Outdoor tent fabric with efficient, uvioresistant and heat-insulating coating

A heat-insulating coating and tent fabric technology, applied in tents/canopies, textiles, papermaking, building components, etc., can solve the problem that tents are difficult to meet the yearning for a better outdoor life, sunshade and sunscreen, general anti-ultraviolet effect, poor tent quality To achieve the effect of firm adhesion, good dispersion and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

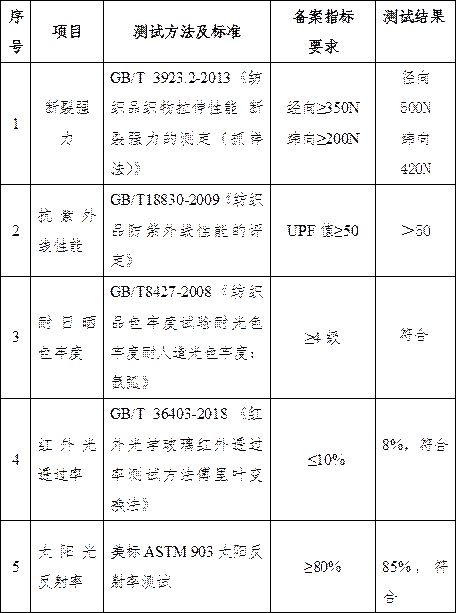

[0017] A high-efficiency anti-ultraviolet heat-insulating coating outdoor tent fabric is prepared by the following steps:

[0018] 1. Embryo preparation:

[0019] Choose polyester filament plain weave fabric, the warp and weft specifications are 50D / 36F, and the warp and weft density should reach more than 204 threads / foot, and the gray fabric should be seamed.

[0020] 2. Desizing and dyeing:

[0021] Put the connected base embryo into the overflow dyeing machine for desizing and dyeing, and then restore and wash after the color matching. The color fastness is above grade 4.

[0022] Three, stereotyped waterproof:

[0023] After desizing and dyeing, the base embryo is subjected to stereotype and waterproof treatment. The oven temperature of the stereotype machine is set at 200°C, and the oven stays for 30 seconds. At the same time, fluorocarbon waterproof agent CPS-L 38G / L is added, and the water-wetting effect after waterproof treatment can be tested up to Level 5 or abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com