Quick propeller mounting mechanism for multi-rotor aircraft

A technology of multi-rotor aircraft and mounting mechanism, which is applied in the direction of rotorcraft, aircraft, unmanned aircraft, etc., can solve the problems of motor output shaft damage, low assembly stability, large volume and weight of fixed base, etc., and achieve reduction The effect of difficulty of operation, reduction of volume and weight, and improvement of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

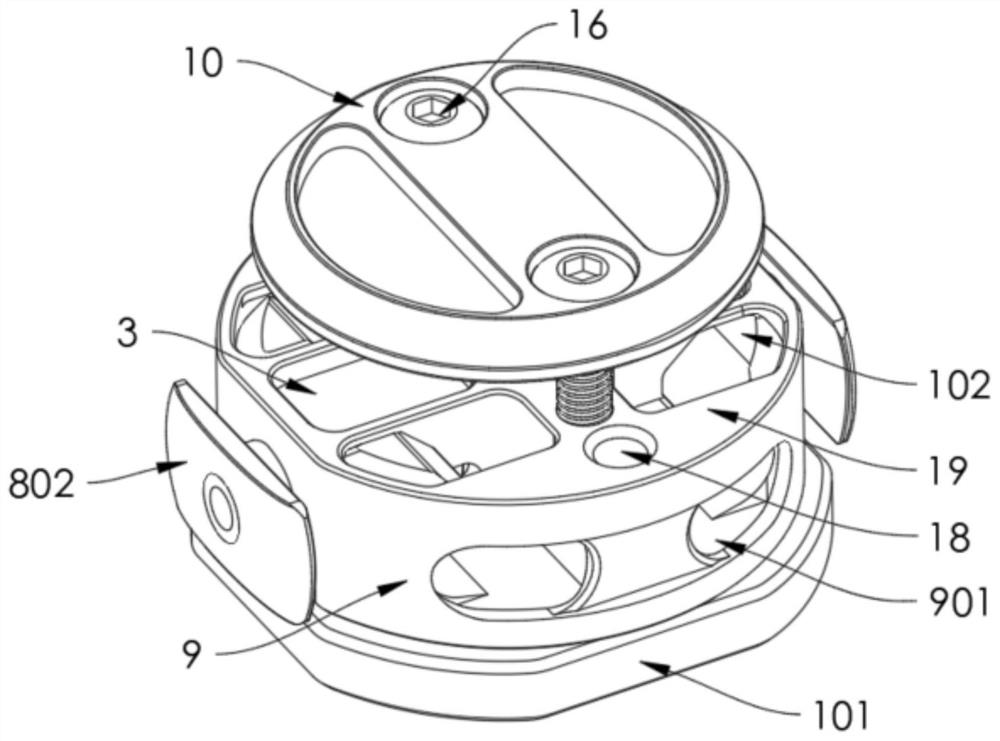

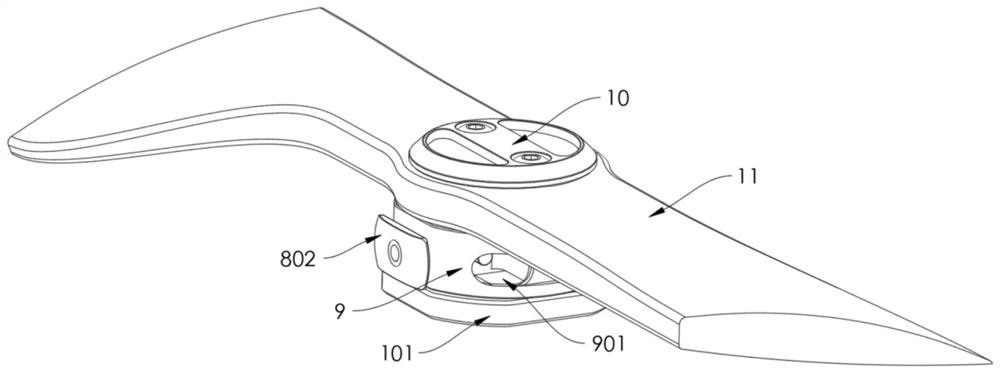

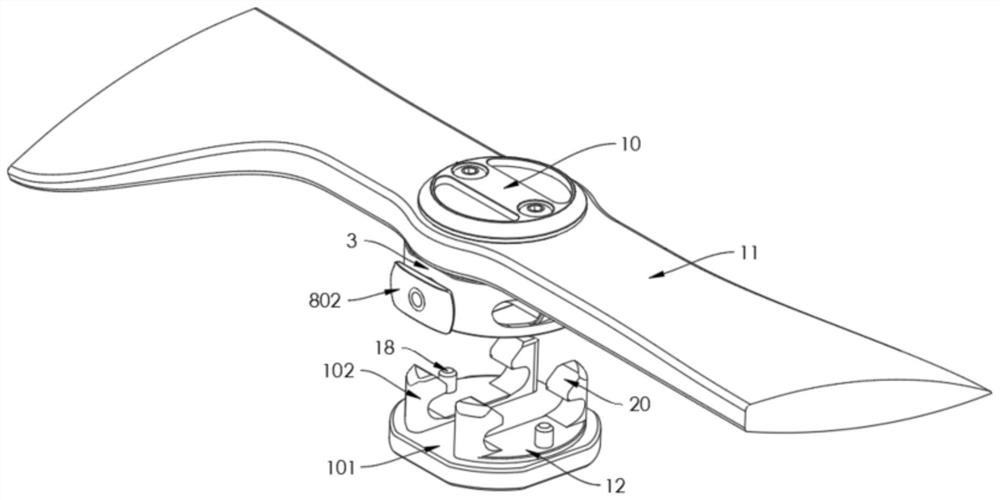

[0042] refer to Figure 1-8 , a fast propeller installation mechanism for a multi-rotor aircraft, comprising

[0043] The fixed base 1 includes a base plate 101 fixedly connected to the output shaft end of the motor and two sets of fasteners 102 arranged on the base plate 101, and the opposite sides of the same set of fasteners 102 are respectively provided with corresponding fastening grooves 2;

[0044] The connecting piece 3 is detachably mounted on the fixed base 1, and the connecting piece 3 is respectively provided with a corresponding chute 4 at a position corresponding to the buckling groove 2, and the connecting piece 3 is mounted on the chute The outer sides of 4 are respectively provided with corresponding mounting holes 5, and corresponding faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com