High-temperature alloy with gradient nanostructure surface layer and preparation method of high-temperature alloy

A high-temperature alloy and nanostructure technology, which is applied in the field of nanometerization of the surface of metal materials, can solve the problems of insufficient mechanical properties, uneven microstructure, and coarse grains on the surface layer, and achieves high mechanical properties, large hardness gradient, and simple processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The method for preparing a superalloy with a surface layer of a gradient nanostructure comprises the following steps: processing the superalloy with surface mechanical grinding technology, pressing a processing tool into the surface of the material to a certain depth, and passing the spherical head at the front end of the processing tool to Grinding produces gradient plastic deformation on the surface of the material. The superalloy treatment is completed on the surface nano-processing system, such as figure 1 As shown, the processing system includes a rotating system 1 , a tool holder feeding system 2 , a processing tool 3 and a cooling system 4 . The rotating system 1 and the tool post feeding system 2 are realized by a numerically controlled lathe, which provide rotary motion and feeding motion respectively; the processing tool 3 is installed on the tool post feeding system 2, and the front end is equipped with a spherical head with a certain radius of curvature ; T...

Embodiment 1

[0041] Process J75 iron-based superalloy parts with a diameter of 13mm, its chemical composition is (wt.%): Ni 30.8%, Cr14.87%, Mo 1.31%, V 0.24%, Ti 1.88%, Al 0.36%, Si 0.19% , B 0.0008%, the balance of Fe; the heat treatment state is a solid solution state.

[0042] Using the present invention to carry out surface nano-processing, the material of the spherical head at the front end of the processing tool is hard alloy, and the radius of curvature is 4mm. Speed V of J75 iron-based high-temperature alloy parts 1 =300r / min; the feed speed V of the processing tool 2 =9mm / min; each pressing amount of the processing tool a p =20um, the processing pass is 6 times; oily cutting fluid is used for cooling and lubrication during processing.

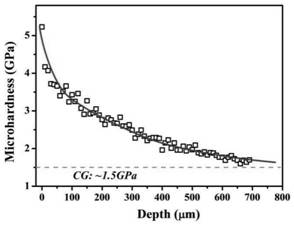

[0043] The test results show that after surface nano-treatment, a gradient structure layer about 500um thick is formed on the surface of J75 iron-based superalloy parts, in which the thickness of the nanocrystalline layer is 60μm, the thickne...

Embodiment 2

[0045] Process Inconel718 nickel-based superalloy parts with a diameter of 14mm, its chemical composition is (wt.%): Fe19.1%, Cr 17.91%, Mo 3.01%, Nb 5.32%, Ti 0.96%, Al 0.45%, C 0.026% , Ni balance; the heat treatment state is a solid solution state.

[0046] Using the present invention to carry out surface nano-processing, the material of the spherical head at the front end of the processing tool is hard alloy, and the radius of curvature is 4mm. Speed V of solid solution Inconel718 nickel-based superalloy parts 1 =500r / min; the feed speed V of the processing tool 2 =8mm / min; each pressing amount of the processing tool a p =20um, the processing pass is 6 times; oily cutting fluid is used for cooling and lubrication during processing.

[0047] The test results show that after surface nano-treatment, a gradient structure layer about 350um thick is formed on the surface of the solid solution state Inconel718 nickel-based superalloy parts, in which the thickness of the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com