Straight pipe four-direction multi-hole punching machine

A multi-hole punching and four-direction technology, which is applied in positioning devices, cleaning methods and tools, chemical instruments and methods, etc., can solve the problem of insufficient compactness of the structure of the jacking device and the punching machine, large equipment footprint, and workpiece positioning. Difficulty and other problems, to avoid manual operation accidents, long service life of equipment, and less space occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below, examples of which are shown in the accompanying drawings, and the embodiments described below by referring to the accompanying drawings are exemplary and are intended to explain the present invention so that the technical solutions of the present invention It is easier to understand and grasp, but cannot be construed as a limitation to the present invention.

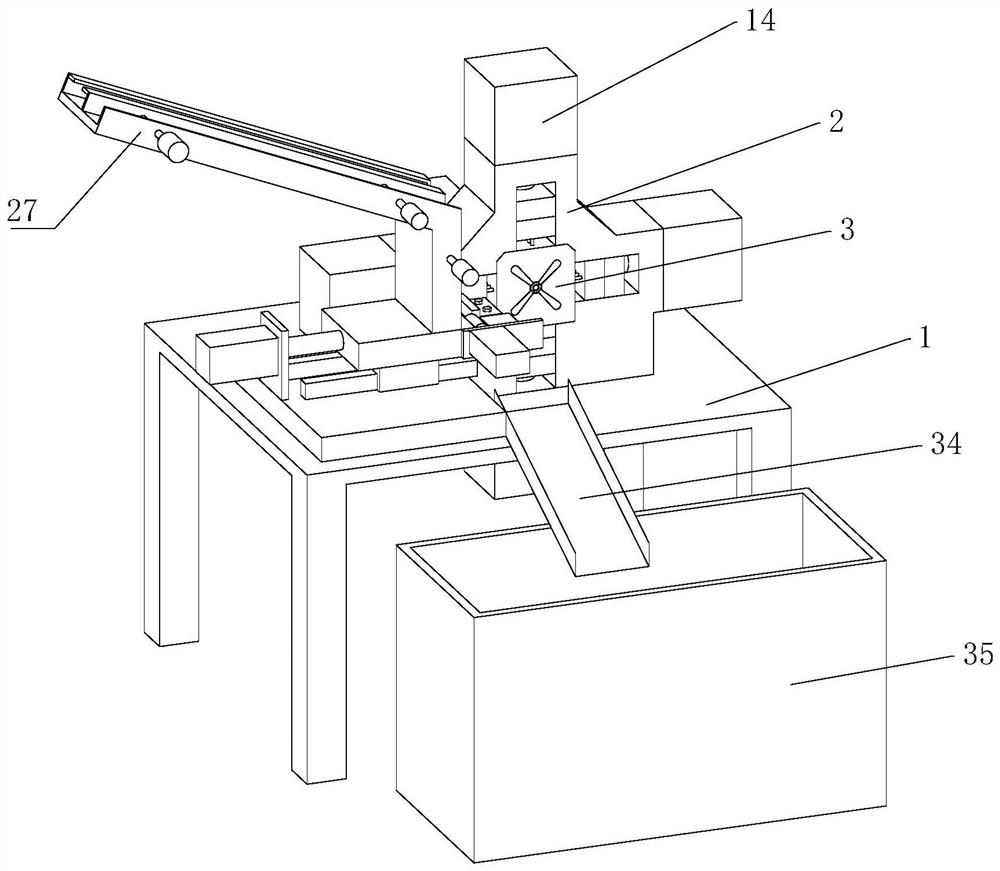

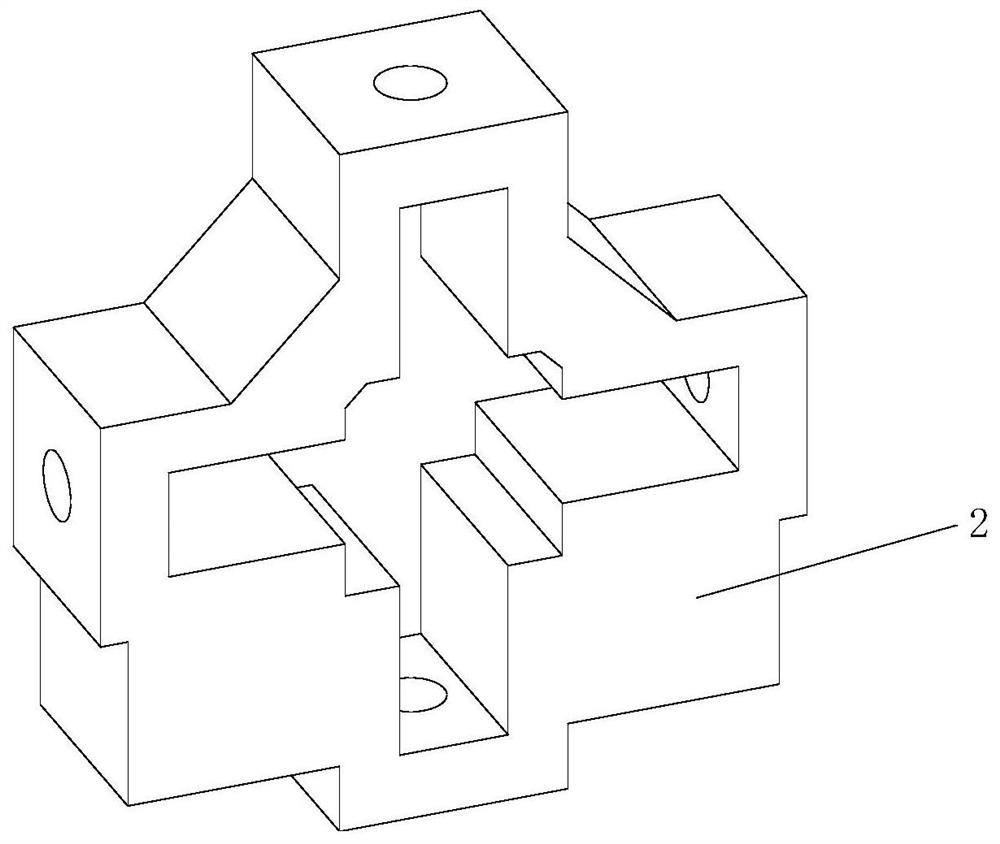

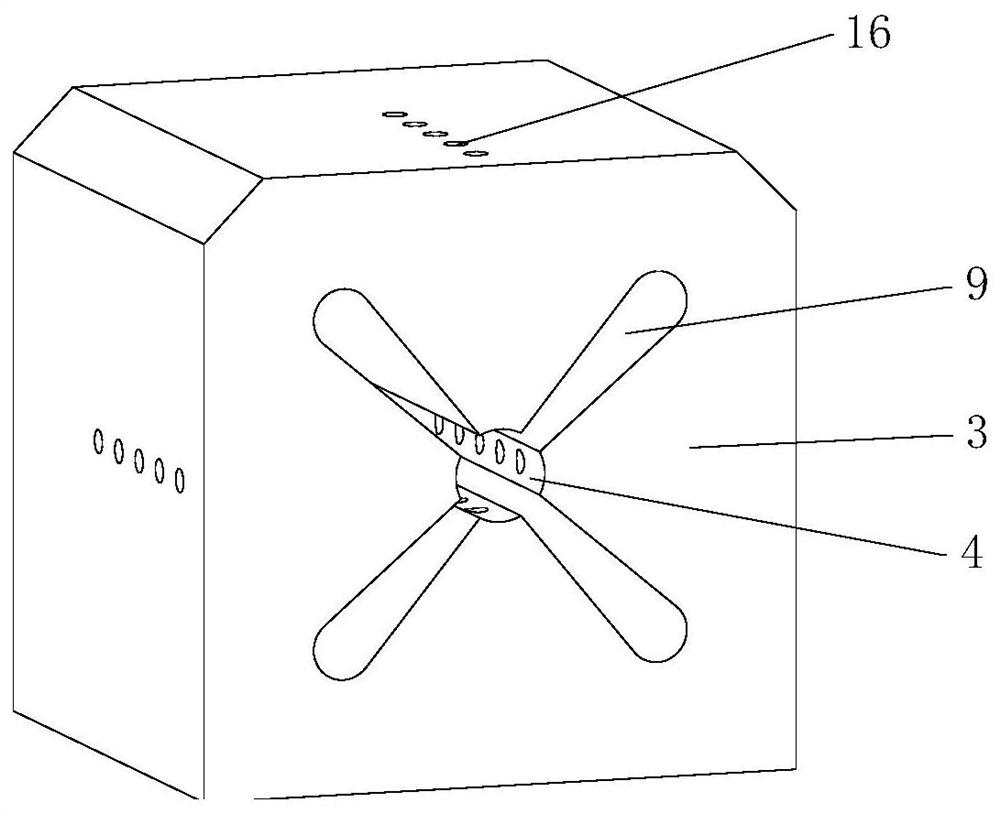

[0031] refer to Figure 1-8 As shown, the present invention provides a technical solution: a straight tube four-direction multi-hole punching machine, including a frame 1, on which a punching frame 2 is arranged, and the punching frame 2 is in the shape of a "ten", punching The center of the frame 2 is fixed with a mold shell 3, and the mold shell 3 is provided with a mold hole 4 that runs through the front and back. The diameter of the mold hole 4 is slightly larger than the diameter of the workpiece, so the workpiece can be placed in the mold ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com