Production technology of high-thermal-shrinkage net

A production process and heat-shrinking technology, which is applied in the direction of textiles, fabrics, open-hole fabrics, etc., to achieve the effects of shortening the production and processing procedures and processes, stable use process, and simple operation on the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

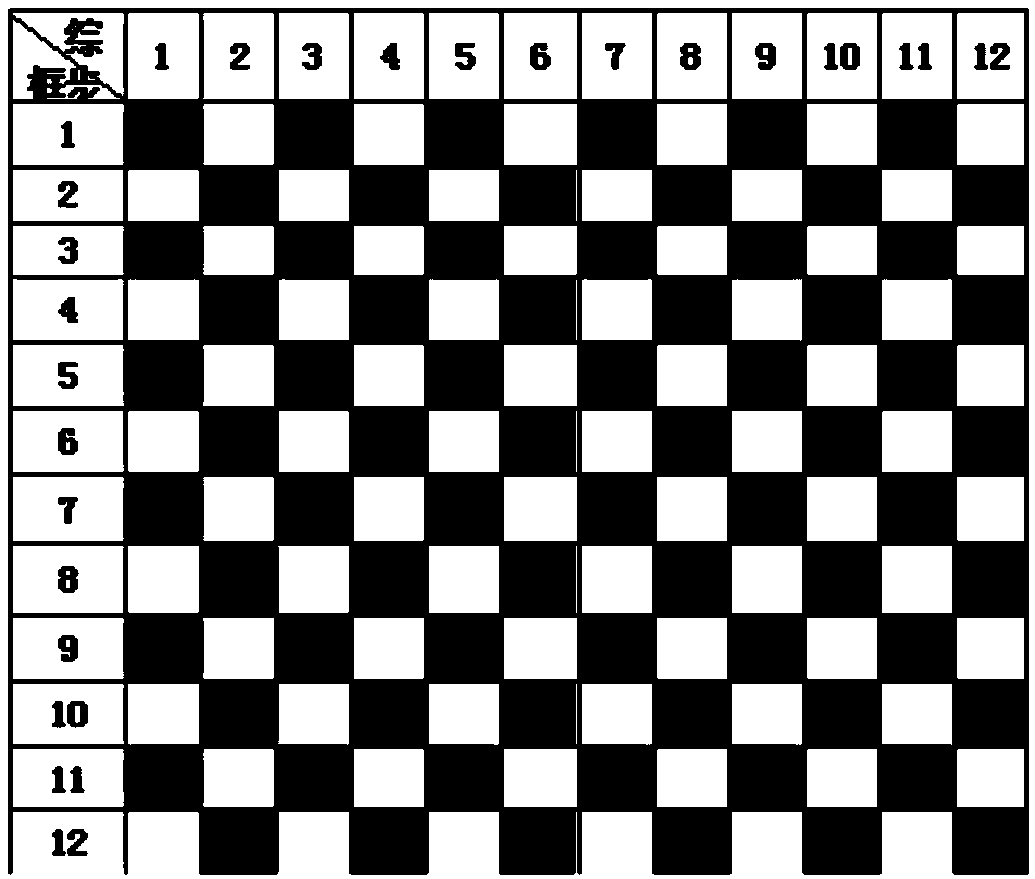

[0048] Example 1: If figure 1 As shown, the organizational structure adopts 1 upper and 1 lower plain weave, the thickness of the mesh body is 1.10-1.25mm, and the weight is 935g / m 2 ±190.

