Self-sealing type composite pipe seal and pipe fittings formed by same

A composite pipe and self-sealing technology, which is applied in the field of composite pipes, can solve the problems that steel-plastic composite pipes must be sealed, and cannot realize the assembly line operation of straight pipe end sealing in steel-plastic composite pipe extrusion production lines, and achieve sealing quality and strength. Improve the safety factor of pipeline use, avoid secondary reverse work, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

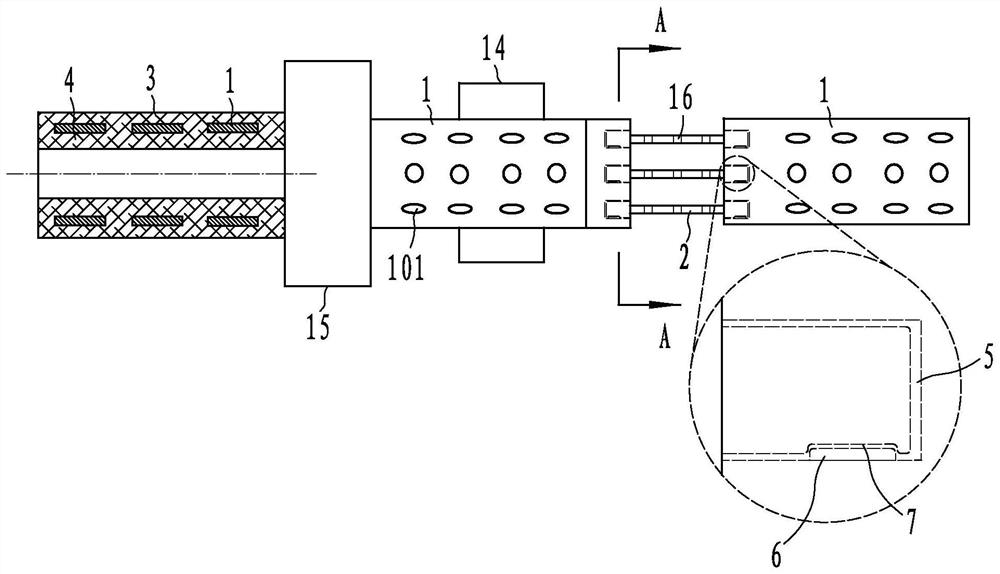

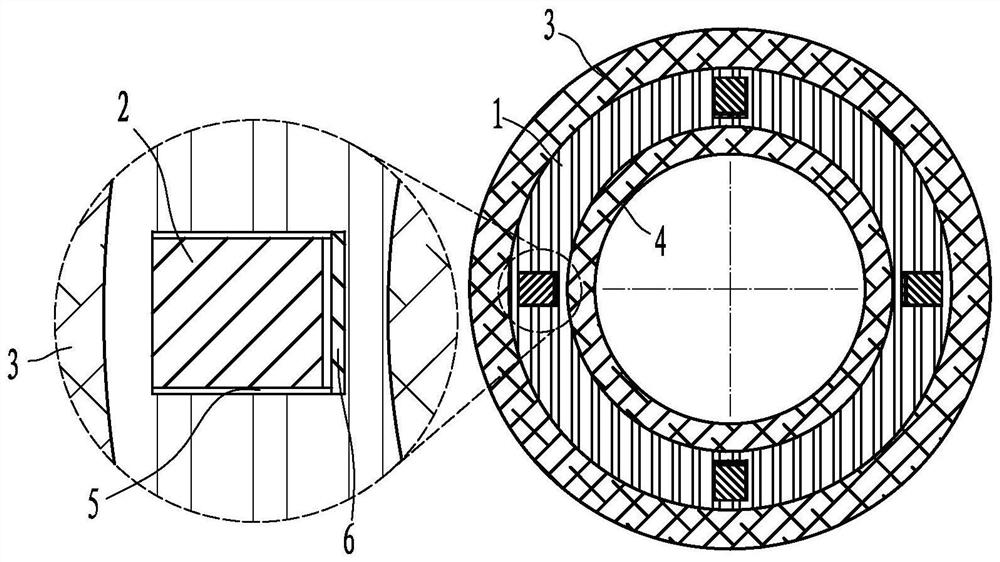

[0040] Embodiment 1: refer to figure 1 and figure 2

[0041]A plurality of slots 5 are arranged in the axial direction of the hole network pipe skeleton 1. The slots 5 are in the shape of a cuboid, and the bottom of the slots 5 is provided with a flange 6; There is a first groove 7 engaged with the flange 6; the production worker inserts the end of the connector 2 into the slot 5, and when the connector 2 touches the flange 6 at the bottom of the slot 5, an upward extrusion force is formed, and the The connecting piece 2 continues to be pushed into the slot 5 until the flange 6 of the slot 5 engages in the first groove 7 , thereby completing the fixing of the connecting piece 2 and the hole network pipe skeleton 1 . The slot 5 and the connecting piece 2 are simple in structure and easy to operate, and can significantly improve production efficiency.

[0042] The end of the connecting piece 2 and the flange 6 are provided with rounded corners. When the connecting piece 2 an...

Embodiment 2

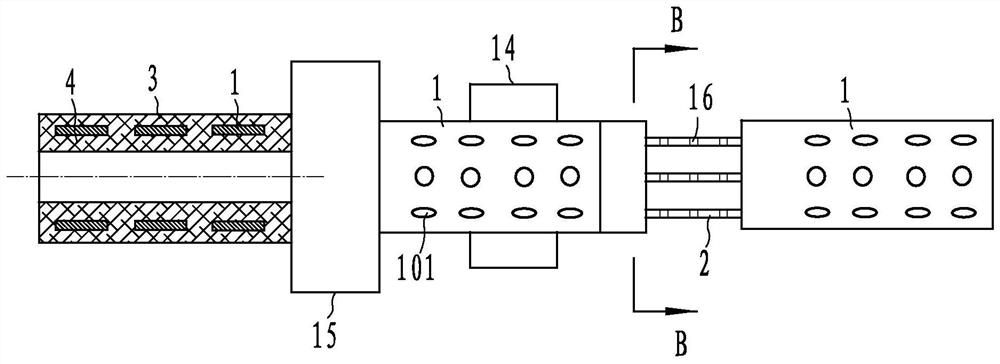

[0044] Embodiment 2: refer to image 3 and Figure 4

