Activated carbon-loaded polyphenylene sulfide porous fiber and its preparation method and application

A technology of polyphenylene sulfide and porous fibers, applied in the field of activated carbon-loaded polyphenylene sulfide porous fibers and their preparation, can solve the problems of poor acid and alkali corrosion resistance, poor organic solvent resistance, poor adsorption effect, etc., and achieve excellent flame retardant performance, the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

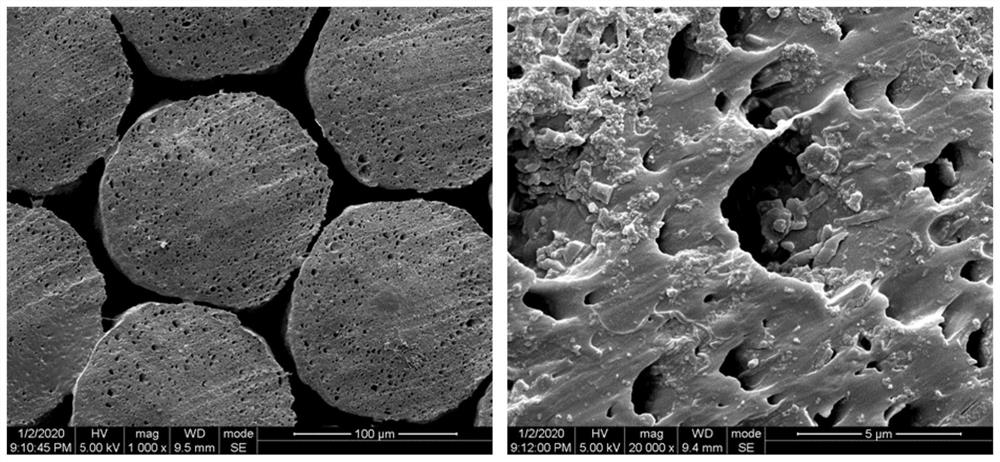

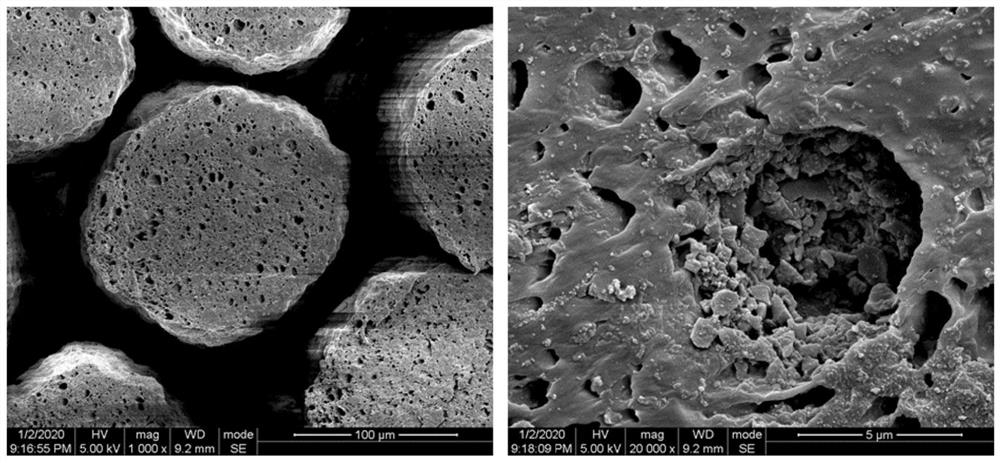

Image

Examples

preparation example Construction

[0027] Some embodiments of the present invention also provide a kind of preparation method of activated carbon-loaded polyphenylene sulfide porous fiber, it comprises:

[0028] The ternary blending resin extruded by melt blending is spun through a melt spinning machine to obtain ternary blending primary fibers, wherein the ternary blending resin is composed of polyphenylene sulfide resin, porogen Melt blending and extruding with nano-activated carbon; heat-stretching and heat-setting the ternary blending as-spun fibers in sequence to obtain a ternary blending fiber; after dissolving and removing the porogen in the ternary blending fiber, The activated carbon-loaded polyphenylene sulfide porous fiber is obtained.

