Chemical fertilizer formula for medicinal material planting

A technology of chemical fertilizers and medicinal materials, which is applied in the field of chemical fertilizer formulations for medicinal planting and its processing equipment, which can solve the problems of destroying the agricultural ecological environment, poor particle screening effect, inconvenient adjustment and treatment, etc., to reduce environmental impact and soil damage , Good controlled release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] like figure 1 As shown, a chemical fertilizer for medicinal planting is composed of the following ingredients in parts by weight: 28-39 parts of vegetable cakes, 20-32 parts of fish pond mud, 9-12 parts of rice straw, and 23-32 parts of chicken manure. 28 parts, plant ash 12-18 parts, potassium dihydrogen phosphate 7-12 parts, urea 9-15 parts, trace element fertilizer 1-3 parts, calcium magnesium phosphate fertilizer 15-25 parts, potassium sulfate 5-10 parts, humus 12- 18 parts and deodorant 4.5-12 parts.

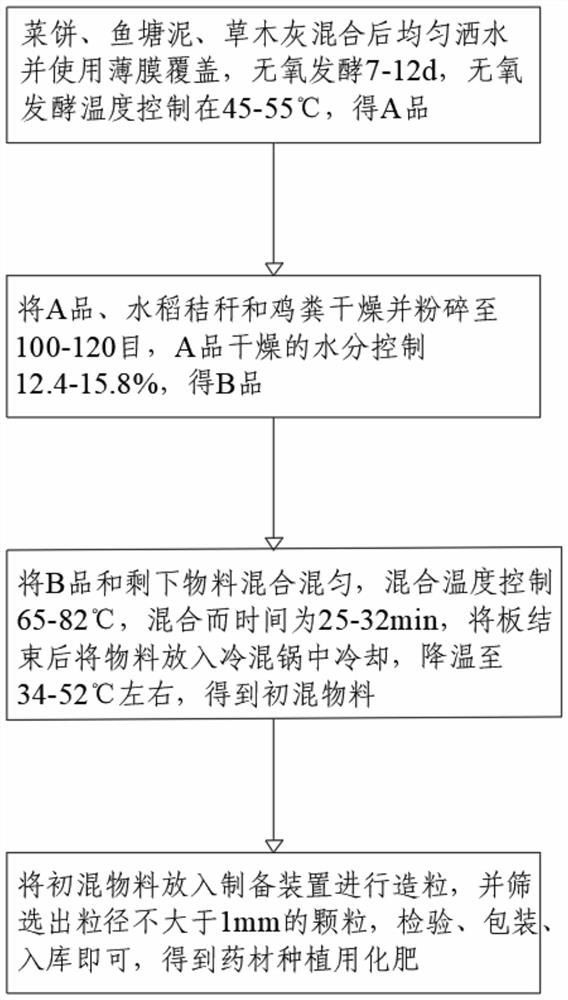

[0046] A preparation process of a chemical fertilizer for medicinal material planting, the preparation process steps are as follows:

[0047] Step 1. After mixing the vegetable cake, fish pond mud and plant ash, evenly sprinkle water and cover with a film, anaerobic fermentation for 7-12 days, and the anaerobic fermentation temperature is controlled at 45-55°C to obtain product A;

[0048] Step 2, drying and pulverizing product A, rice straw and chicken manure to 1...

Embodiment 2

[0053] Embodiment 2 is a further improvement to Embodiment 1.