[0045] The slot 5 is arranged as an annular groove, and at least four annularly distributed embedding grooves 8 are arranged on the annular groove (four are specifically shown in the accompanying drawings), and each embedding groove 8 is provided with a boss 9, and in the hole network pipe The frame 1 radially corresponds to the boss 9 and the first screw hole 10 is provided on the boss 9; The first screw hole 10 is passed through the first screw hole 10 by the bolt 11 to realize the fixing of the hole network pipe frame 1 and the connecting piece 2 .

[0046] During specific assembly, the production worker can put the end of the connector 2 into the slot 5 as a whole to fit, and then use the bolt 11 to penetrate the hole network pipe skeleton 1, the connector 2 and the first screw hole 10 on the boss 9 to screw together, In this way, the overall fixation of the hole network pipe skeleton 1 and the connecting piece 2 is...

Embodiment 3

[0048] Embodiment 3: refer to Figure 5 and Figure 6

[0049] The slot 5 is set as a cylindrical groove, the two ends of the connecting piece 2 are set as a cylindrical body, and the hole network pipe skeleton 1 is provided with a first semi-annular groove 12 at the cylindrical insertion part at both ends of the connecting piece 2; the specific first semi-annular groove The thickness of 12 is 0.5-1.0mm greater than the diameter of the through hole 101 of the hole network pipe skeleton 1, the height of the bottom of the first semi-annular groove 12 is 30-40% of the total thickness of the hole-net composite pipe, and the bottom of the first semi-annular groove 12 is provided with a trapezoidal groove 13. The lower part of the trapezoidal groove 13 has a taper of 20-30 degrees to the bottom of the hole-net composite pipe; the structure of the first semi-annular groove 12 is convenient for the connector 2 to be inserted into the slot 5 as a whole.

[0050] More specifically, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com