[0029] In order to solve the problem that activated carbon is loaded and embedded in the matrix structure, resulting in poor adsorption performance and its own material performance, after a lot of practice and research, the inventor creatively proposed the combinatio...

Embodiment 1

[0053] The preparation method of the polyphenylene sulfide porous fiber loaded with 5wt% activated carbon provided by the present embodiment is:

[0054] Mix polyphenylene sulfide resin and nano-activated carbon at a mass ratio of 95:5, and then uniformly mix it with polyethersulfone at a mass ratio of 60:40, and then dry it in a vacuum oven at 140°C for 5 hours . After the drying is completed, it is sent to a twin-screw extruder with a die head temperature of 300° C. for melt blending, and the extruded filaments are pelletized to obtain spinning raw materials.

[0055] Send the obtained spinning raw material into a single-screw melt spinning machine for spinning, the spinning temperature is 320°C, the number of spinneret holes used is 18 holes, and the diameter of the spinneret holes is 0.4mm; a thin stream of melt is sprayed out After being cooled and solidified by side air blowing, the polyphenylene sulfide / polyethersulfone / activated carbon ternary blend primary fiber was ...

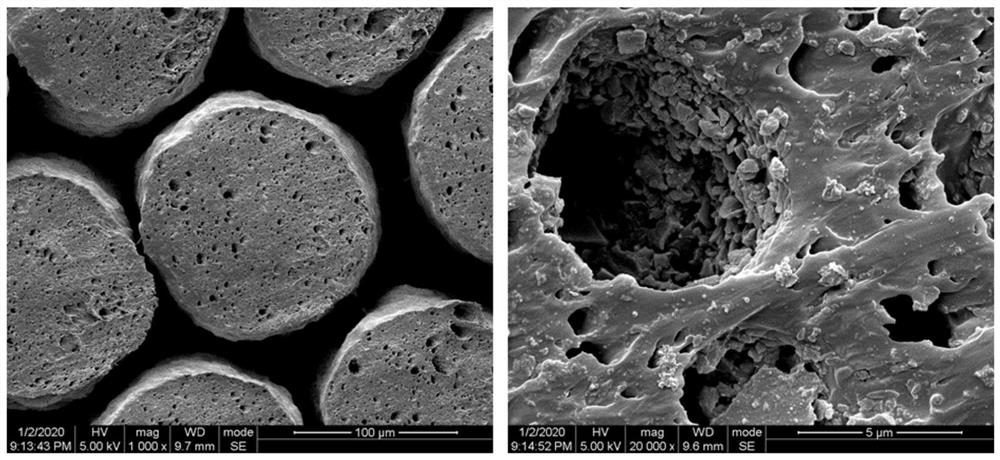

Embodiment 2

[0060] The preparation method of the polyphenylene sulfide porous fiber loaded with 10wt% activated carbon provided by the present embodiment is:

[0061] Mix polyphenylene sulfide resin and nano-activated carbon at a mass ratio of 90:10, and then uniformly mix it with polyethersulfone at a mass ratio of 60:40, and then dry it in a vacuum oven at 140°C for 5 hours . After the drying is completed, it is sent to a twin-screw extruder with a die head temperature of 300° C. for melt blending, and the extruded filaments are pelletized to obtain spinning raw materials.

[0062] Send the obtained spinning raw material into a single-screw melt spinning machine for spinning, the spinning temperature is 320°C, the number of spinneret holes used is 18 holes, and the diameter of the spinneret holes is 0.4mm; a thin stream of melt is sprayed out After being cooled and solidified by side air blowing, the polyphenylene sulfide / polyethersulfone / activated carbon ternary blend primary fiber wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com