Scrap recovery treatment device for aluminum alloy machining

A technology for recycling and processing aluminum alloys, applied in the field of aluminum alloy processing, can solve the problems of wasting time, inconvenient to distinguish, prone to errors, etc. The effect of the squeeze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

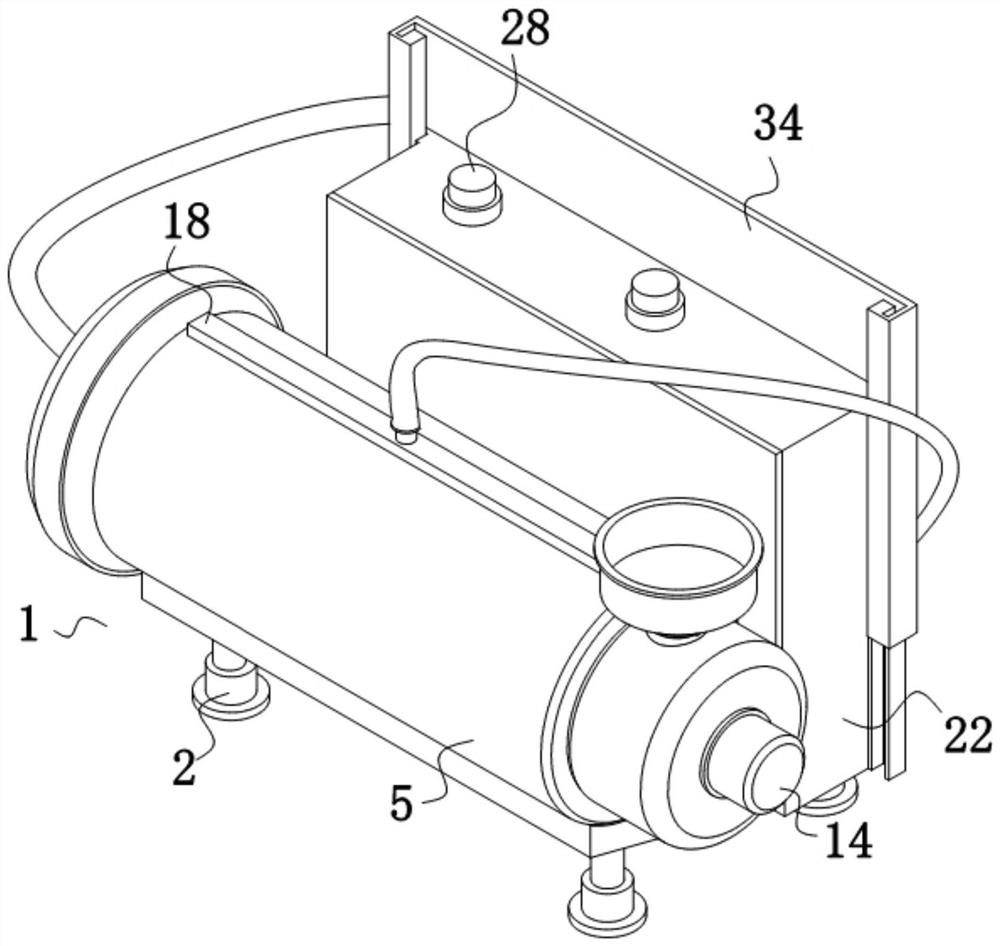

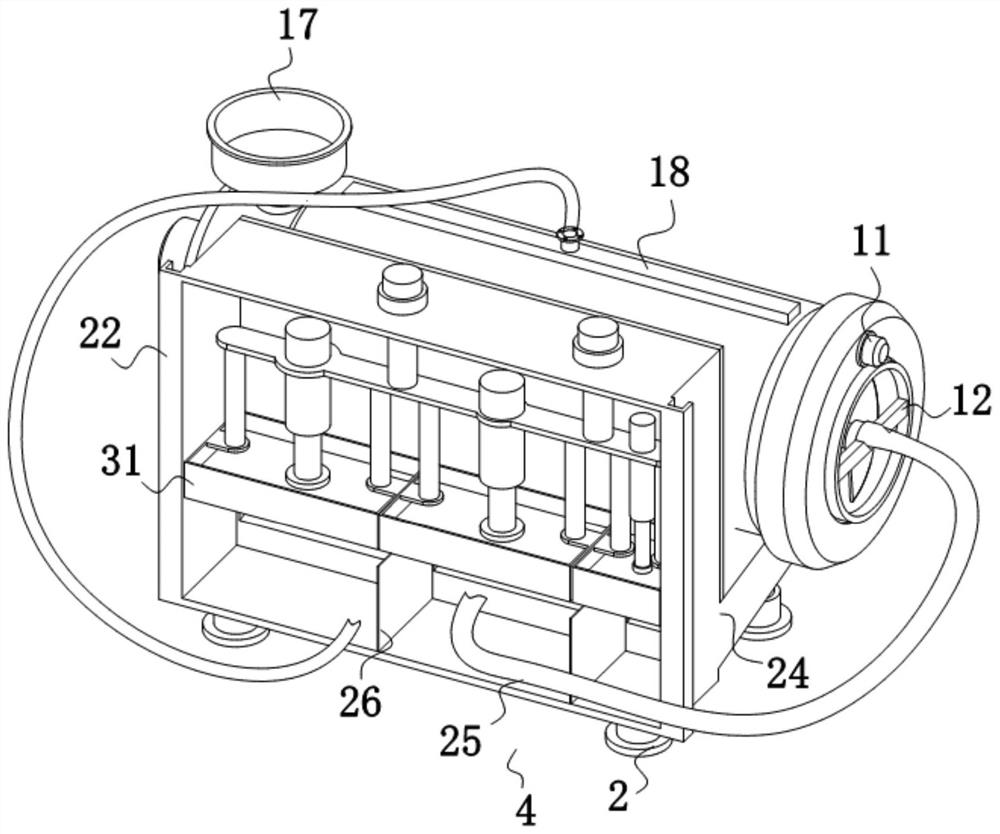

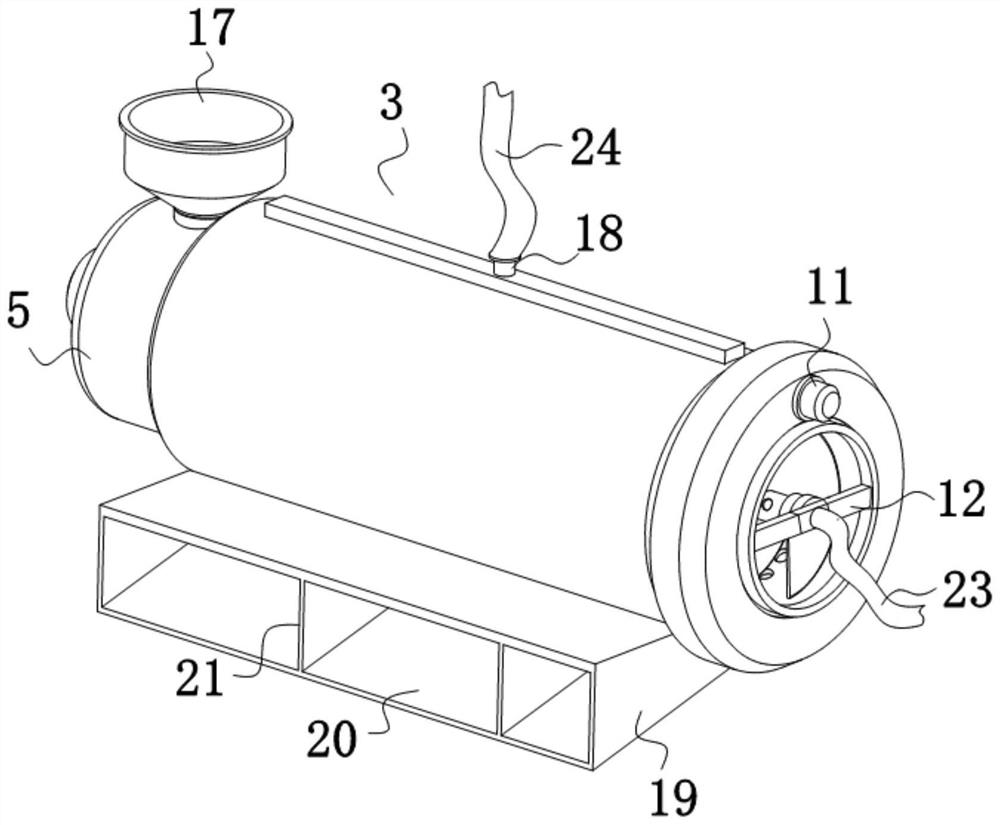

[0030] like Figure 1-Figure 6 As shown, a waste recycling and processing device for aluminum alloy processing includes a device body 1 , a plurality of symmetrically distributed legs 2 are provided at the bottom of the device body 1 , and the device body 1 includes a screening mechanism 3 and a compression mechanism 4 .

[0031]The screening mechanism 3 includes a screening housing 5, the inside of the screening housing 5 is rotatably connected with a sieve cylinder 6, the top of the screening housing 5 is provided with a feed hopper 17, and the discharge port of the feed hopper 17 is arranged on the screen At one end of the cylinder 6, the aluminum alloy waste is put into the screening casing 5 along the feed hopper 17, and enters the screening cylinder 6 from the screening casing 5. The screening cylinder 6 is a hollow structure with openings at both ends, and the hollow structure can be realized in the The material is fed and discharged in the sieve cylinder 6, and the sie...

no. 2 example

[0036] Based on the waste recycling and processing device for aluminum alloy processing provided by the first embodiment, when the device is in use, the start and end time of the compression assembly 27 and the control of the compaction degree of the waste in each compression chamber 25 