example 2

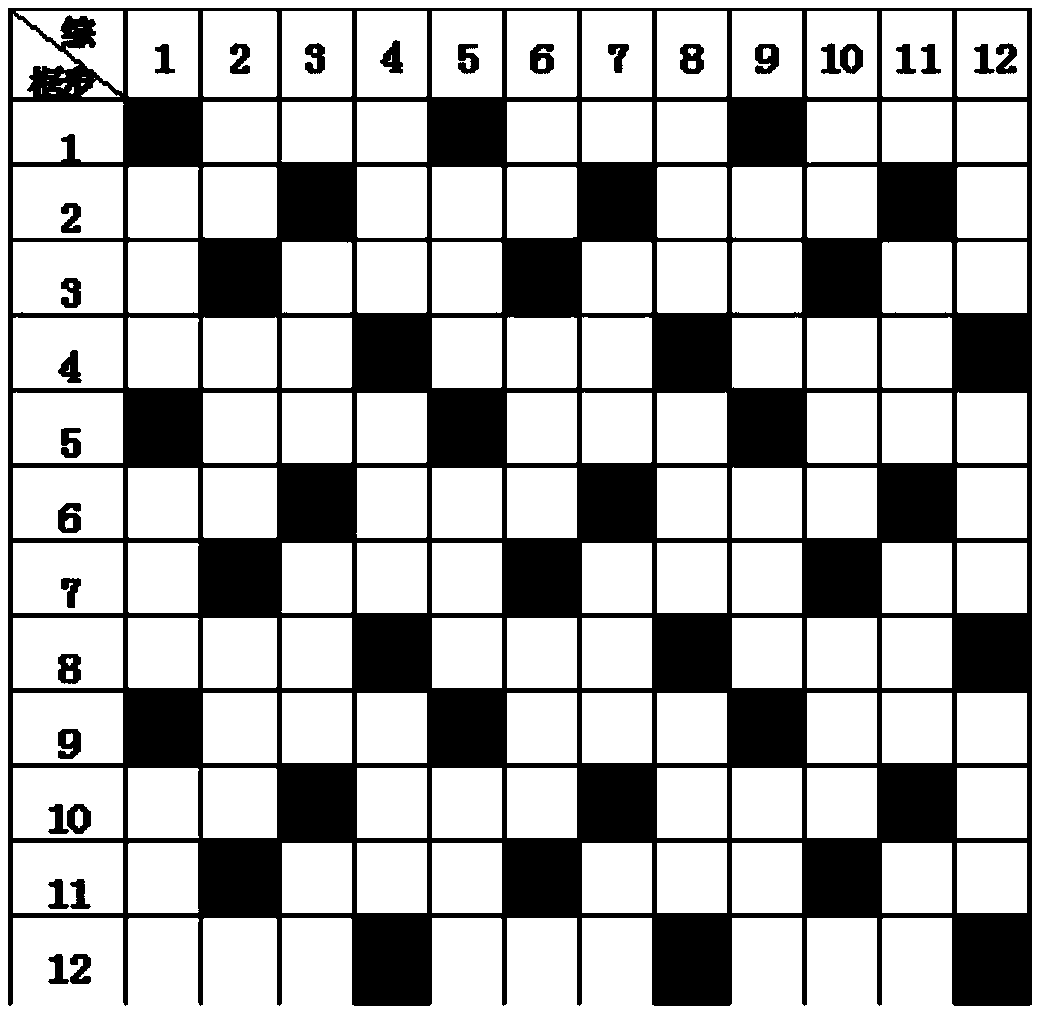

[0049] Example 2: If figure 2 shown. The organizational structure adopts 1 upper and 3 lower plain weaves, the thickness of the mesh body is 1.50-1.65mm, and the weight is 870g / m 2 ±190.

example 3

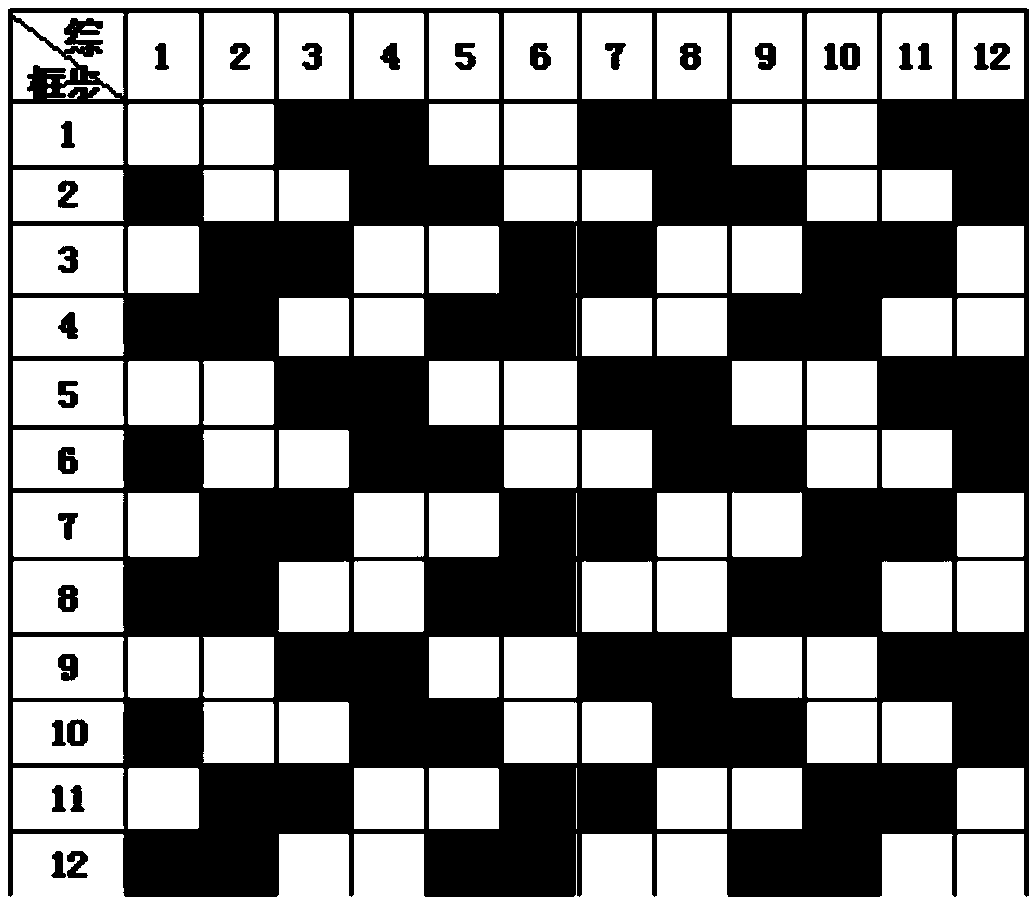

[0050] Example 3: If image 3 , Figure 4 As shown, the organizational structure adopts 2 upper and 2 lower twill weaves, the thickness of the mesh body is 1.30-1.45mm, and the weight is 3325g / m 2 ±380. The herringbone pattern structure is required, and the herringbone pattern (mountain shape) is 40mm-100mm wide.

[0051] (3) Interface processing: check the qualified mesh body, calculate the shrinkage and specification loss in advance according to the specification required by the customer, and then determine the cutting specification, and mark the position of the spiral ring on the mesh surface according to the cutting specification Thread, cut in sections along the direction of the marked line, extract 1-8 weft threads from each incision, and use spiral rings to fill the space left after the weft threads are drawn out at each incision (between 1 and 4 warp threads) ), use 1-6 polyether ether ketone PEEK monofilaments with a diameter of 0.65-0.90mm to pass through the ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com