Linear high-molecular-weight modified polyester emulsion, preparation method thereof and application of linear high-molecular-weight modified polyester emulsion in glass fiber impregnating compound

A modified polyester, high molecular weight technology, applied in linear high molecular weight modified polyester emulsion and its preparation, application field of glass fiber sizing agent, can solve the problem of low molecular weight of polyester emulsion, poor emulsion stability, glass fiber Problems such as poor wettability, to achieve the effect of good solubility, high stiffness and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

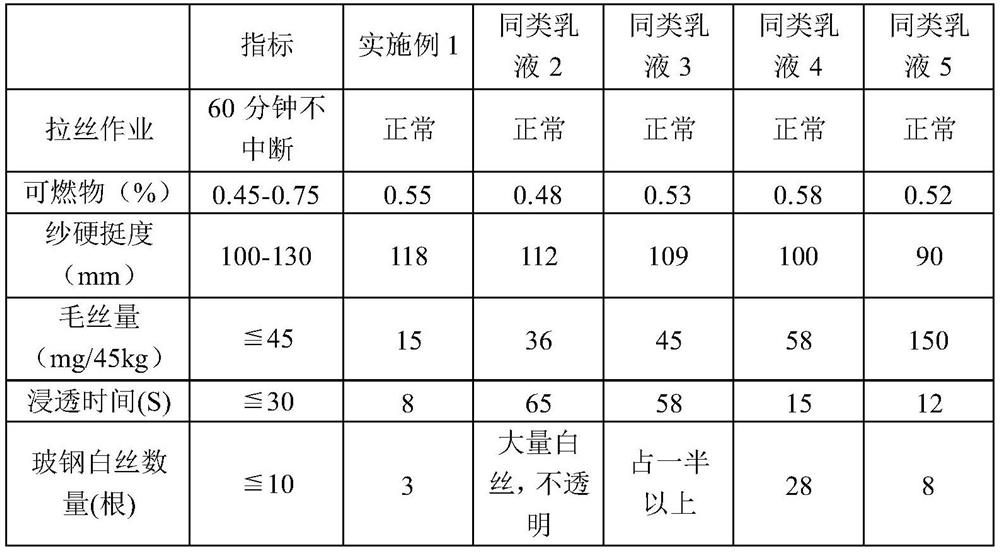

Embodiment 1

[0031] The preparation method of linear high molecular weight modified polyester emulsion comprises the steps:

[0032](1) Preparation of unsaturated polyester resin: put adipic acid, fumaric acid, ethoxylated bisphenol A, and propoxylated bisphenol A into the oil heater with a molar ratio of 3:1:2:2.15. Stirring, in the reaction kettle of the vertical condenser and the horizontal condenser, add 0.1% methyl hydroquinone and 0.08% organotin compound of the total mass of the material, close the feeding port, open the cooling water of the vertical condenser, open the oil Heater, after 1.3 hours, raise the temperature to 115°C until all the materials are completely melted, turn on the stirring motor, and pass nitrogen; continue to heat up to 145°C after 1.5 hours, turn off the cooling water of the vertical condenser, and turn on the cooling of the horizontal condenser Water, start to drain, slowly heat up to 200°C for 5.5 hours, start to keep warm, the highest temperature during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com