Amine/ammonia evaporation and absorption integrated device and application method thereof

An application method, ammonia evaporation technology, applied in chemical instruments and methods, evaporation, separation methods, etc., can solve the problems of high energy consumption, difficult water balance, low efficiency, etc., and achieve energy consumption reduction, simple operation, and production mode flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

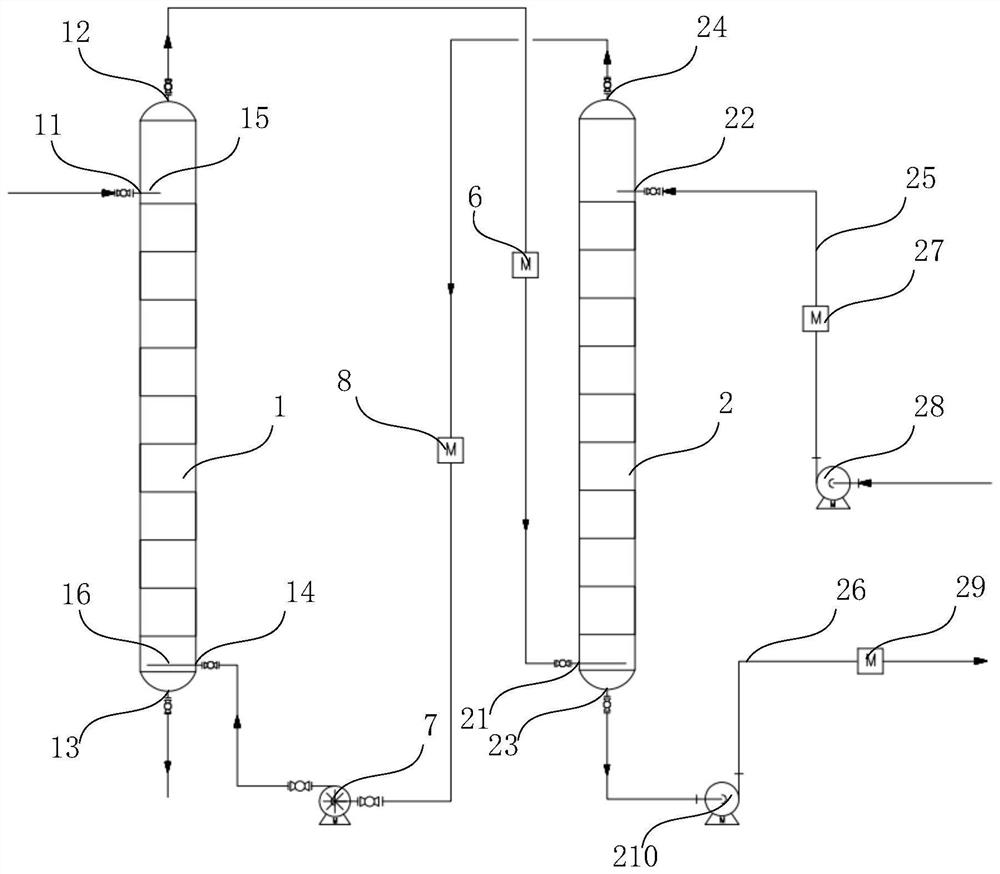

Embodiment 1

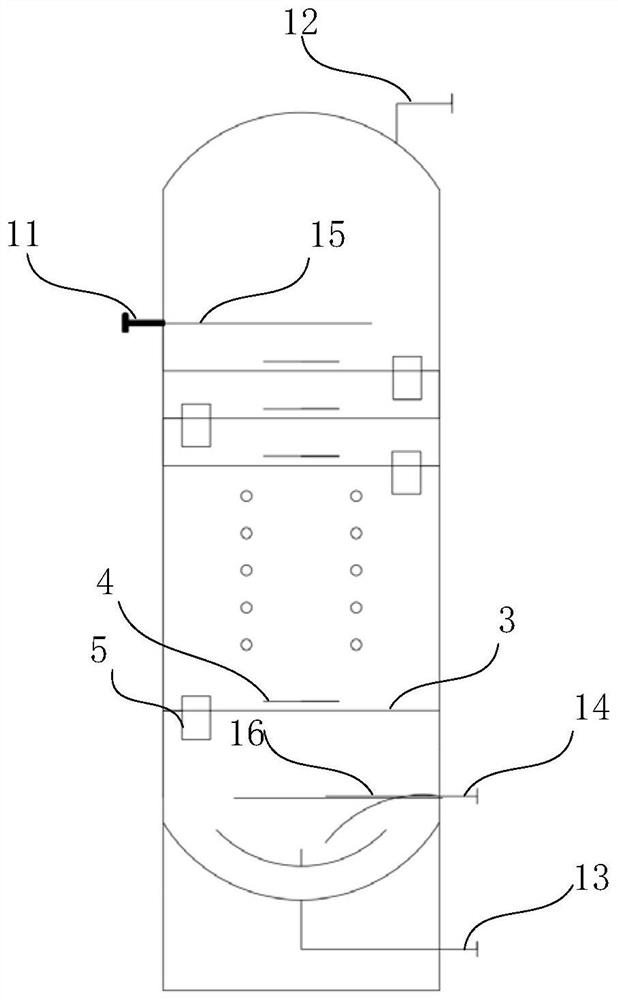

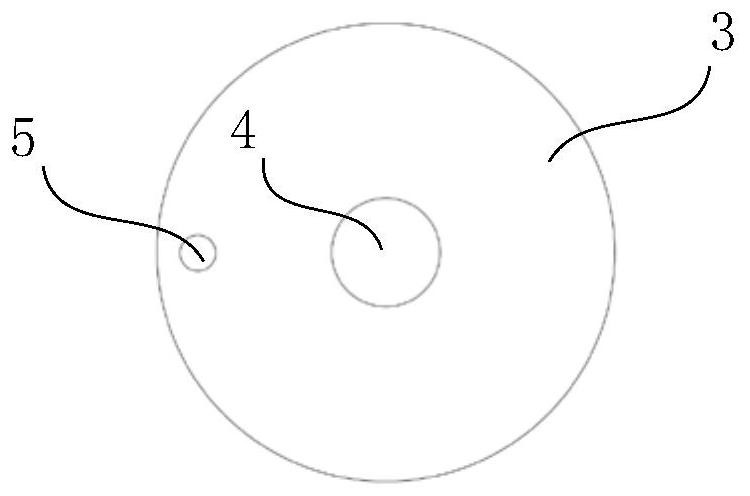

[0111] (1) will contain Ca(OH) 2 and Mg(OH) 2 The mixed slurry and the diethylamine acetate solution are fully mixed in the raw material premix tank, the concentration of calcium hydroxide in the slurry is 12wt%, the concentration of magnesium hydroxide is 8.1wt%, and the concentration of diethylamine acetate solution is About 25wt%; when feeding, control the molar ratio of hydroxide corresponding to calcium hydroxide to diethylamine to be 1:0.8;

[0112] (2) Use a pump to add the slurry in the premixing tank in step 1 to the ammonia distillation tower 1 through the feed port 11, control the temperature of the ammonia distillation tower to 25°C, and react the obtained calcium acetate solution and diethylamine steam, acetic acid Calcium solution and unreacted magnesium hydroxide slurry are discharged from the first material outlet 13 of the ammonia distillation tower, and the efficiency of ammonia distillation reaches 95% within two hours.

[0113] (3) The diethylamine obtain...

Embodiment 2

[0117] (1) will contain Ca(OH) 2 The slurry and the piperidine hydrochloride solution are fully mixed in the raw material premixing tank, wherein the concentration of calcium hydroxide in the slurry is 20wt%, and the concentration of the piperidine hydrochloride solution is about 30wt%; when feeding, control the hydrogen The molar ratio of the corresponding hydroxide and piperidinium ions in calcium oxide is 1:1;

