Method for preparing PPEs high-fluorescence nanoparticles

A fluorescent nanometer and particle technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of accuracy and sensitivity of PPEs fluorescent probes, reduce fluorescence and other problems, increase water solubility and biocompatibility, protect Fluorescence, the effect of expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] S1. Synthesis of PPEs-OH

[0030] Add 1.00mmol 2-(2,5-diiodo-4-methyl)phenylethanol, 1.00mmol 1,4-diethynyl-2,5-dioctyloxybenzene and 1.60mL piperazine into a Schlenk flask Pyridine, with 1.60mL tetrahydrofuran (THF), dissolve the three substances, then add 0.1μmol bistriphenylphosphine palladium dichloride ((PPh 3 ) 2 PdCl 2 ), 1.80 μmol cuprous iodide (CuI) mixed, stirred at room temperature for 24h;

[0031] The obtained polymer was extracted with 1ml of dichloromethane each time, extracted 3 times, and the solvent was removed by vacuum evaporation to obtain a solid, which was washed successively with 10% ammonia water and 10% hydrochloric acid; Methane extraction, after extraction 3 times, settling with methanol, filtering to obtain dark green solid P0;

[0032] S2. Synthesis of PPEs-PCL: Take 10 mg of the sample PPEs-OH prepared by S1, dry it under oil pump vacuum at 70 °C, add 0.2 ml ε-caprolactone, heat the mixture to 110 °C until the polymer is dissolved, th...

Embodiment 2

[0036] S1. Synthesis of PPEs-OH

[0037] Add 2.00mmol 2-(2,5-diiodo-4-methyl)phenylethanol, 2.00mmol 1,4-diethynyl-2,5-dioctyloxybenzene and 3.20mL piperazine into a Schlenk flask Pyridine, use 3.20mL tetrahydrofuran (THF), dissolve the three substances, then add 0.2μmol bistriphenylphosphine palladium dichloride ((PPh 3) 2 PdCl 2 ), 3.60 μmol cuprous iodide (CuI) mixed, stirred at room temperature for 24 hours;

[0038] The obtained polymer was extracted with 2ml of dichloromethane each time, extracted 3 times, and the solvent was removed by vacuum evaporation to obtain a solid, which was washed with 10% ammonia water and 10% hydrochloric acid successively; Methane extraction, after extraction 3 times, settling with methanol, filtering to obtain dark green solid P0;

[0039] S2. Synthesis of PPEs-PCL: Take 100 mg of the sample PPEs-OH prepared by S1, dry it under oil pump vacuum at 70 °C, add 2 ml ε-caprolactone, heat the mixture to 110 °C until the polymer is dissolved, ...

Embodiment 3

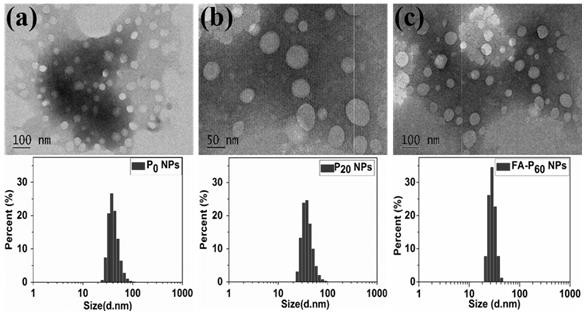

[0043] A. Synthesis of PPEs-PCL: Take 100 mg of the sample P20 prepared in step S2 in Example 2, dry it under 70°C oil pump vacuum, add 4mlε-caprolactone, heat the mixture to 110°C until the polymer is dissolved, and then After adding stannous octoate (1 mg, 3 mol), the reaction stopped after the mixture solidified. The product was dissolved in chloroform, settled with methanol, filtered, and dried under oil pump vacuum to obtain the product P60.

[0044] B. PPEs-PCL and PCL 2K -PEG 5K Co-assembly: 1.00mgPPEs-PCL and 11mgPCL prepared in step A 2K -PEG 5K (purchased from the market) was dissolved in 1 ml, and the mixture was dripped into 15 ml of deionized water for 1 h under vortex, then dialyzed with a dialysis bag to remove tetrahydrofuran, and freeze-dried at -50°C to obtain a yellow powder.

[0045] According to the above fluorescence detection method, the fluorescence quantum yield of the target object prepared in Example 3 was 0.78.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com