Coating for converter slag-stopping sliding brick and preparation method thereof

A converter slag blocking and sliding brick technology, which is applied in the direction of coating, can solve the problems affecting the performance and life of the coating, and achieve the effects of prolonging the service life, enhancing the strength and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

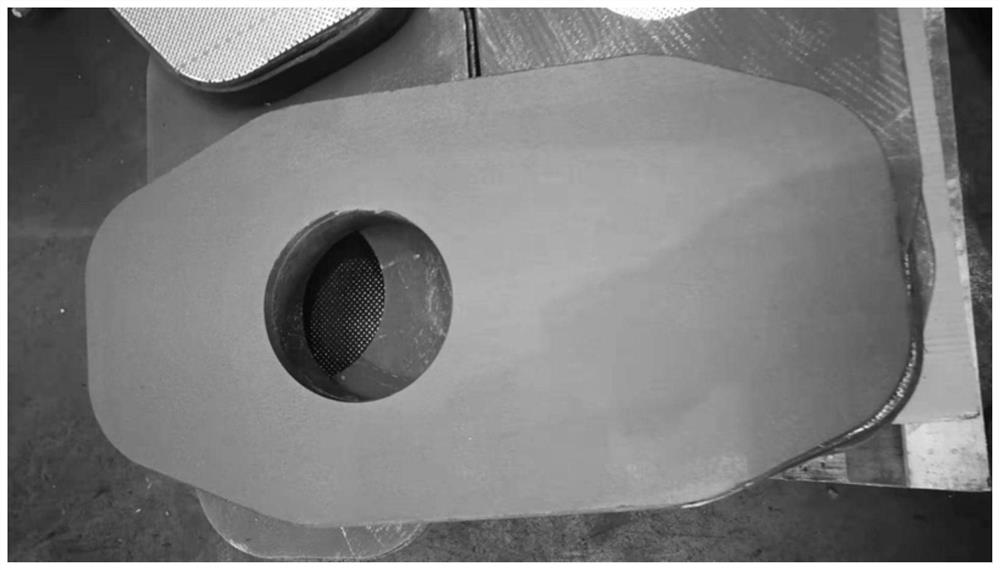

Image

Examples

Embodiment 1

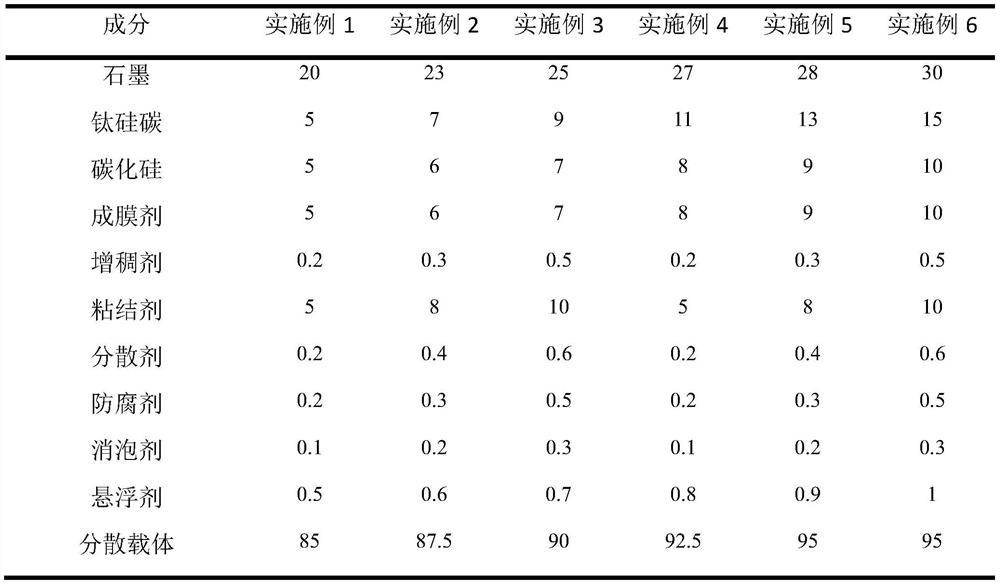

[0038] A kind of coating for converter slag retaining slide brick of the present embodiment, the mass fraction of its component is:

[0039] 20 parts of modified flake graphite; 5 parts of titanium silicon carbon; 5 parts of silicon carbide; 5 parts of styrene-acrylic emulsion; 0.2 parts of carboxymethyl cellulose; 5 parts of solid dihydrogen phosphate Aluminum; 0.2 parts of polyvinylpyrrolidone; 0.2 parts of Cathone; 0.1 parts of propylene oxide; 0.5 parts of sodium bentonite and 85 parts of deionized water.

[0040] Specifically, using the above-mentioned raw materials to prepare the method for preparing the coating for the converter slag-stopping sliding brick of this embodiment, the steps are:

[0041] (1) Prepare the matrix mixed powder: mix the matrix mixed powder according to the ratio of raw materials by mass, add 20 parts of graphite, 5 parts of titanium silicon carbon and 5 parts of silicon carbide to the planetary ball mill for ball milling and mixing Dispersion, b...

Embodiment 2

[0046] A kind of coating for converter slag retaining slide brick of the present embodiment, the mass fraction of its component is:

[0047] 23 parts of modified flake graphite; 7 parts of titanium silicon carbon; 6 parts of silicon carbide; 6 parts of ethylene glycol; 0.3 parts of sodium polyacrylate; 8 parts of magnesium phosphate; 0.4 parts Tween; 0.3 parts of potassium sorbate; 0.2 parts of propylene oxide; 0.6 parts of polyethylene glycol and 87.5 parts of deionized water.

[0048] Specifically, using the above-mentioned raw materials to prepare the method for preparing the coating for the converter slag-stopping sliding brick of this embodiment, the steps are:

[0049] (1) Prepare the matrix mixed powder: mix the matrix mixed powder according to the ratio of raw materials by mass, add 23 parts of graphite, 7 parts of titanium silicon carbon and 6 parts of silicon carbide to the planetary ball mill for ball milling and mixing Dispersion, ball milling time is 1 to 2 hours...

Embodiment 3

[0054] A kind of coating for converter slag retaining slide brick of the present embodiment, the mass fraction of its component is:

[0055] 25 parts of modified flake graphite; 9 parts of titanium silicon carbon; 7 parts of silicon carbide; 7 parts of styrene-acrylic emulsion; 0.5 parts of polyacrylamide; 10 parts of magnesium phosphate; 0.6 parts Tween; 0.5 parts of benzoic acid; 0.3 parts of polydimethylsilane; 0.7 parts of xanthan gum and 90 parts of deionized water.

[0056] Specifically, using the above-mentioned raw materials to prepare the method for preparing the coating for the converter slag-stopping sliding brick of this embodiment, the steps are:

[0057] (1) Prepare the matrix mixed powder: mix the matrix mixed powder according to the ratio of raw materials by mass, add 25 parts of graphite, 9 parts of titanium silicon carbon and 7 parts of silicon carbide to the planetary ball mill for ball milling and mixing Dispersion, ball milling time is 1 to 2 hours;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com