Dry-method ultra-clean emission dust removal device

A technology of dust removal device and dry method, which is applied in the direction of manufacturing converters, improving process efficiency, and improving energy efficiency. It can solve the problems of water consumption, waste liquid, high energy consumption of dust removal, and large flue gas volume, and achieve scalability. Good performance, perfect safety measures, and low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

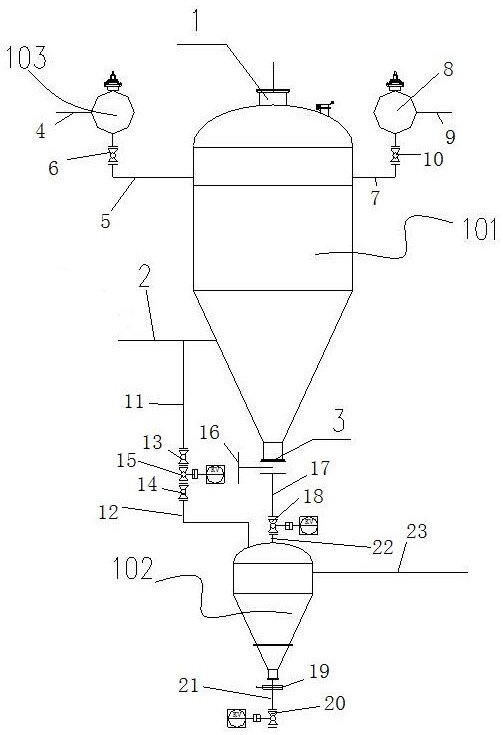

[0014]Such asfigure 1A dry ultimate exhausting device, including a high temperature metal compound filter bag dust collector 101, and a reverse blow tube 5 connected to the high temperature metal compound filter bag dust collector 101, and the first connection with the anti-blow tube 5 The manual ball valve 6, and the first nitrogen reverse blowing package 103 connected to the first hand moving ball valve 6, and the first nitrogen reverse blowing air tube 4 connected to the first nitrogen reverse blowing package 103, and is provided in high temperature metal High temperature metal compound filter bag dust collector outlet 1, high temperature metal compound filter bag dust collector inlet 1, high temperature metal compound filter bag dust collector unloading gray port 3, and high temperature intermetallic compound Filter bag dust collector unloading the ash port 3 connected to the immersion tube 17, and the first control valve 16, the first air valve 18, and the first air valve 18, t...

Embodiment 2

[0016]Such asfigure 1A dry ultimate exhausting device, including a high temperature metal compound filter bag dust collector 101, and a reverse blow tube 5 connected to the high temperature metal compound filter bag dust collector 101, and the first connection with the anti-blow tube 5 The manual ball valve 6, and the first nitrogen reverse blowing package 103 connected to the first hand moving ball valve 6, and the first nitrogen reverse blowing air tube 4 connected to the first nitrogen reverse blowing package 103, and is provided in high temperature metal High temperature metal compound filter bag dust collector outlet 1, high temperature metal compound filter bag dust collector inlet 1, high temperature metal compound filter bag dust collector unloading gray port 3, and high temperature intermetallic compound Filter bag dust collector unloading the ash port 3 connected to the immersion tube 17, and the first control valve 16, the first air valve 18, and the first air valve 18, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com