Anti-blocking explosion-proof valve and preparation method thereof

An explosion-proof valve and anti-clogging technology, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of affecting the exhaust and pressure relief speed of explosion-proof valves, the impact of explosion-proof valve core opening strokes, and the reduction of valve core opening heights, etc. , to achieve the effect of avoiding short circuit or other accidents, balancing internal and external pressure, improving exhaust capacity and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

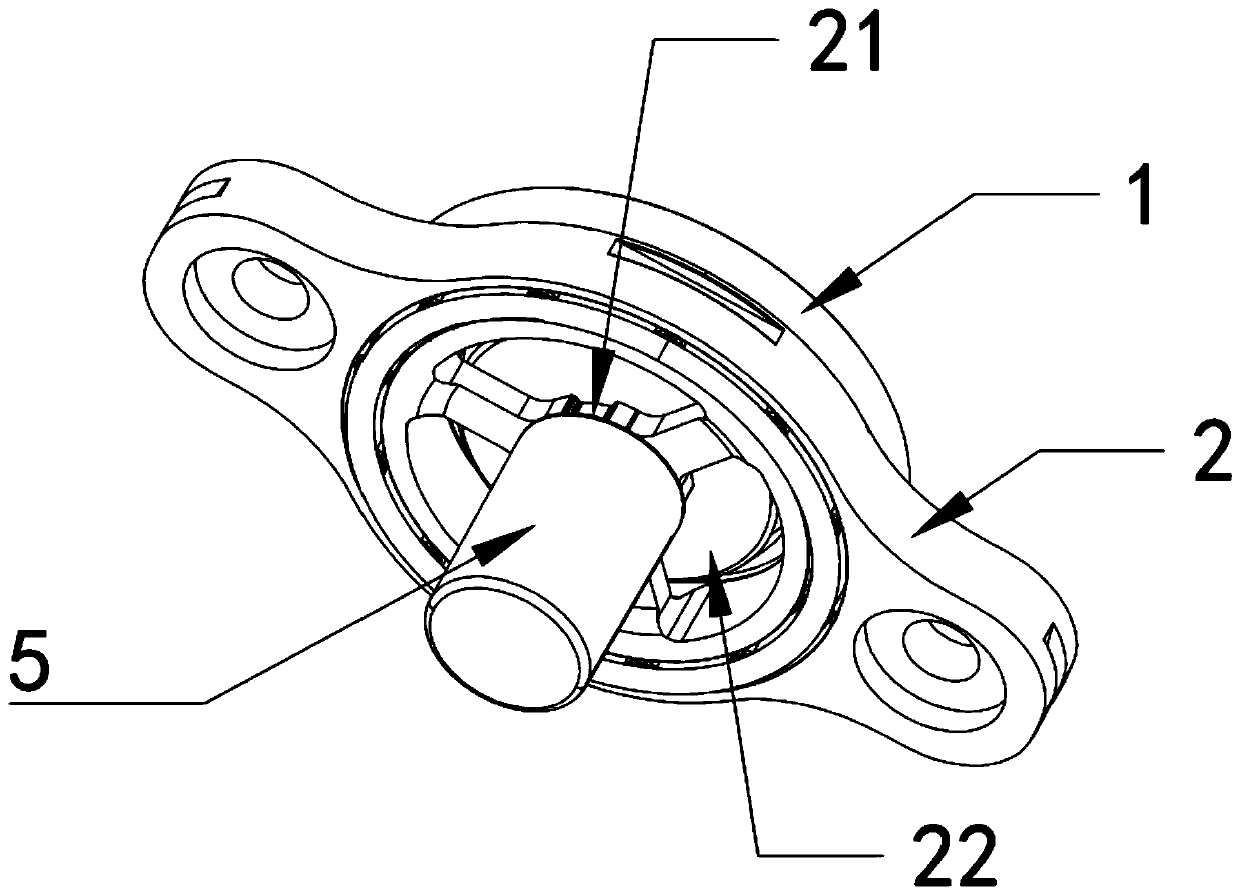

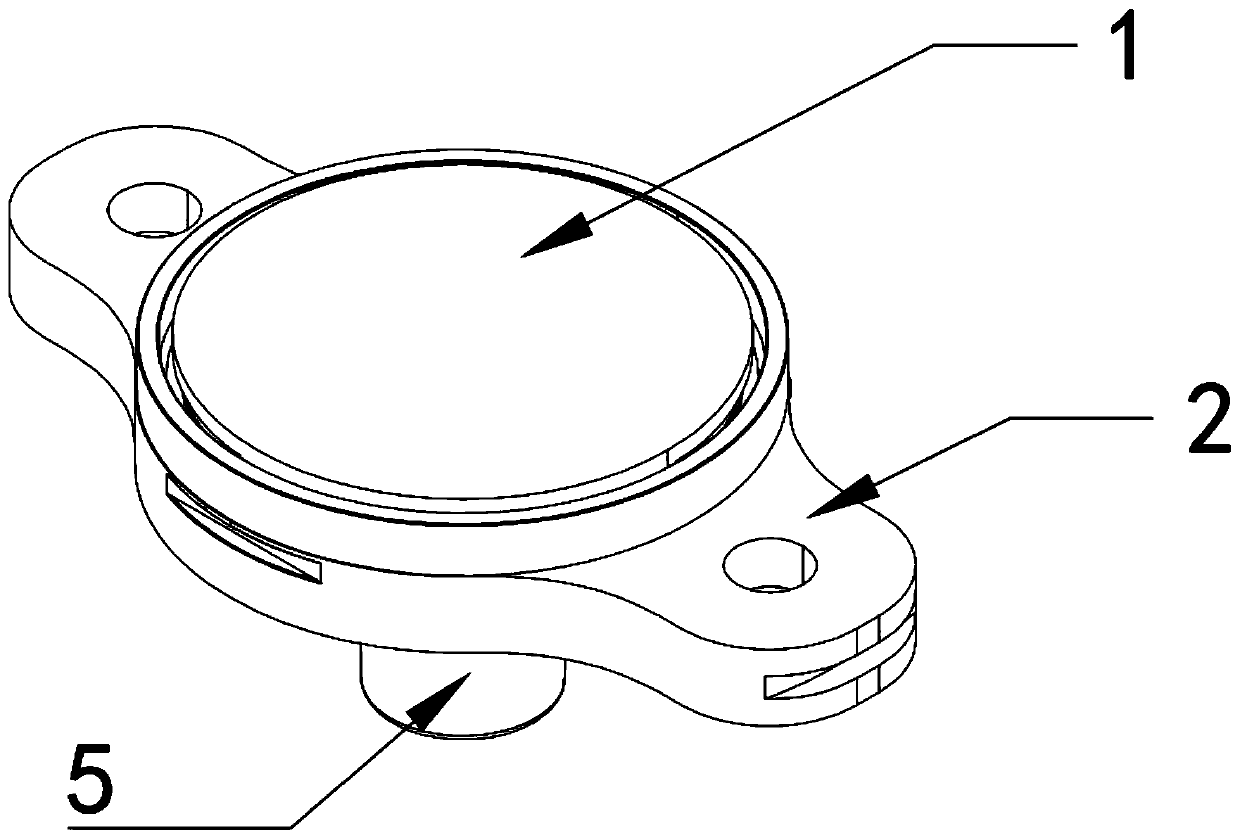

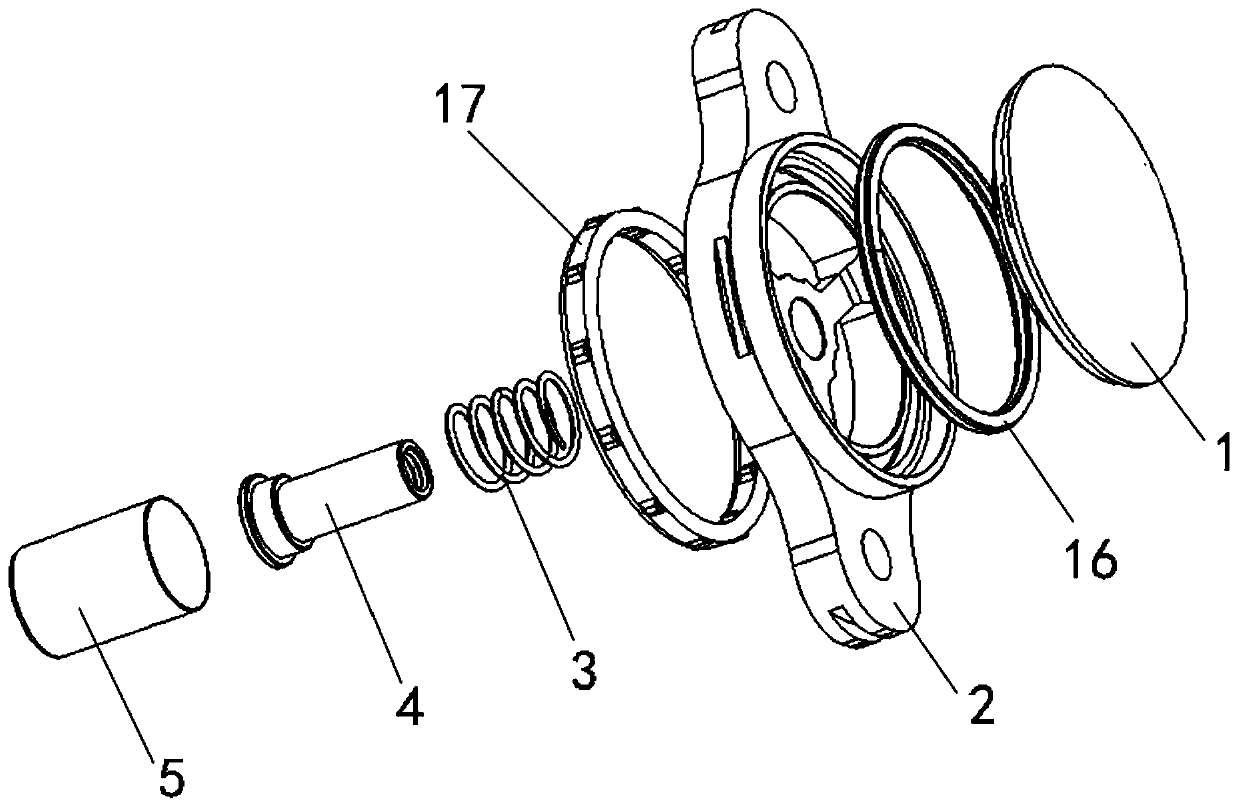

[0047] Embodiment 1: see Figure 1 to Figure 6 , an anti-clogging anti-explosion valve provided in this embodiment, which includes a piston 1, a valve body 2, a spring 3, and a connection that passes through the spring 3 and the valve body 2 in