Digital laser explosion loading dynamic photoelastic experiment system

An experimental system, dynamic photoelastic technology, is applied in the direction of measuring the change force of the optical properties of the material when it is stressed, and can solve the problems of high operation and experience requirements, low experimental success rate, unfavorable research, etc., and achieve the goal of using Convenience, reliable operation, increased controllability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

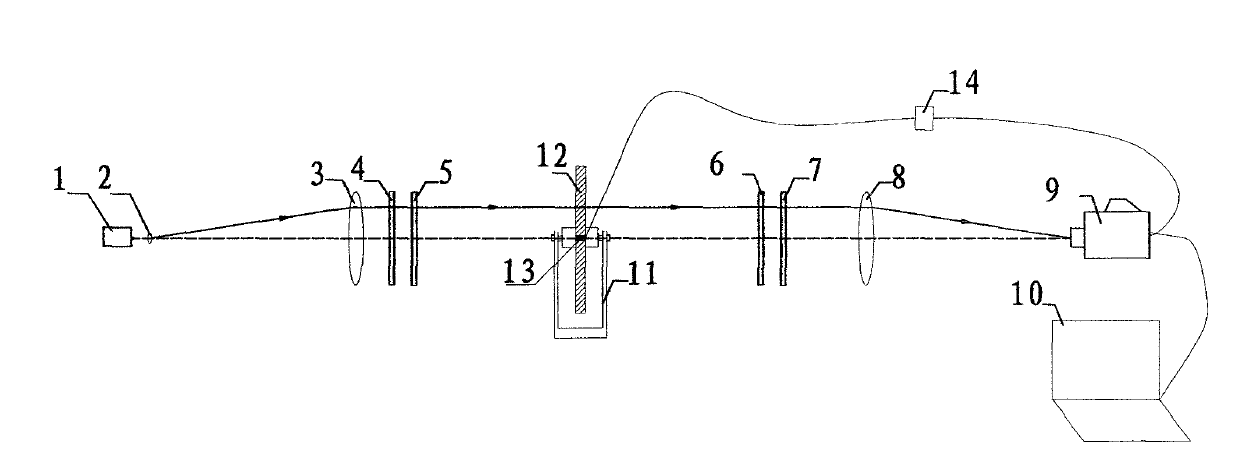

[0028] like figure 1 As shown, a digital laser explosion loaded dynamic photoelastic experiment system includes a laser 1, a beam expander 2, a front convex lens 3, a polarizer 4, a left 1 / 4 wave plate 5, a right 1 / 4 wave plate 6, a detector Polarizer 7, rear convex lens 8, explosive loading device 11, detonator 14, digital high-speed camera 9 and computer 10.

[0029] Wherein, the output end of the laser 1 corresponds to the beam expander 2 , and the beam expander 2 is located between the laser 1 and the front convex lens 3 . The front convex lens 3 in the field lens combination is responsible for converting the surface beam emitted by the beam expander 2 into a parallel beam, and then converges and transmits it through the rear convex lens 8 . Between the front and rear convex lenses 3 and 8, a polarizer 4, a left 1 / 4 wave plate 5, a right 1 / 4 wave plate 6, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com