High-adhesion low-modulus epoxy adhesive and preparation method thereof

An epoxy adhesive, low modulus technology, applied in the direction of adhesives, epoxy resin glue, polymer adhesive additives, etc., can solve the problems of low adhesion, colloidal strength reduction, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

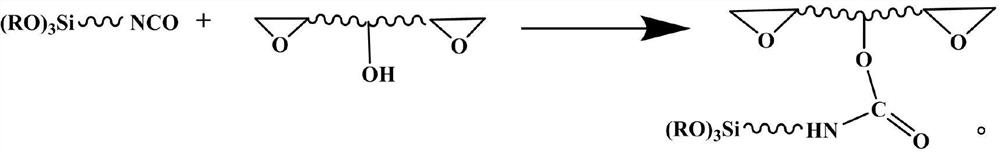

Method used

Image

Examples

Embodiment 1

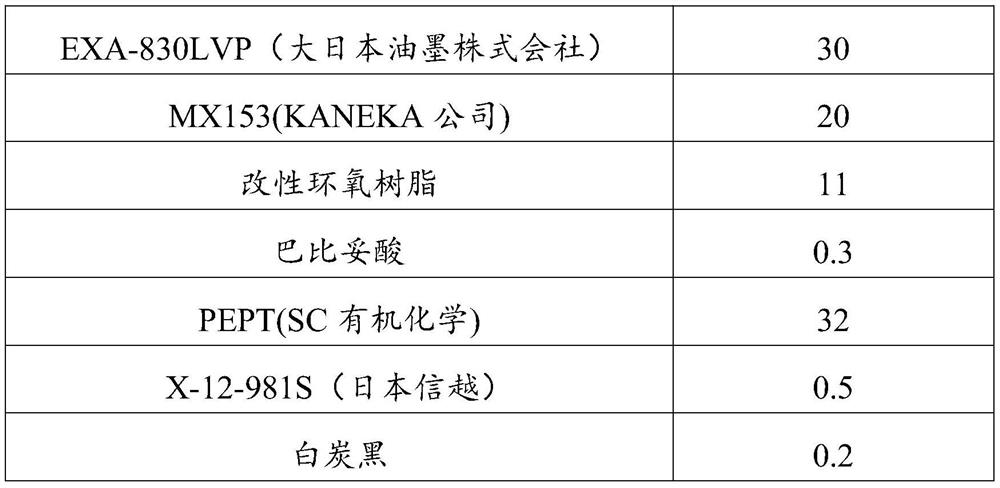

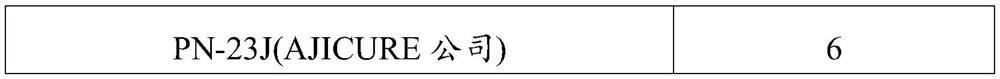

[0016] The formulation of a high-adhesion low-modulus epoxy adhesive is shown in Table 1.

[0017] Table 1

[0018]

[0019]

[0020] The preparation method of the high-adhesion low-modulus epoxy adhesive in this embodiment is: add EXA-830LVP, MX153, modified epoxy resin, barbituric acid, PEPT and X-12-981S to the double planet Stir in a stirring tank for 20 minutes under vacuum; add white carbon black, mix evenly under vacuum, stir at high speed for 2 hours, then age at room temperature for 16 hours, and finally add PN23J to it, stir under vacuum for 2 hours, mix evenly, and then discharge .

Embodiment 2

[0022] The formulation of a high-adhesion low-modulus epoxy adhesive is shown in Table 2.

[0023] Table 2

[0024] Epon 828 (Hexion Inc, USA) 35 BPA328 (Nippon Shokubai, Japan) 10 Modified epoxy resin 13 salicylic acid 0.5 THIOCURE PE1 (BRUNO BOCK) 30 X-12-981S (Shin-Etsu) 1 Silica 0.5 7501 (Fuijicure) 10

[0025] The preparation method of the high-bonding low-modulus epoxy adhesive in this embodiment is: add Epon 828, BPA328, modified epoxy resin, salicylic acid, THIOCURE PE1 and X-12-981S to the double planetary stirring In the kettle, stir for 20min under vacuum; then add white carbon black to the dual planetary stirring kettle, mix evenly under vacuum, stir at high speed for 2h, then age at room temperature for 14h, finally add 7501 into it, and mix at low speed under vacuum Stir for 1 hour to mix evenly and discharge.

Embodiment 3

[0027] The formulation of a high-adhesion low-modulus epoxy adhesive is shown in Table 3.

[0028] table 3

[0029] EP4901E 30 BPA328 (Nippon Shokubai, Japan) 21 Modified epoxy resin 5 fumaric acid 0.4 THIOCURE TMPMP (BRUNO BOCK) 35 X-12-1154 (Shin-Etsu) 1.5 Silica 0.1 7501 (Fuijicure) 7

[0030] The preparation method of the high-adhesion low-modulus epoxy adhesive in this example is: add EP4901E, BPA328, modified epoxy resin, fumaric acid, TMPMP and X-12-1154 into a double planetary stirring tank by weight , stirred for 20 minutes under vacuum; then added white carbon black to the double planetary stirring tank, mixed evenly under vacuum and stirred at high speed for 2 hours, then aged at room temperature for 14 hours, finally added 7501 to it, and stirred at low speed for 1 hour under vacuum Discharge after mixing evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com