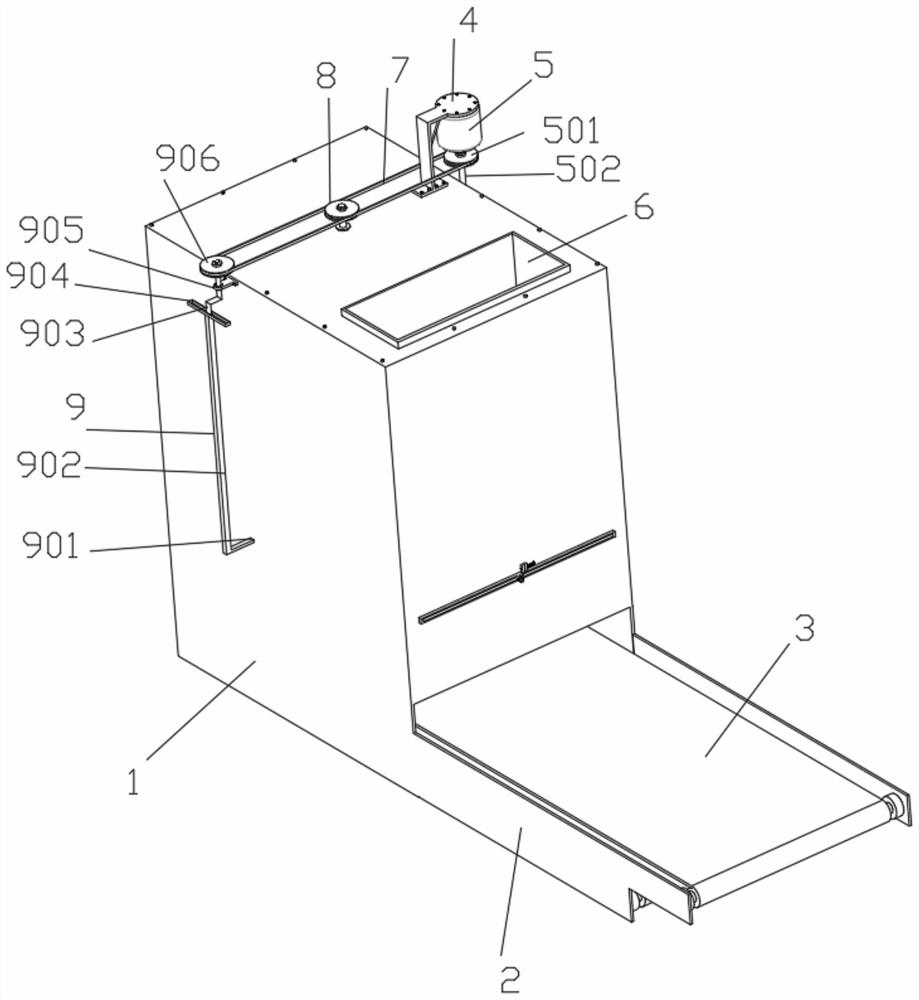

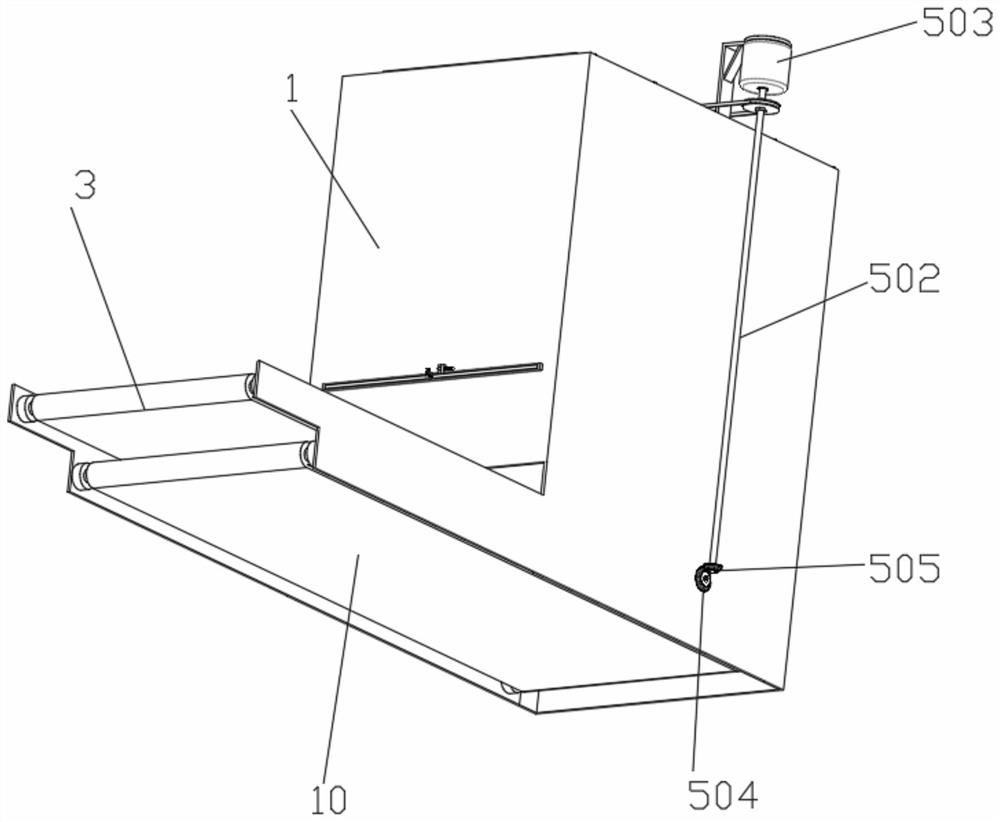

[0054] like figure 2 , 3 , 4, 5, 7, 8, 9, 10 and 11 show a preparation device for chemical fertilizers for planting medicinal materials, including a main body 1, a horizontal plate 2, a large material conveyor belt 3 and a blanking conveyor belt 10, the top of the main body 1 is straight The hole is fixedly connected with a silo 6 for storing chemical fertilizer raw materials, and the silo 6 is connected with a pressing structure 8. The pressing structure 8 includes a second pulley 801, a third rotating shaft 802, an L-shaped pressing plate 803, a reciprocating thread groove 804, and a feeder. The material hole 805 and the straight tube 806, the top of the main body 1 is rotatably connected with a third rotating shaft 802 through a fixedly connected bearing, the lower end of the third rotating shaft 802 is provided with a reciprocating thread groove 804, and the third rotating shaft 802 is threaded with a L Sha...

Embodiment 3

[0058] Embodiment 3 is a further improvement to Embodiment 1.

[0059] like figure 2 , 7As shown in , 11, the main body 1 and the straight cylinder 806 are connected with a granulation structure 11 used in conjunction with the L-shaped pressing plate 803. The granulation structure 11 includes an outer plate 1101, a first circular plate 1102, a first spring 1103, and a first connecting block 1104 , the second connection block 1105, the insertion rod 1106, the second circular plate 1107, the second spring 1108, the slide bar 1109, the upper tooth plate 1110, the lower tooth plate 1111, the middle plate 1112, the horizontal hole 1113, the granulation hole 1114 and the first Three connecting blocks 1115, the top of the outer end of the outer plate 1101 is fixedly connected with the first connecting block 1104, the right side wall of the first connecting block 1104 is fixedly connected with the first spring 1103, and the right side wall of the first spring 1103 is fixedly connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com