Soil lifting system and soil lifting method for building deep foundation pit construction in narrow area

A deep foundation pit and area technology, applied in construction, infrastructure engineering, excavation, etc., can solve the problems of difficult excavation of the earthwork under the support, small clear distance between supports, and large internal support area, so as to shorten the construction period and reduce pollution. The effect of small size and simple construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

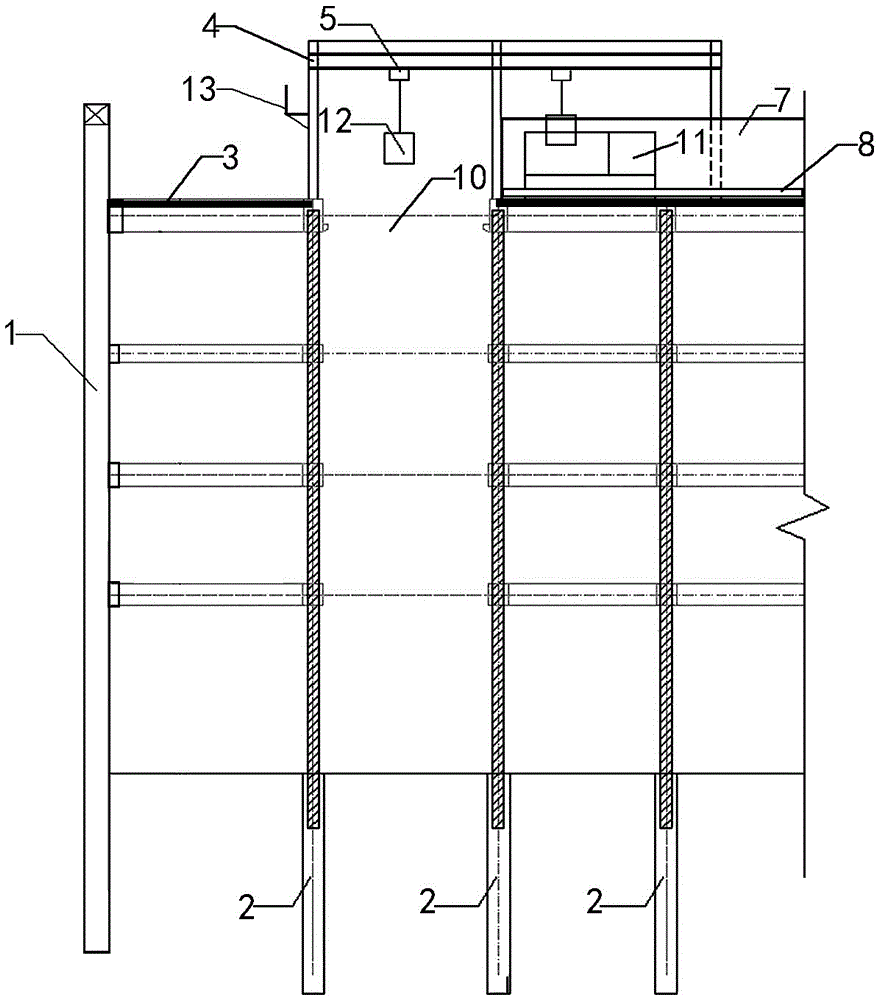

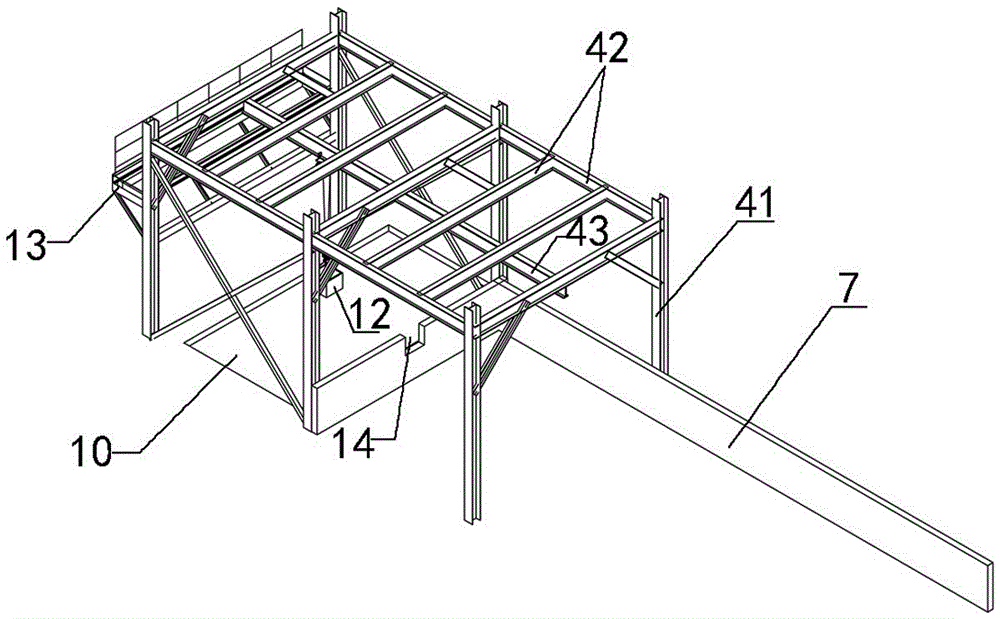

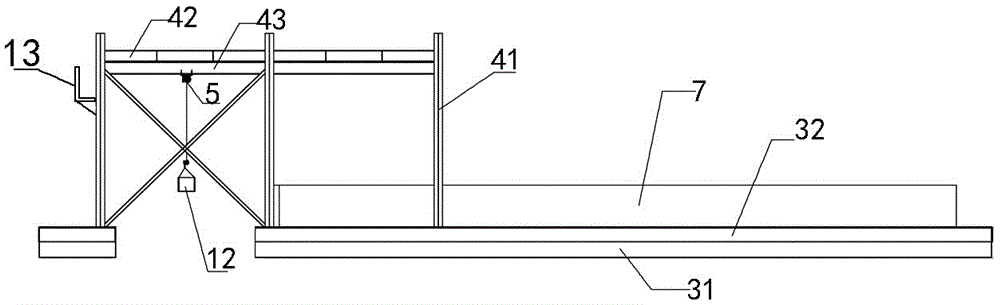

[0051] Such as figure 1, a soil lifting system for deep foundation pit construction in a narrow area, comprising a foundation pit support system, vertical earth lifting equipment and a soil pile platform, the foundation pit support system includes a foundation pit surrounding protection pile 1, a foundation pit column pile 2 and concrete support 3, characterized in that:

[0052] The concrete support 3 includes several roads from top to bottom, and the first concrete support 31 around the hole 10 is used for large-scale sealing, as the first sealing 32 for arranging earth lifting equipment and soil piling platforms; The sealing plate 32 is a reinforced concrete slab with a thickness ranging from 200 to 350 mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com