Flat plate trolley and deslagging system

A technology of flat plate and trolley, which is applied to locomotives, railway derailment prevention, railway car body parts, etc., can solve the problems of long time and many processes, avoid secondary reverse transportation, improve slag removal efficiency, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

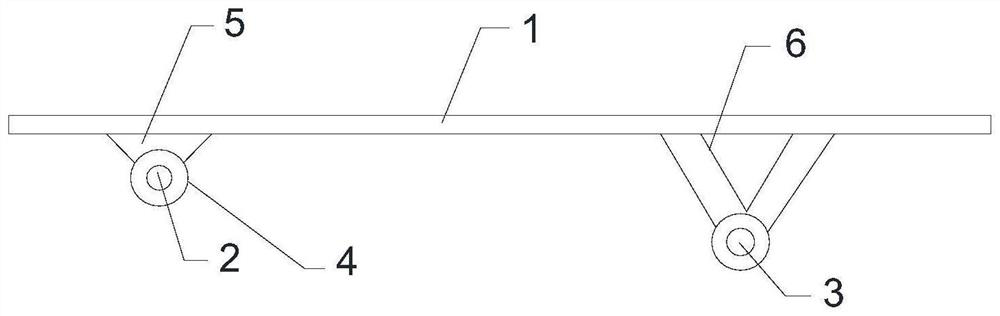

[0034] This embodiment provides a flatbed trolley, including a flatbed 1 , a front axle 2 , a rear axle 3 , a traveling wheel 4 , a front bracket 5 and two sets of rear brackets 6 . The bottoms of the front and rear ends of the flat plate 1 are respectively provided with a front wheel axle 2 and a rear wheel axle 3 , and the front wheel axle 2 and the rear wheel axle 3 are both provided with traveling wheels 4 . Specifically, the structural size of the flat plate 1 is determined according to the size of the selected dump truck, and the length of the dump truck is increased by 20 cm and the width is increased by 30 cm; 3) According to the weight of the flatbed trolley, the wheel axle of the flatbed trolley is made of φ80 round steel according to the calculation of the shear resistance of the axle.

[0035] The top of the front bracket 5 is rotatably mounted on the bottom of the flat plate 1 , and the rotation axis is parallel to the front axle 1 ; the front axle 2 is mounted on...

Embodiment 2

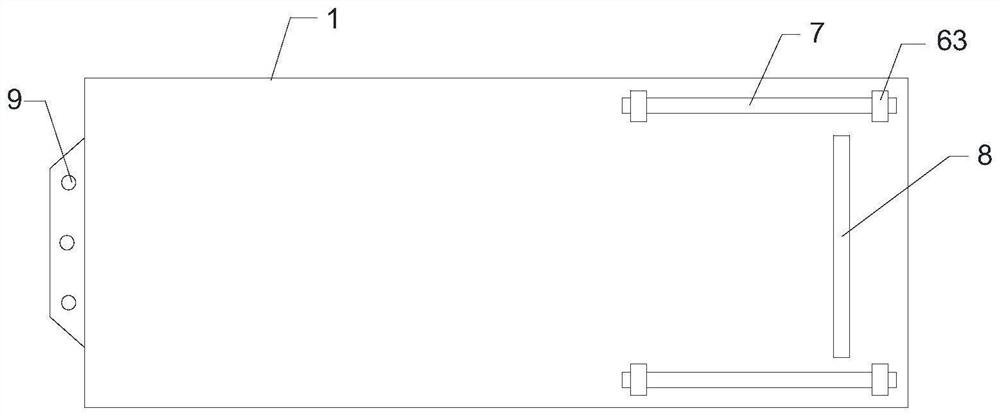

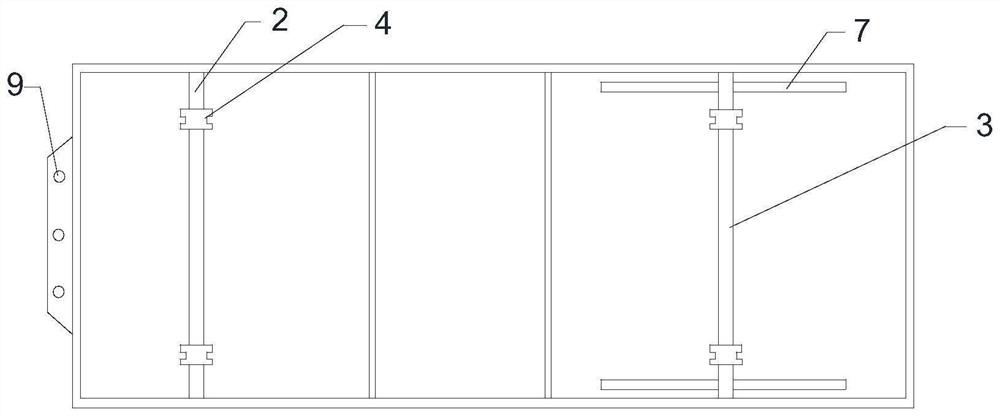

[0039] A further improvement is made on the basis of Embodiment 1. Both ends of the support beam I61 and the support beam II62 are provided with a shaft sleeve I64, and the shaft sleeve is rotatably sleeved on the rear wheel axle 2 . The other ends of the support beam I61 and the support beam II62 are provided with a bushing II65; the sliding block 63 is provided with a trunnion 66, and the bushing II65 is rotatably connected with the trunnion 66; 7. The chute 7 runs through the upper and lower sides of the plate 1 ; the slider 63 is connected to the shaft sleeve II65 by bolts, and the bolts pass through the chute 7 .

[0040] It also includes a cylinder, the fixed end of the cylinder is installed on the flat plate 1 , and the telescopic end of the cylinder 1 is connected with the slider 63 for driving the slider 63 to slide along the chute 7 . Each slider 63 is adapted to an air cylinder for controlling the sliding action of the slider 63 .

[0041] It also includes a rear b...

Embodiment 3

[0044] This embodiment provides a slag removal system, including a slag transporter 10, a winch 11 and a flatbed trolley provided in Embodiment 2;

[0045] During the slag transport operation in the inclined hole, the slag transporter 10 is placed on the flat plate 1, and the winch 11 is placed at the opening of the hole for releasing and pulling the traction rope 12, and the traction rope 12 is used for pulling the flat plate The trolley walks along the inclined hole.

[0046] The walking wheel 4 is provided with two-sided rims, which are used to ride on the walking track to prevent derailment. Using both sides of the rail, even if the wheels ride on the track to prevent derailment, the height of the rims on both sides is up to 38mm, which effectively solves the problem of derailment. ; The slag truck 10 adopts a dump truck.

[0047] According to the construction characteristics of the project, it is considered that it is suitable for both inclined tunnel section and flat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com