Preparation method of high-reactivity nano aluminum/copper oxide microspheres

A high-reactivity, nano-aluminum technology, applied in the direction of copper oxide/copper hydroxide, nanotechnology, metal processing equipment, etc., can solve the problem of less research on micro-nano composite energetic materials, and can not effectively improve the easy oxidation of nano-aluminum and the inability to form Problems such as core-shell structure achieve the effect of shortening the mass transfer distance, high sphericity, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

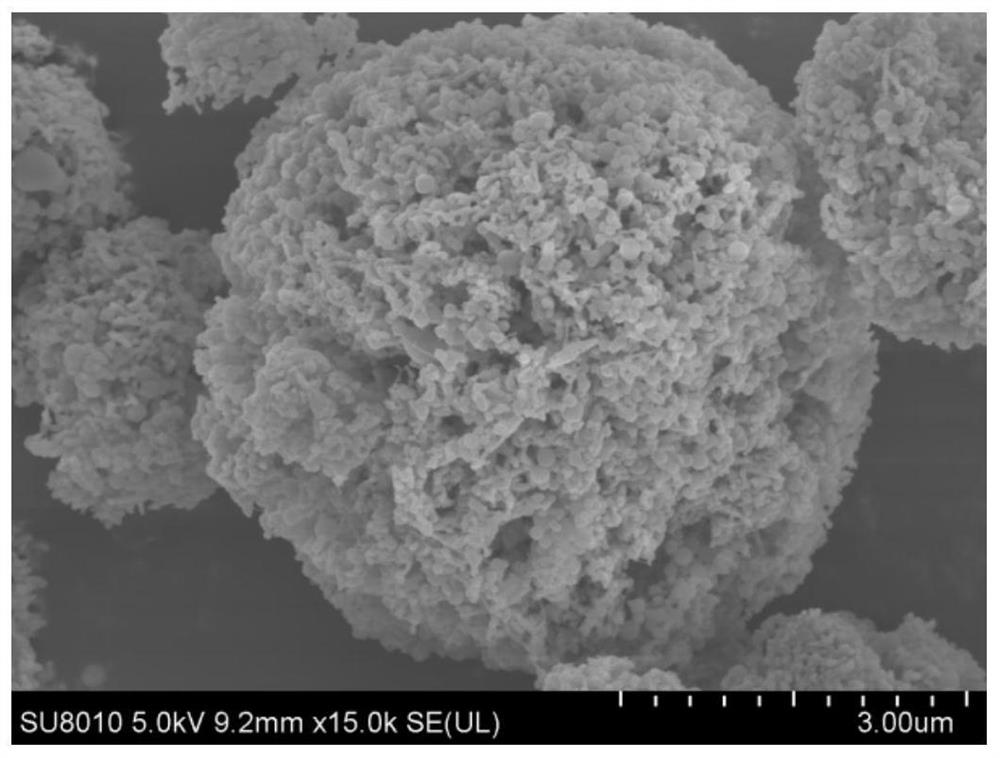

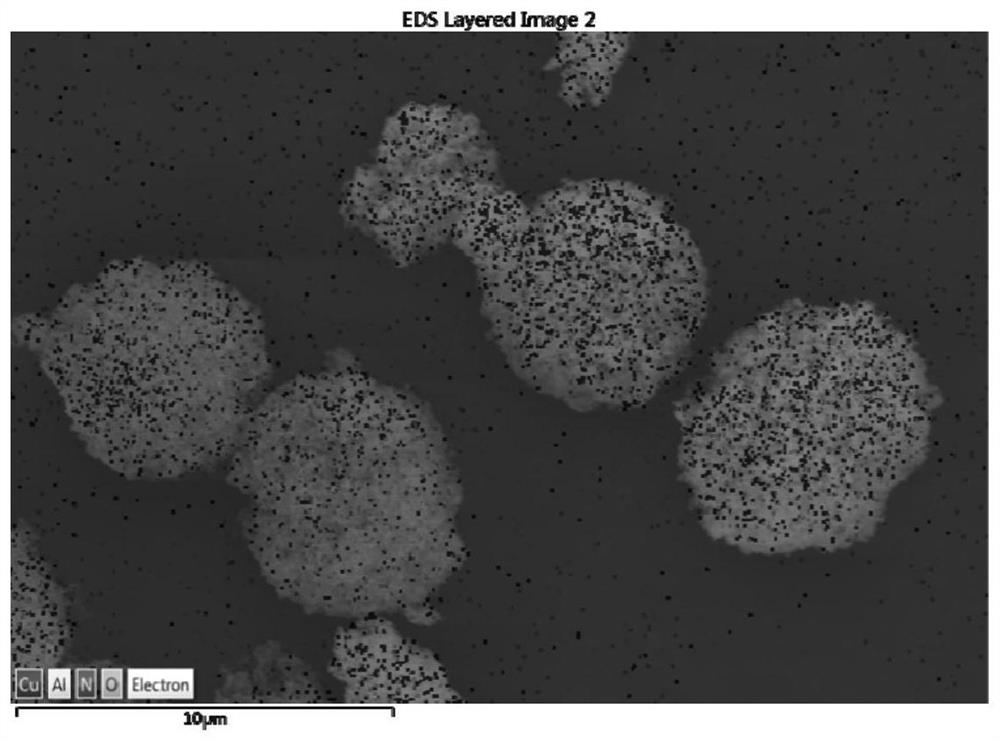

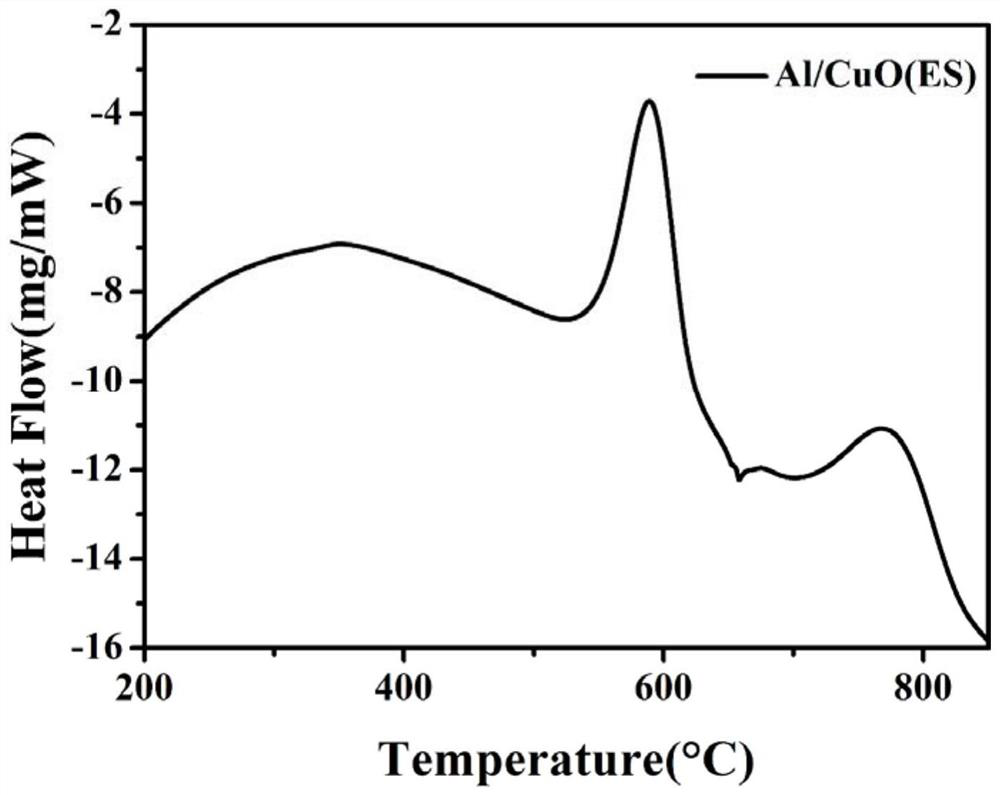

[0029] Weigh 200mg of nano-aluminum powder, 600mg of copper oxide, and 6mg and 18mg of nitrocellulose at room temperature, measure 2mL and 3mL of solvent acetone, and place the weighed nitrocellulose into a good amount of acetone at 25°C, and stir magnetically The speed is 500rpm, so that the nitrocellulose is completely dissolved, the weighed nano aluminum powder and copper oxide are put into the nitrocellulose solution, ultrasonicated at an ultrasonic frequency of 50kHZ for one hour, and then magnetically stirred for 24 hours before use. Quickly put the obtained aluminum powder solution into a 10mL plastic syringe, quickly put the copper oxide solution into a 5mL syringe, and replace the 10mL plastic syringe with a 21G flat apex metal coaxial needle, and at the same time, put the copper oxide solution into the outer tube, and then Install the syringe on the propulsion pump in the electrostatic spray device with an ambient temperature of 25°C, set the flow rate of the inner tu...

Embodiment 2

