A kind of pvc-u drainage pipe fitting and its preparation method and application

A technology of PVC-U and drainage pipe fittings, applied in the field of drainage pipe fittings, can solve the problems of easy scaling, insufficient antibacterial and anti-mildew effects, and difficult scaling, etc., to achieve air barrier, anti-bacterial and anti-mildew ability balance, and prevent aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1

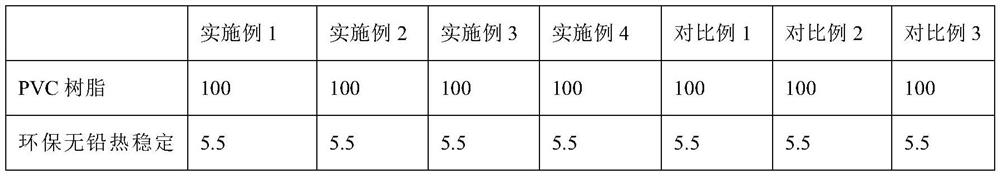

[0068] A PVC-U drainage pipe fitting, including the components calculated in parts by weight as shown in Table 1 below.

[0069] The components and parts by weight of the PVC-U drainage pipe fittings of each embodiment and comparative example in table 1

[0070]

[0071]

[0072] The preparation method of above-mentioned PVC-U drainage pipe fitting, comprises the steps:

[0073] S1. After mixing according to the ingredients of each raw material, add it to a high-speed hot mixer for high-temperature and high-speed kneading and dispersion. When the temperature reaches 115°C, transfer to a cold mixer to stir and cool at a low speed. When the temperature drops below 55°C, discharge it into Hopper, ready for use;

[0074] S2. Add the ready-to-use mixed ingredients in the hopper described in S1 to a twin-screw extruder for plasticization, extrude and granulate, pelletize, cool in a vibrating tower, and pack the pellets; the twin-screw extruder is anisotropic parallel For the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com