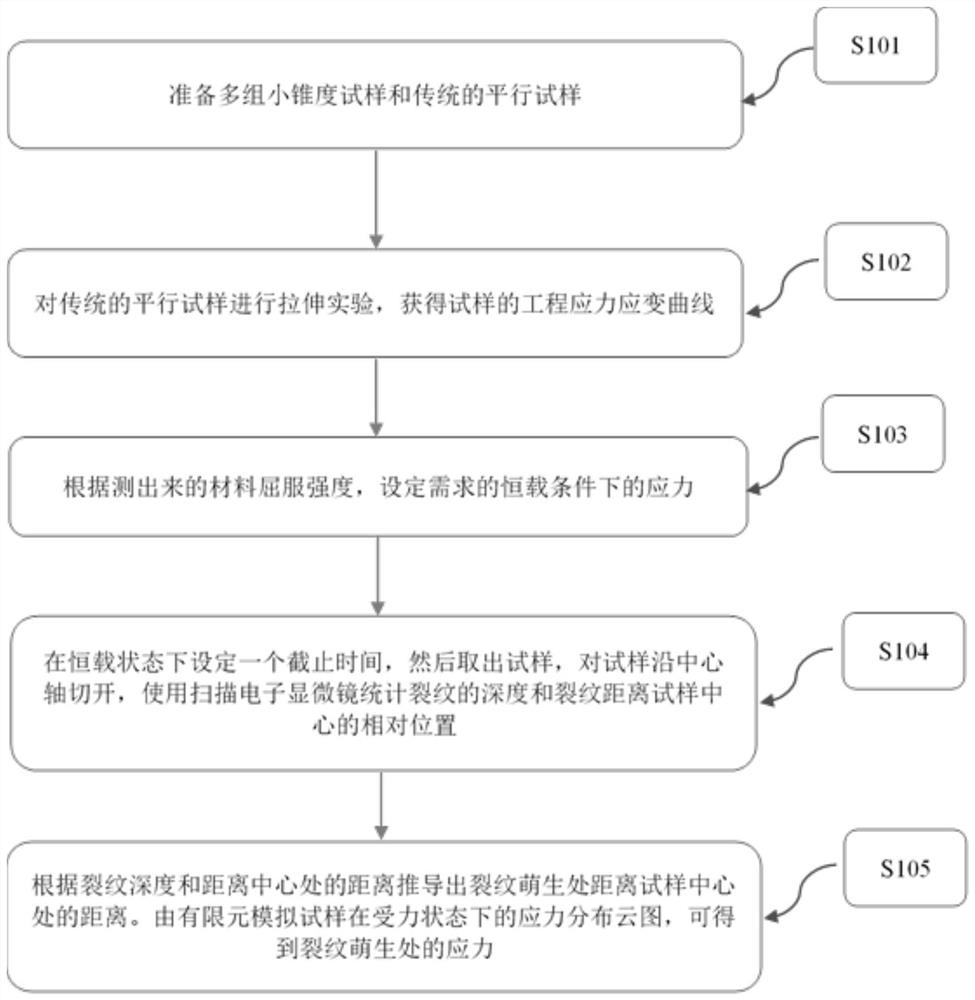

Method for predicting crack initiation stress by combining small taper experiment with simulation

A taper and crack technology, which is applied in the field of small taper experiment combined with simulation to predict crack initiation stress, can solve problems such as time-consuming, and achieve the effect of small result error, saving experimental materials, and reducing experimental period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

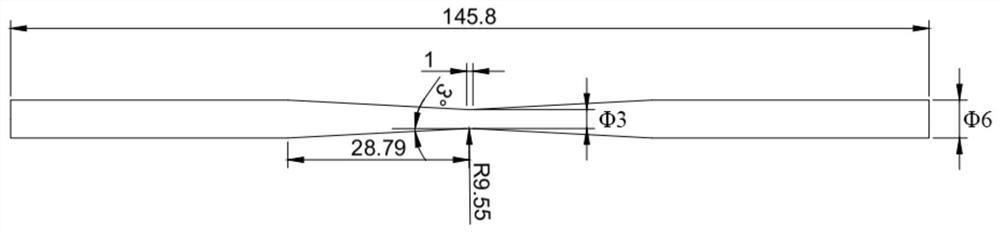

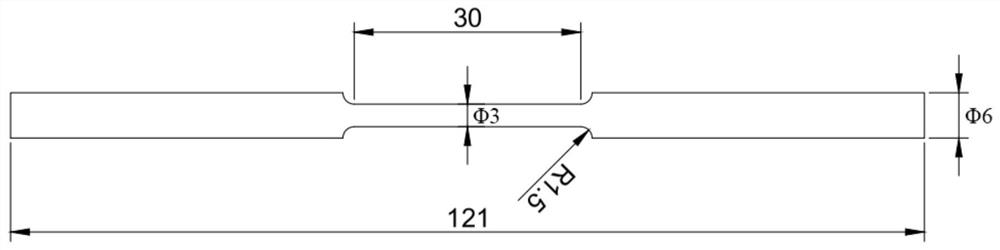

[0050] In this example, sample dimensions such as figure 2 As shown, put the sample into 0.5mol / L sulfuric acid plus 0.5g / L thiourea for electrochemical hydrogen charging, and the hydrogen charging current density is 2mA / cm 2 , the time is 200h. Applied nominal stress is 600MPa, such as Figure 4 , because the stress at the center of the sample has exceeded its yield strength, the actual stress there is greater than 600MPa, and the specific value is given by the finite element. After the experiment, the sample was cut along the central axis, and the crack depth on the edge of the sample and the distance from the crack to the center of the sample were counted, as shown in Figure 5 shown. The predicted crack initiation distance from the center of the sample is 4173 μm. According to the finite element simulation results, the stress value of crack initiation under this condition is 487.42 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com