[0031]Weigh 200mg of nano-aluminum powder, 600mg of copper oxide and 12mg and 36mg of nitrocellulose at room temperature, measure 2mL and 3mL of solvent acetone, put the weighed nitrocellulose into a good amount of acetone at 25°C, and stir magnetically The speed is 500rpm, so that the nitrocellulose is completely dissolved, the weighed nano aluminum powder and copper oxide are put into the nitrocellulose solution, ultrasonicated at an ultrasonic frequency of 50kHZ for one hour, and then magnetically stirred for 24 hours before use. Quickly put the obtained aluminum powder solution into a 10mL plastic syringe, quickly put the copper oxide solution into a 5mL syringe, and replace the 10mL plastic syringe with a 21G flat apex metal coaxial needle, and at the same time, put the copper oxide solution into the outer tube, and then Install the syringe on the propulsion pump in the electrostatic spray device with an ambient temperature of 25°C, set the flow rate of the inner tube prop...

Embodiment 3

[0033] Weigh 200mg of nano-aluminum powder, 800mg of copper oxide and 12mg and 36mg of nitrocellulose at room temperature, measure 2mL and 3mL of solvent acetone, put the weighed nitrocellulose into a good amount of acetone at 25°C, and stir magnetically The speed is 500rpm, so that the nitrocellulose is completely dissolved, the weighed nano aluminum powder and copper oxide are put into the nitrocellulose solution, ultrasonicated at an ultrasonic frequency of 50kHZ for one hour, and then magnetically stirred for 24 hours before use. Quickly put the obtained aluminum powder solution into a 10mL plastic syringe, quickly put the copper oxide solution into a 5mL syringe, and replace the 10mL plastic syringe with a 21G flat apex metal coaxial needle, and at the same time, put the copper oxide solution into the outer tube, and then Install the syringe on the propulsion pump in the electrostatic spray device with an ambient temperature of 25°C, set the flow rate of the inner tube pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com