[0118] (2) Use a pump to add the slurry in the premixing tank in step 1 to the ammonia distillation tower 1 through the feed port 11, control the temperature of the ammonia distillation tower to 90°C, and react the calcium chloride solution and piperidine vapor, chlorine Calcium solution is discharged from the first material outlet 13 of the ammonia distillation tower, and the ammonia distillation efficiency reaches 98% in one hour.

[0119] (3) The piperidine vapor that step 2) obtains is driven by the recycle gas and enters the 20wt% magnesium chloride that enter...

Embodiment 3

[0122] (1) Fully mix the NaOH solution and the n-butylamine formate solution in the raw material premix tank, wherein the NaOH concentration in the slurry is 10wt%, and the n-butylamine formate solution concentration is about 20wt%; , control the molar ratio of the corresponding hydroxide in sodium hydroxide to n-butylammonium formate ion to be 1:1.2;

[0123] (2) Use a pump to add the slurry in the premixing tank in step 1 to the ammonia distillation tower 1 through the feed port 11, control the temperature of the ammonia distillation tower to 130°C, and react to obtain sodium formate solution and n-butylamine vapor, and the sodium formate solution is obtained by the distillation The first material outlet 13 of the amine tower is discharged, and the amine distillation efficiency reaches 99.5% in one hour.

[0124] (3) The n-butylamine steam obtained in step 2) is driven by the recycle gas and then discharged from the gas phase outlet 12 of the amine distillation tower and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com