A kind of high wear-resisting and high shock-absorbing sports shoe sole material and preparation method thereof

A technology for sole materials and sports shoes, applied in the field of sports shoes, can solve the problems of not meeting the requirements of lightness, general tear strength, general rebound rate, etc., and achieve good compression resistance and recovery, good comprehensive physical properties, and excellent flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

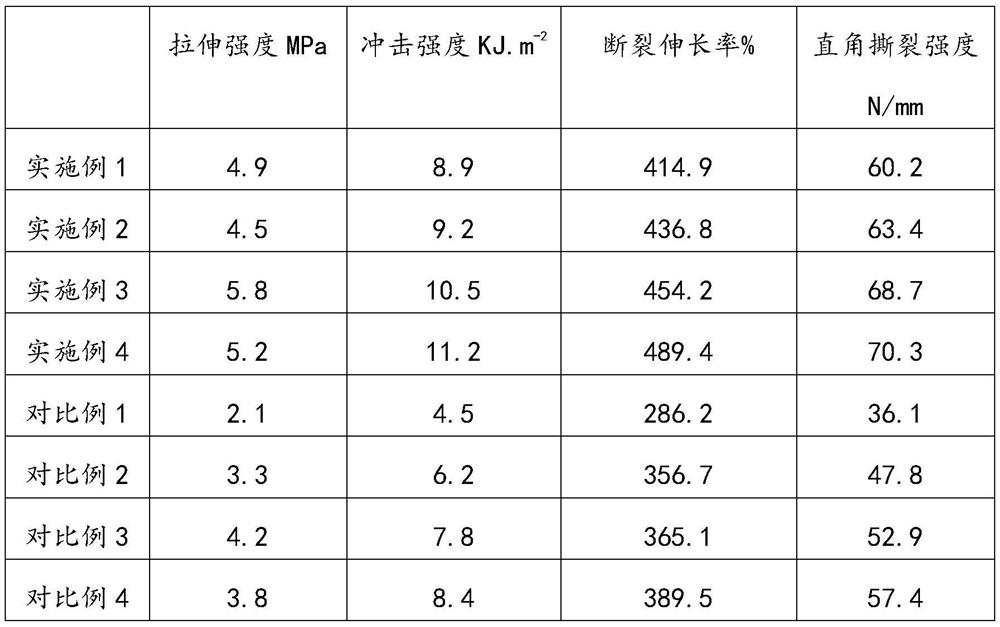

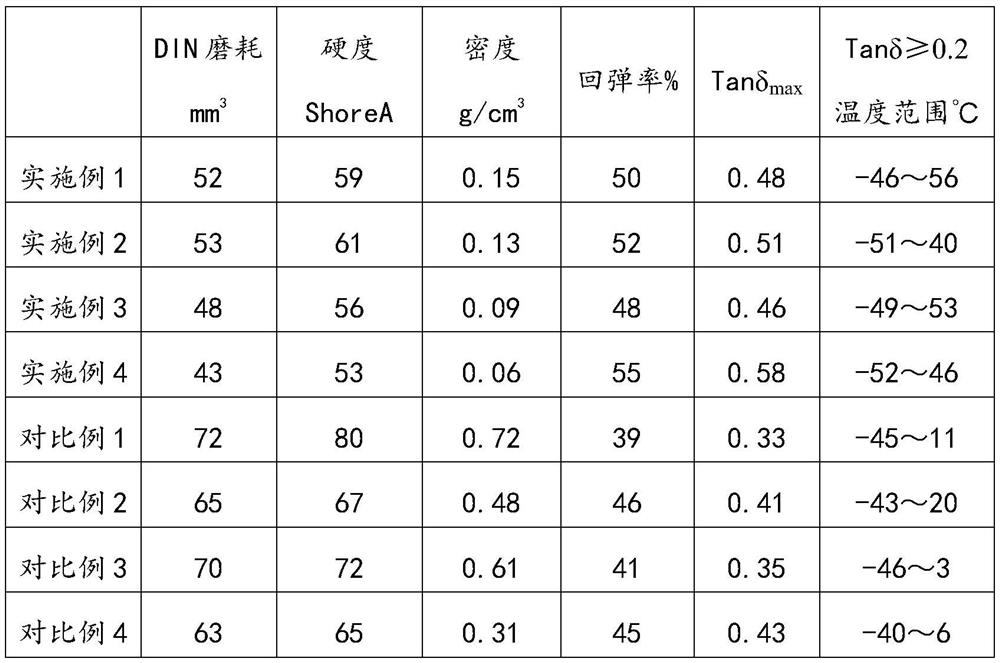

Examples

Embodiment 1

[0032] A high-wear-resisting and high-shock-absorbing sole material for sports shoes, the sole material is composed of the following raw materials by weight: 40 parts of ethylene-vinyl acetate copolymer, 2 parts of modified nano-zinc oxide, 20 parts of PBSs, 40 parts of PBS Polyester thermoplastic polyurethane elastomer, 8 parts of waste rubber powder, 8 parts of modified diatomaceous earth, 3 parts of ligand type titanate coupling agent, 3 parts of foaming agent, 1 part of crosslinking agent, 3 parts of vulcanizing agent and 0.8 parts antioxidant. According to the preparation method of the sole material composed of the above-mentioned materials, it specifically comprises the following steps:

[0033] (1) EVA / PBSs copolymer: add EVA to the double-roll mill, heat up to 100°C, add PBSs after the EVA is completely melted, mix for 30min, then raise the temperature to 160°C, add modified nano-oxidation Zinc and cross-linking agent were mixed for 1 hour, and the tablet was removed ...

Embodiment 2

[0041] A high-wear-resistance and high-shock-absorbing sole material for sports shoes, the sole material is composed of the following raw materials by weight: 60 parts of ethylene-vinyl acetate copolymer, 5 parts of modified nano-zinc oxide, 10 parts of PBSs, 25 parts of PBS Polyester thermoplastic polyurethane elastomer, 10 parts of waste rubber powder, 12 parts of modified diatomaceous earth, 1 part of ligand type titanate coupling agent, 5 parts of azodicarboxylate, 2 parts of diisopropyl peroxide Benzene, 1 part benzoyl peroxide and 0.3 part antioxidant AW. The preparation method of the sole material composed of this material is the same as that in Example 1, and the specific reference is made to Example 1.

[0042] The VA content in the above-mentioned EVA ethylene-vinyl acetate copolymer is 22-36%, and the polyester thermoplastic polyurethane elastomer is Elastollan C64D from BASF, Germany.

[0043] The preparation method of the above-mentioned modified nano-zinc oxide ...

Embodiment 3

[0047] A high-wear-resistance and high-shock-absorbing sole material for sports shoes, the sole material is composed of the following raw materials by weight: 50 parts of ethylene-vinyl acetate copolymer, 3 parts of modified nano-zinc oxide, 15 parts of PBSs, 34 parts of PBS Polyester thermoplastic polyurethane elastomer, 8 parts of waste rubber powder, 10 parts of modified diatomaceous earth, 2 parts of ligand type titanate coupling agent, 4 parts of azodicarboxylate, 1.5 parts of diisopropyl peroxide Benzene, 2 parts benzoyl peroxide and 0.5 part antioxidant AW. The preparation method of the sole material composed of this material is the same as that in Example 1, and the specific reference is made to Example 1.

[0048] The VA content in the above-mentioned EVA ethylene-vinyl acetate copolymer is 22-36%, and the polyester thermoplastic polyurethane elastomer is Elastollan C64D from BASF, Germany.

[0049] The preparation method of the above-mentioned modified nano-zinc oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com