Preparation method of FeNiP/C@MXene composite negative electrode material for lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as limitations, volume expansion, and low Coulombic efficiency, and achieve improved stability, extended battery life, and strong cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a FeNiP / C@MXene composite negative electrode material for lithium-ion batteries, the specific steps are as follows:

[0031] (1) Weigh 10 mg of ammonium ferrous sulfate and 42 mg of nickel acetylacetonate and dissolve them in 50 ml of ethanol, stir with strong magnetic force for 1 hour, then add the mixed solution until 90 mg of sodium polystyrene sulfonate and 100 mg of trimesis are dissolved. A solution of formic acid in 25ml of N,N-dimethylformamide was stirred with strong magnetic force for 2 hours, and the solution was put into a high-pressure reactor, reacted at 120°C, and kept at a constant temperature for 24 hours.

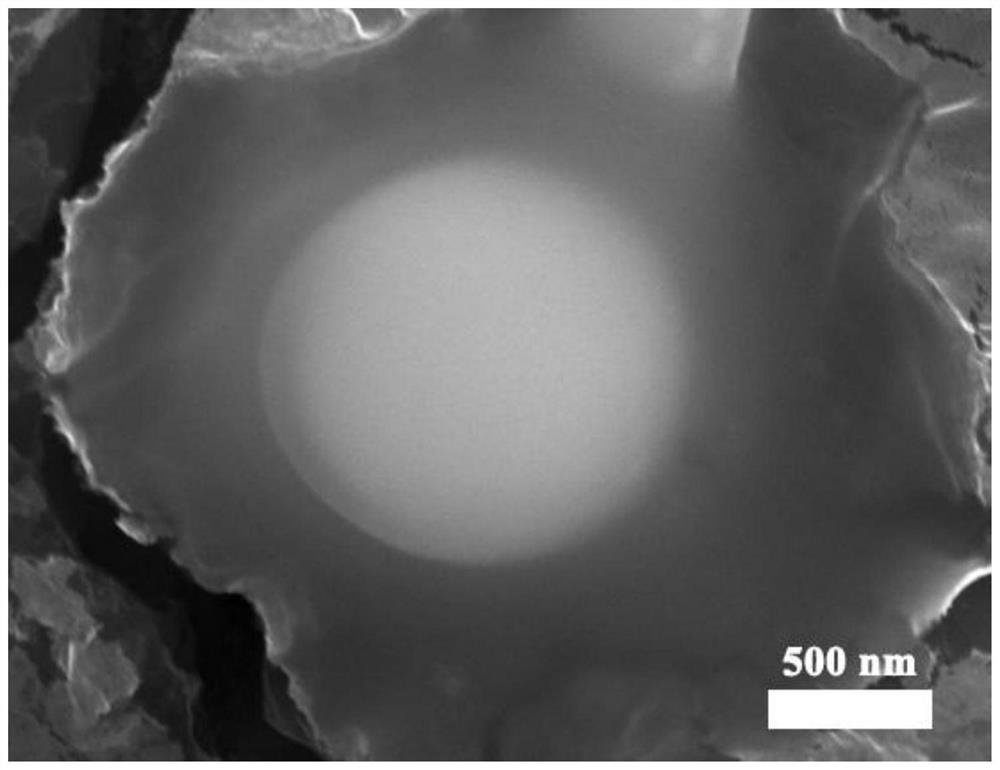

[0032] (2) Rinse the product in step (1) three times with ethanol, then centrifuge, and then vacuum-dry at 70°C for 12 hours to obtain a mixed metal-organic framework template Fe / Ni-MOF. The template is a porous hollow structure with a specific surface area of 270.1 m 2 / g.

[0033] (3) 50mg of Fe / Ni-MOF and 1mg of few-lay...

Embodiment 2

[0038] A method for preparing a FeNiP / C@MXene composite negative electrode material for lithium-ion batteries, the specific steps are as follows:

[0039](1) Weigh 35 mg of ammonium ferrous sulfate and 81 mg of nickel acetylacetonate and dissolve them in 50 ml of ethanol, stir with strong magnetic force for 2 hours, then add the mixed solution until 121 mg of sodium polystyrene sulfonate and 48 mg of cyclohexane disulfide are dissolved. A solution of formic acid in 50ml of N,N-dimethylformamide was stirred with strong magnetic force for 1.2h, and the solution was put into an autoclave, reacted at 150°C, and kept at a constant temperature for 36h.

[0040] (2) Rinse the product in step (1) three times with ethanol, then centrifuge, and then vacuum-dry at 70°C for 12 hours to obtain a mixed metal-organic framework template Fe / Ni-MOF. The template is a porous hollow structure with a specific surface area of 220.1 m 2 / g.

[0041] (3) Combine 50mg of Fe / Ni-MOF with 2mg of few-...

Embodiment 3

[0045] A method for preparing a FeNiP / C@MXene composite negative electrode material for lithium-ion batteries, the specific steps are as follows:

[0046] (1) Weigh 40 mg of ammonium ferrous sulfate and 20 mg of nickel acetylacetonate and dissolve them in 50 ml of ethanol, stir for 2.5 hours with strong magnetic force, then add the mixed solution until 80 mg of sodium dodecylsulfonate and 30 mg of p-benzene In a solution of dicarboxylic acid in 200ml of N,N-dimethylformamide, stir with strong magnetic force for 3h, put the solution into an autoclave, react at 170°C, and keep the temperature constant for 20h.

[0047] (2) Rinse the product in step (1) three times with ethanol, then centrifuge, and then vacuum-dry at 100°C for 8 hours to obtain a mixed metal-organic framework template Fe / Ni-MOF. The template is a porous hollow structure with a specific surface area of 151.6 m 2 / g.

[0048] (3) Combine 50mg of Fe / Ni-MOF with 5mg few-layer Mo 2 C mixed and stirred, aged for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com