are relatively backward, and there is no detailed The control range depends entirely on the manual observation of the operator, and the device uses the centrifugal force generated by the auxiliary motor 11 to drive the sieve cylinder 6 to rotate to screen the internal aluminum alloy waste. The optimal speed required for screening is also different, especially after the device is divided into the first sieve area 7, the second sieve area 8 and the third sieve area 9, the screen cylinders required for each sieve area 6 optimal rotating speeds are just different, similarly, when the main drive motor 14 screw blade 16 rotates and drives the aluminum alloy scrap to feed, because the length setting of...

no. 3 example

[0040] Based on the waste recycling and processing device for aluminum alloy processing provided in the second embodiment, the aluminum alloy waste is screened through the screen holes due to the rotation of the screen drum 6 itself, and the rotation of the screw blade 16 feeds the waste. Therefore, in the actual use process, it is inevitable that waste materials will be stuck in the screen holes and attached to the outer surface of the screw blade 16. If the waste materials are not removed as soon as possible, not only will the batch of waste materials not be fully screened, but it will also affect Sieve the next batch of waste materials, and at the same time, due to the high-speed screening of the sieve cylinder 6, the sieved waste materials are not smoothly discharged in the material guide chamber 20, resulting in blockage, and a large amount of sieved waste materials are accumulated in the screening housing 5. The bottom will affect the subsequent screening work. In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com