turn and is connected to the piston 1. The shaft 4 is provided with a first through hole through the connecting shaft 4, and a protective cover 5 is installed on the valve body 2 around the outside of the spring 3, and the end of the protective cover 5 away from the valve body 2 is The sealing end; specifically, the piston 1 and the connecting shaft 4 are threadedly connected, and the protective cover 5 is installed on the valve body 2 by means of interference fit or pressure riveting connection. According to the requirements of different explosion-proof valve products , flexible selection of the protective cover 5 of different dimensions, since the spring 3 and the connecting shaft 4 are included in the protective cover 5, the protecti...

Embodiment 2

[0068] Example 2: see Figure 7, the content of this embodiment is roughly similar to that of Embodiment 1, the difference is that the protective cover 5 is also provided with a flange 52, and the valve body 2 is provided with a flange fixing protrusion corresponding to the flange 52; After the protective cover 5 is installed on the valve body 2, the flange fixing protrusion fixes and presses the flange 52 by means of pressure riveting, so as to prevent the protective cover 5 from rotating and falling off, and effectively improve the firmness of the installation , low processing cost, and convenient for industrialized mass production.

Embodiment 3

[0069] Embodiment 3: see Figure 8 , the content of this embodiment is roughly similar to that of Embodiment 1, the difference is that there are four installation parts 6 in total, and the four installation parts 6 are respectively extended and arranged on the outside of the valve body 2 at intervals, and An annular airtight tooling groove 7 is arranged on the upper ring of the valve body 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com